Steel sheet rolling method and steel sheet manufacturing method

A technology of steel plate and rolling process, which is applied in the field of steel plate rolling and steel plate manufacturing, and can solve problems such as inability to properly control the shape change of work roll 2, poor control of work roll 2, and insufficient cooling of work roll 2

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

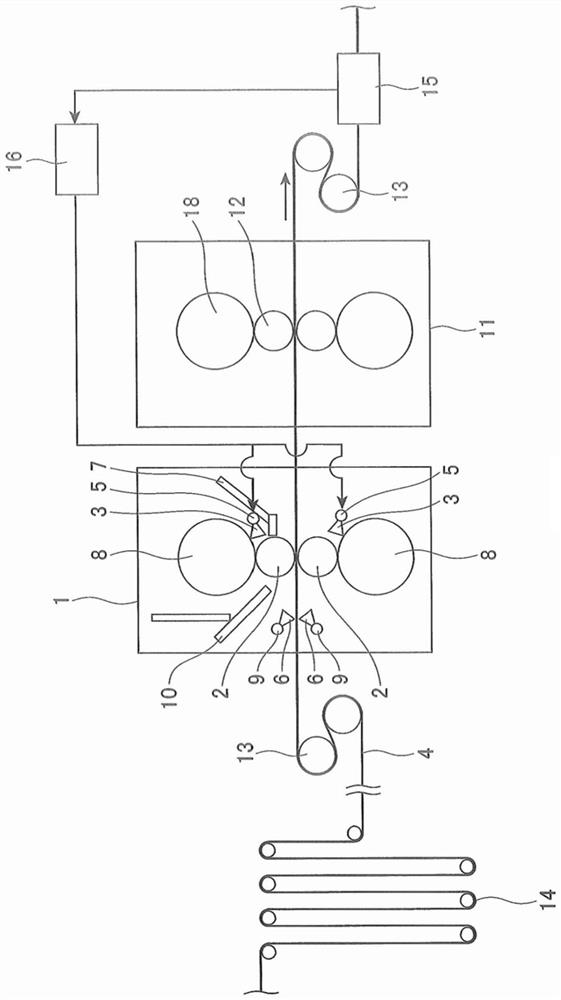

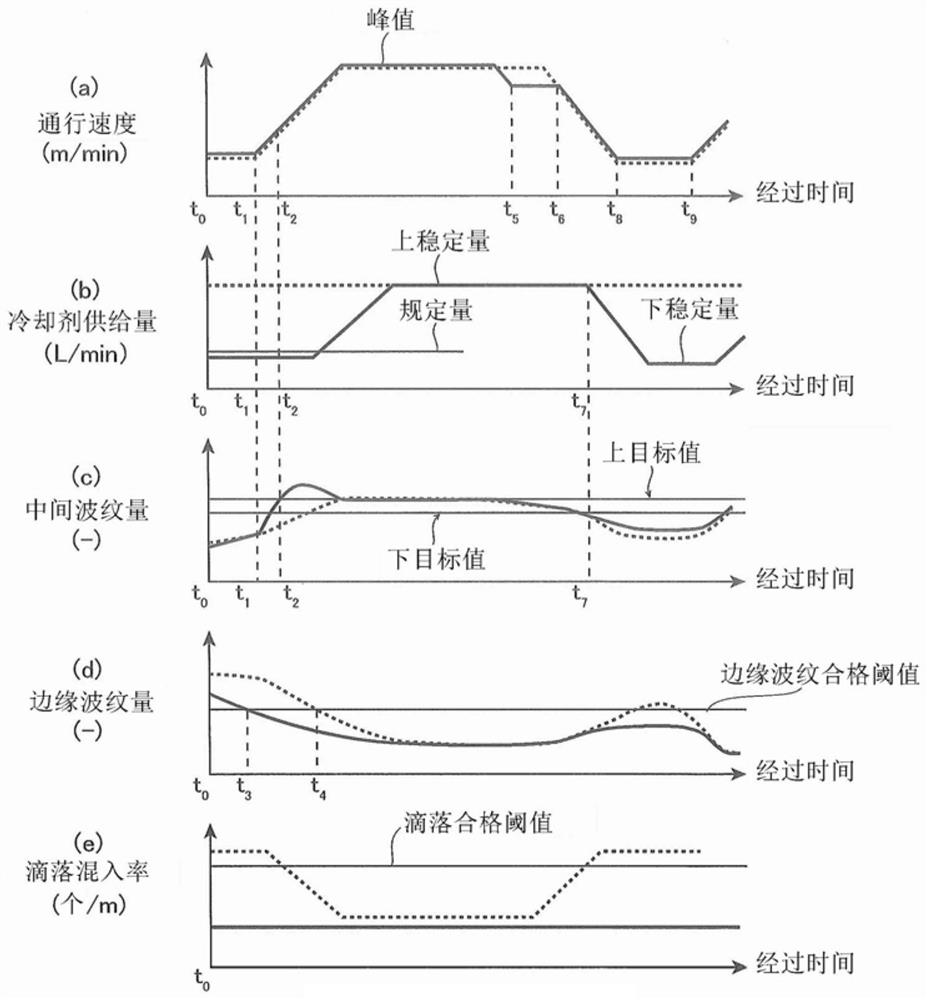

[0060] In the actual cold rolling production line, the quench and temper rolling mill (with the figure 1 In the same structure), the rolling method of the steel plate according to the present invention is applied. The thickness of the steel plate to be rolled is 0.150 mm and 0.160 mm, and the width of the plate is 900 mm. As an example of the present invention, such as image 3 As shown by the solid line of , the supply amount of the coolant is adjusted. On the other hand, as a comparative example, such as image 3 As shown by the dotted line, the supply amount of coolant during rolling is kept constant for the upper stable amount. For the coils obtained after the secondary cold rolling (20 coils in total), the ratio of the length of the coils with a portion having a shape defect due to center waviness or edge waviness and the appearance defect caused by dripping were obtained. The ratio of the length of the section to the coil.

[0061] In the example of the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com