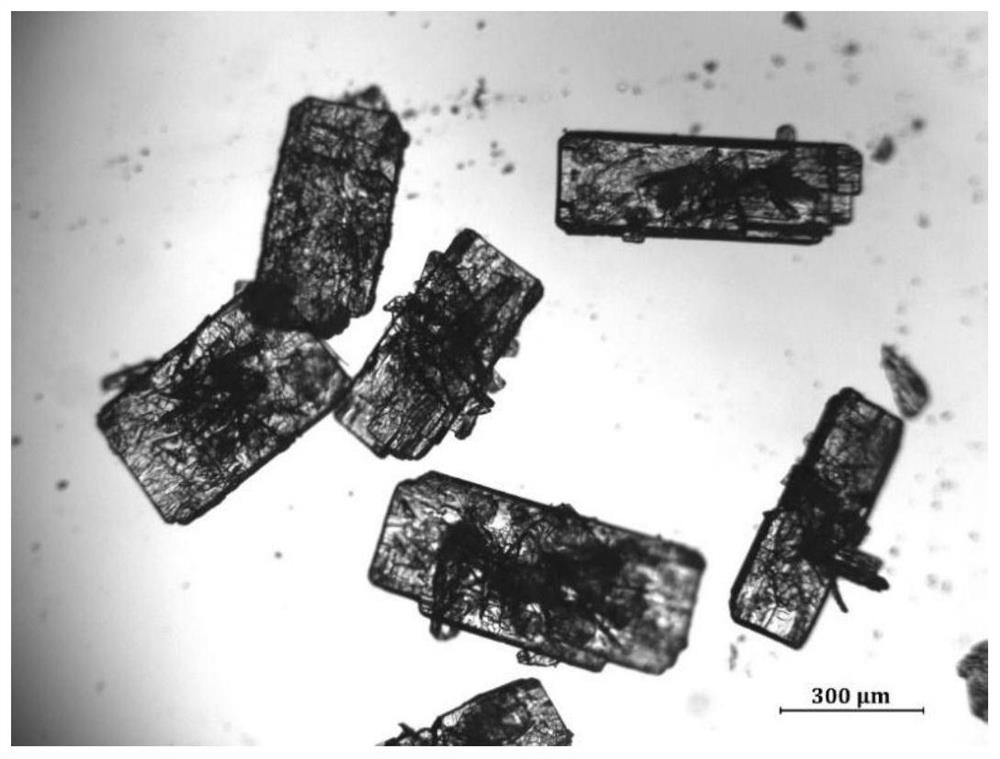

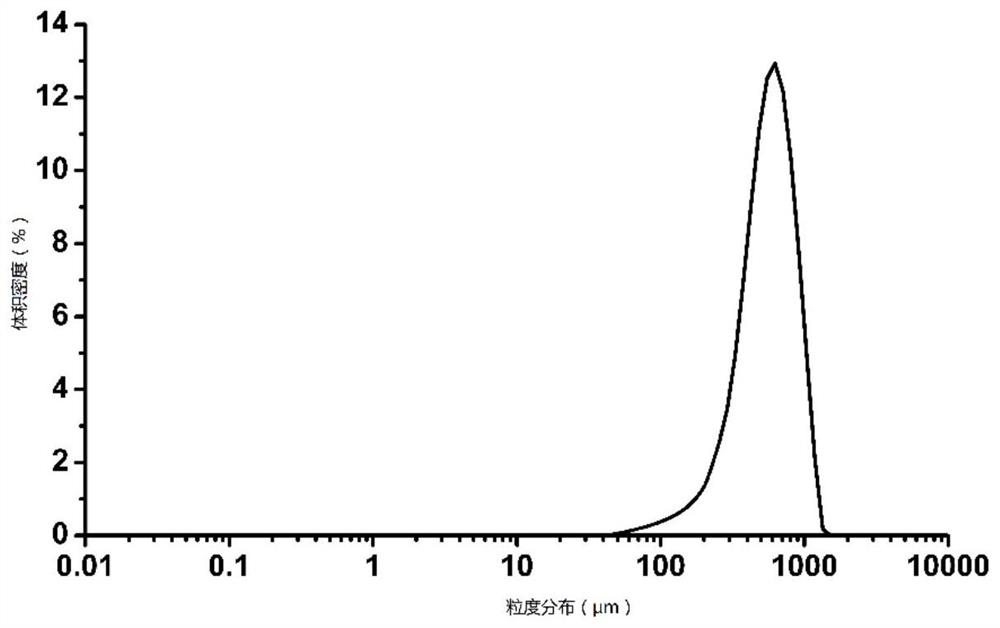

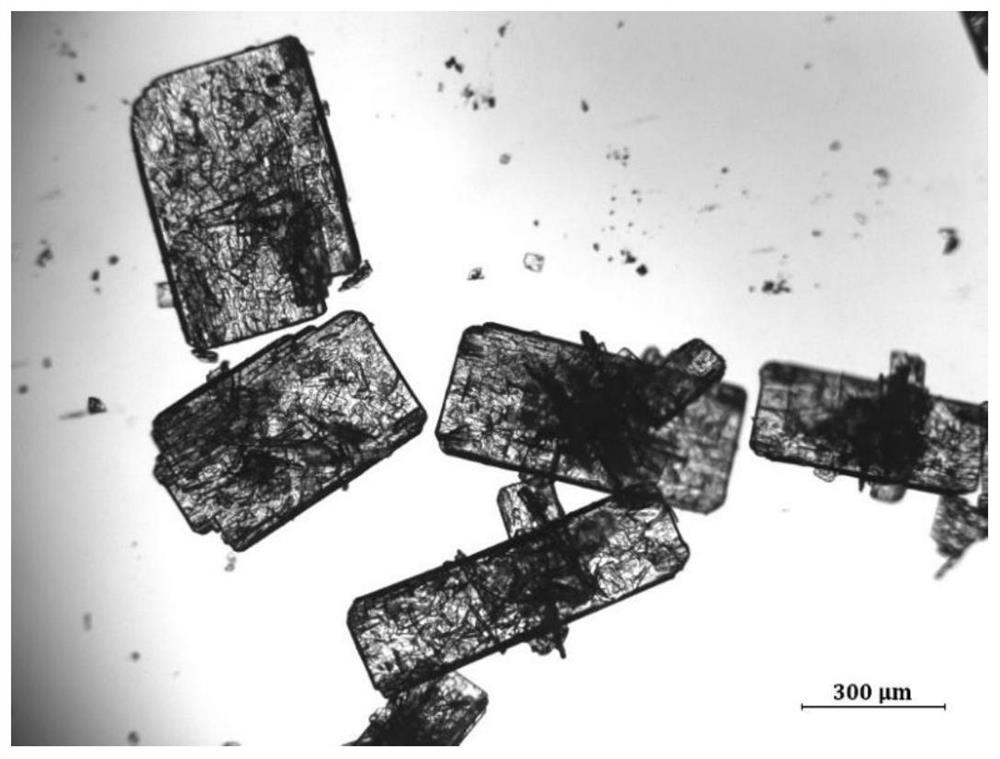

A preparation method for improving the fluidity of L-carnitine fumarate

A technology of L-carnitine fumarate and solution, which is applied in the fields of medicine, health care and food. It can solve the problems of easy coalescence and poor fluidity of L-carnitine fumarate, and achieves inhibition of coalescence and excellent fluidity , Weaken the effect of adsorption/stacking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] (1) Mix 12.70g of L-carnitine inner salt (L-carnitine) with 9.14g of fumaric acid, add to the mixed solvent of water-ethanol (8.5g of distilled water+79.0g of absolute ethanol), and dissolve the suspension The temperature was raised to 77°C. The solid is completely dissolved to obtain L-carnitine fumarate solution;

[0046] (2) The solution is subjected to the cooling crystallization of the first stage, under the action of stirring (rotating speed is set to 600rpm), the L-carnitine fumarate solution is cooled to 71°C at a speed of 18°C / hour, and an amount of solute equivalent to 1.75g of 80-mesh seed crystal with a mass of 8.0%, and apply an ultrasonic field with a frequency of 60kHz for 5 minutes, and keep warm for 0.5 hours;

[0047] (3) The L-carnitine fumarate solution through step (2) is subjected to the cooling crystallization of the second stage, under stirring (rotating speed is set to 600rpm), the L-carnitine fumarate is mixed with the speed of 3° C. / hour C...

Embodiment 2

[0051] (1) Mix 8.84g of L-carnitine inner salt (L-carnitine) with 6.36g of fumaric acid, add to the mixed solvent of water-ethanol (6.2g of distilled water+63.2g of absolute ethanol), and dissolve the suspension The temperature was raised to 75°C. The solid is completely dissolved to obtain L-carnitine fumarate solution;

