Savoury composition

A composition, salty and fresh technology, applied in the direction of food science, table utensils, home utensils, etc., can solve the problems of unstable components, no appetite, soft properties of cooking aids, easy to sag and flatten, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] A method for preparing a savory food for preparing soup or broth is provided, comprising the steps of:

[0035] i) preparing a savory composition comprising edible salt, fat, vegetable matter and sugar or polysaccharide,

[0036] ii) filling a mold with said savory composition and placing an elongated member in said mold such that said elongated member extends from said mould,

[0037] iii) heating the mold containing the savory composition and the elongated member at a temperature of 70 to 140° C. in the presence of moisture,

[0038] iv) cooling the mold and removing the savory composition and elongated member from the mold to provide a savory food product.

[0039] Preferably, the savory composition is provided by mixing dry ingredients (typically edible salt and vegetable matter) with fat (if present) in molten state followed by sugar or polysaccharides.

[0040] Preferably, the savory composition is prepared by mixing edible salt selected from sodium chloride, po...

Embodiment 1

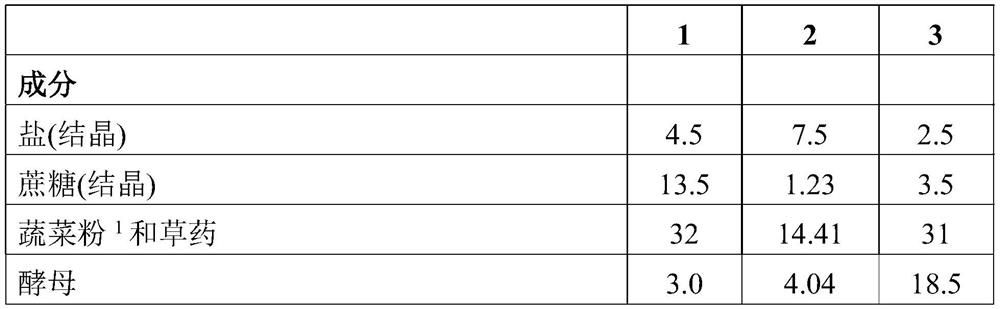

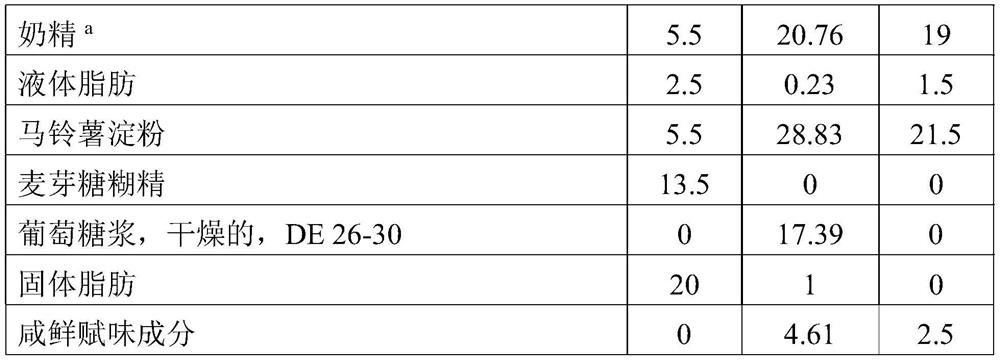

[0123] According to the recipe in Table 1, the savory and fresh composition was prepared.

[0124] Table 1

[0125]

[0126]

[0127] a: 75% fat;

[0128] 1 Vegetable powder, in composition 1: tomato; in composition 2: mushrooms; in composition 3: pumpkin

[0129] First, a base mixture of salt, vegetable powder, yeast, creamer, fat powder, herbs and potato starch is mixed together in a Thermomix (Thermomix 31-1, max. speed 10.700 / min).

[0130] Fill the silicon mold with the savory composition of Table 1 Sample 1. Place wooden sticks in the composition so that the sticks extend from the mold. The mold was covered with a complementary mold, pressed and heated in a Convectormat (with or without steam injection) according to Table 2. Heat at indicated temperature for 6 minutes. Thereafter, the savory food is allowed to cool and removed from the mold.

[0131] Table 2

[0132] sample temperature steam result 2.1 70℃ Have solid product 2.2...

Embodiment 3

[0134] The savory food (sample 1) of the present invention was prepared as above, and compared with the savory food (composition A) of WO0247519, the dissolution test was carried out. Composition A was prepared according to Examples 1 and 3 of WO0247519.

[0135] Table 4

[0136]

[0137]

[0138] Put savory food 1 and A in the cup. Bring water to a boil in a pot. Measure the required amount of water (200ml) into the measuring cup and transfer from there to each cup individually. The savory food is held by the stick and stirred until dissolved.

[0139] table 5

[0140] Savory food Dissolution time Exterior 1 60 seconds fat free eye A 99 seconds fat eye

[0141] Savory Food 1 was visually appealing before being placed in hot water, dissolving quickly and without developing fatty eyes, which meant that the resulting soup was also visually appealing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com