An Intelligent Busway Conversion Mechanism

A technology of conversion mechanism and bus duct, applied in the field of bus duct, can solve the problems of easy inclination of alignment, lack of stability, reduced installation efficiency of staff, etc., and achieve the effect of increasing stability and stable design structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

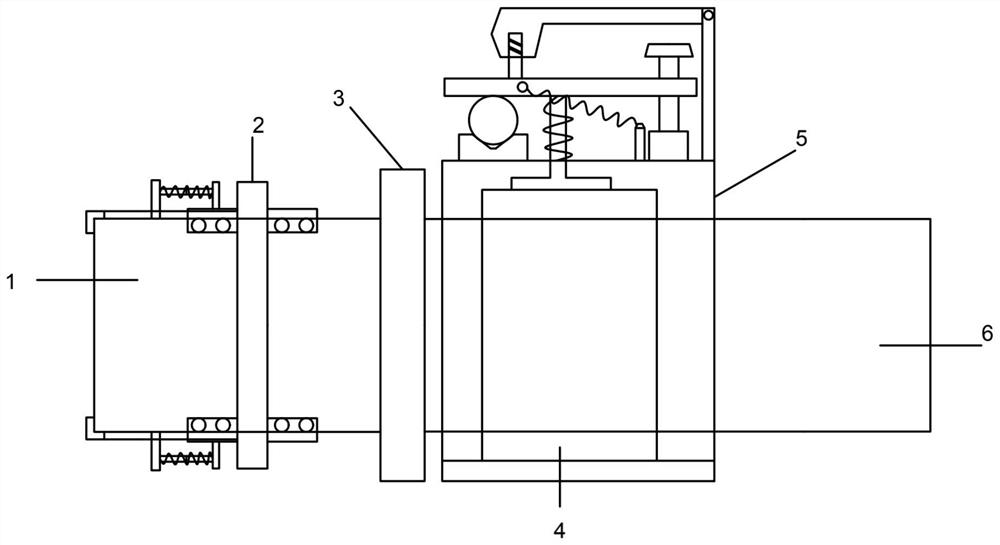

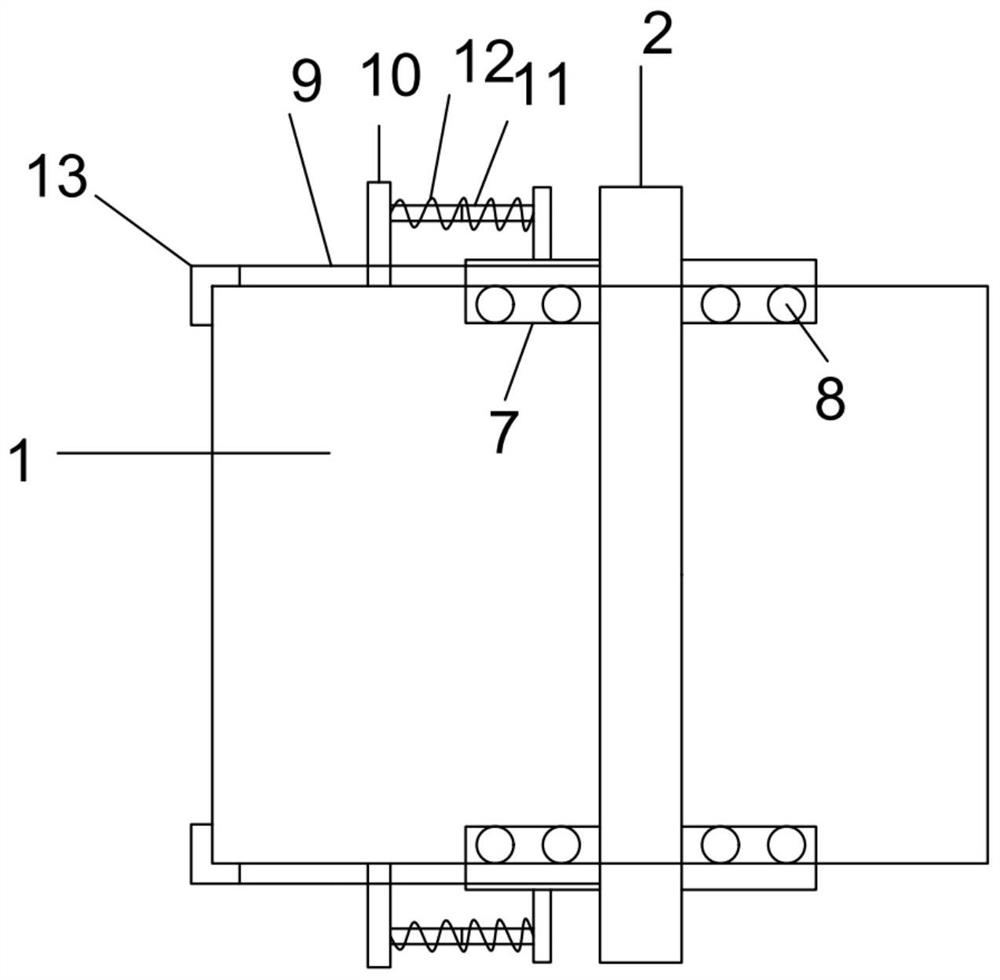

[0028] like Figure 1-5 As shown, an intelligent busway conversion mechanism includes a casting busbar 1, a side block 3 and a housing 5, a constraining frame 2 is sleeved on the casting busbar 1, and at least one side plate 7 is provided on both sides of the constraining frame 2, A first spring 8 is arranged on one side of the side plate 7, a casting bus 1 is arranged between the first springs 8, a pull rod 9 is slidably arranged on the top of the side plate 7, a mounting rod 10 is provided on the top of the pull rod 9, and one side of the mounting rod 10 is provided. There is a telescopic rod 11 , a second spring 12 is wound around the telescopic rod 11 , a top block is provided on one side of the telescopic rod 11 , and the top block is connected with the side plate 7 , and one end of the pull rod 9 is provided with an adapter block 13 .