[0052] (2) The solution is subjected to the cooling crystallization of the first stage, under stirring (rotating speed is set to 500rpm), the L-carnitine fumarate solution is cooled to 68°C at a speed of 24°C / hour, and an amount of solute equivalent to 1.06g of 100-mesh seed crystal with a mass of 7.0%, and apply an ultrasonic field with a frequency of 50kHz for 10 minutes, and keep warm for 1 hour;

[0053] (3) Carry out the cooling crystallization of the second stage through the L-carnitine fumarate solution of step (2), under the action of stirring (rotating speed is set as 500rpm), with the speed of 5 ℃ / hour, L-carnitine fumarate Cool the salt solution...

Embodiment 3

[0057] (1) Mix 6.22g of L-carnitine inner salt (L-carnitine) with 4.47g of fumaric acid, add to the mixed solvent of water-ethanol (3.8g of distilled water+47.4g of absolute ethanol), and dissolve the suspension The temperature was raised to 72°C. The solid is completely dissolved to obtain L-carnitine fumarate solution;

[0058] (2) The solution is subjected to the cooling crystallization of the first stage, under stirring (rotating speed is set to 400rpm), the L-carnitine fumarate solution is cooled to 66°C at a speed of 30°C / hour, and an amount of solute equivalent to 0.64g of 120-mesh seed crystal with a mass of 6.0%, and apply an ultrasonic field with a frequency of 40kHz for 15 minutes, and keep warm for 1.5 hours;

[0059] (3) Carry out the cooling crystallization of the second stage through the L-carnitine fumarate solution of step (2), under the action of stirring (rotating speed is set as 400rpm), with the speed of 6 ℃ / hour, L-carnitine fumarate Cool the salt solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com