[0029] The working principle of this embodiment:

[0030] Constraining frames 2 are sleeved on a plurality of pouring busbars 1. Side p...

Embodiment 2

[0032] like Figure 1-5 As shown, side blocks 3 are provided on both sides of the casting busbar 1, a transverse plate 24 is provided between the side blocks 3, a sliding rail 25 is provided on the top of the transverse plate 24, and at least one spring block 26 is provided on the sliding rail 25. There is a casting bus 1 between the blocks 26, a connecting block is provided on one side of the side block 3, and inserting rods 27 are provided on both sides of the bottom of the horizontal plate 24. A fifth spring 28 is provided between the connecting block and the fixing block 29; a side groove is provided on one side of the side block 3, and a plugging rod 31 is provided in the side groove, and a bending rod 30 is slid on the plugging rod 31. The bending rod 30 is connected with the horizontal plate 24 , and a sixth spring 32 is wound around the insertion rod 31 .

[0033] The working principle of this embodiment:

[0034] The side blocks 3 are arranged on both sides of the c...

Embodiment 3

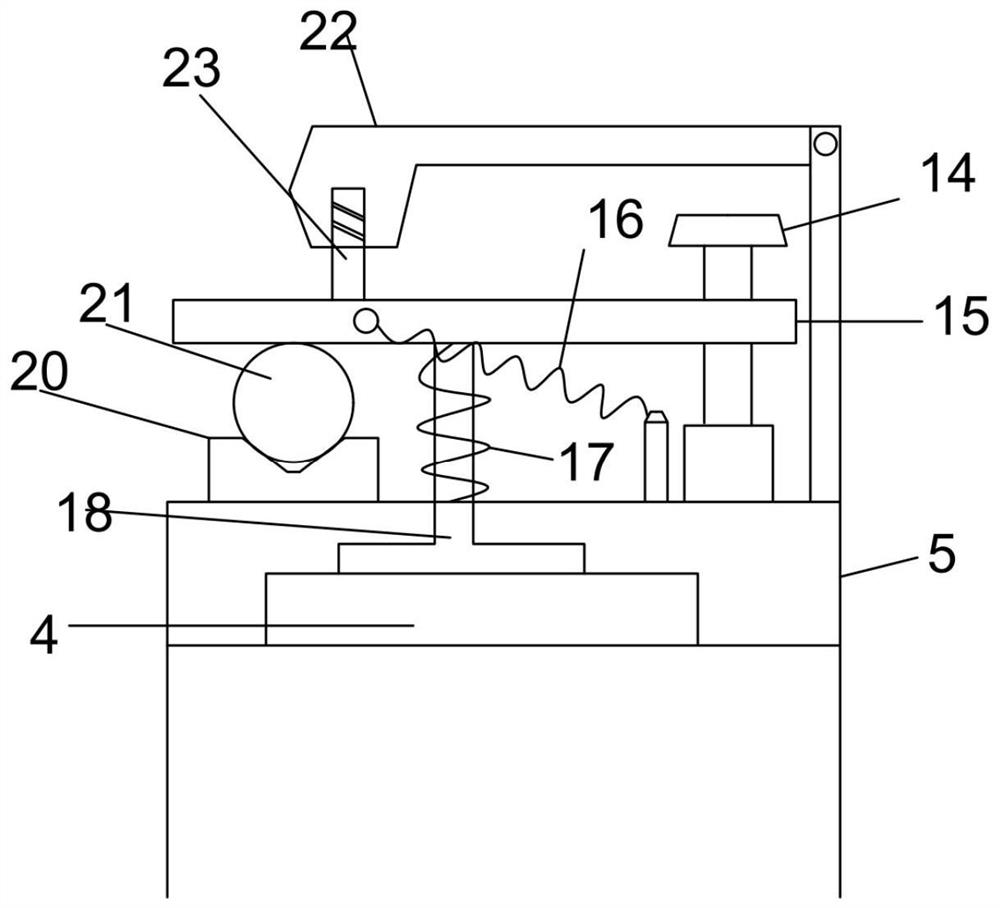

[0036] like Figure 1-5 As shown, a transition busbar 4 is sleeved on the casting bus 1, a casing 5 is sleeved on the transition busbar 4, a threaded rod 14 is provided on the top of the casing 5, and a lifting plate 15 is arranged on the threaded rod 14. The lifting plate 15 A pressure plate 18 is arranged at the bottom, a fourth spring 17 is arranged between the pressure plate 18 and the casing 5, a transition busbar 4 is arranged on the side of the pressure plate 18 passing through the casing 5, and a second spring 17 is arranged between the lifting plate 15 and the casing 5. Three springs 16;

[0037] A straight rod is provided on one side of the top of the housing 5 , a rotary pressure plate 22 is provided on the top of the straight rod, and a clamping piece 23 is provided on the top of the lifting plate 15 , and a rotary pressure plate 22 is provided between the clamping pieces 23 . The top of the housing 5 is provided with a cushion block 20 , the top of the cushion bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com