Rolling control apparatus and a method for controlling rolling

A control device and technology for rolled products, applied in the direction of profile control, etc., can solve problems such as difficult to deal with

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

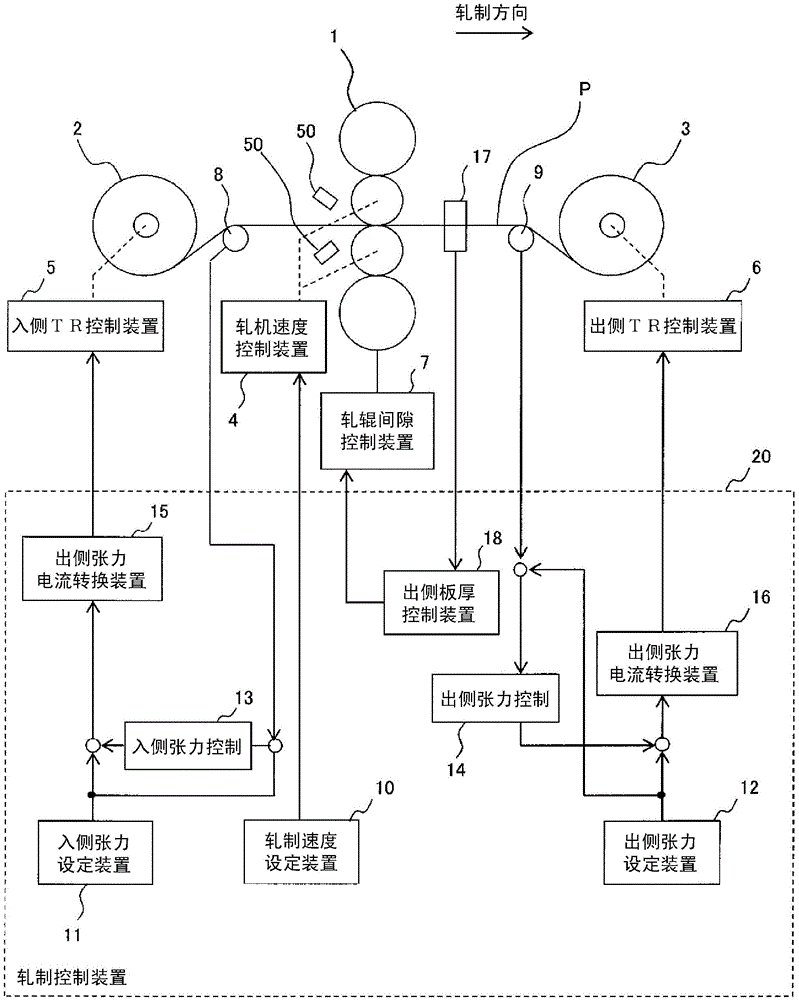

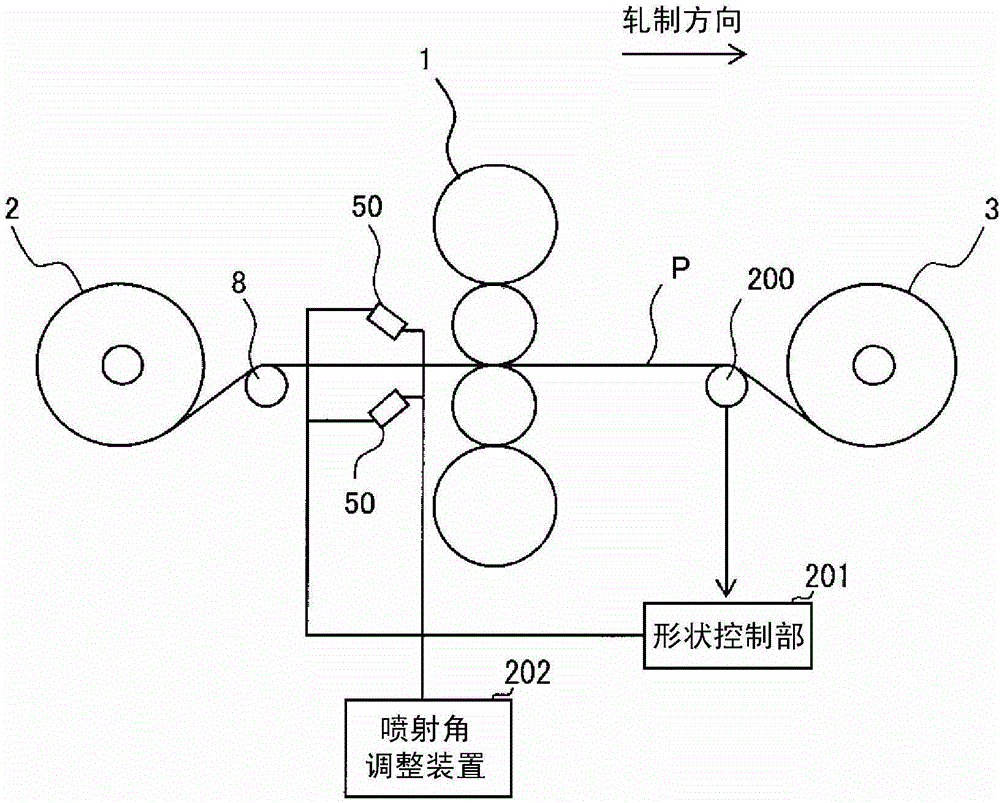

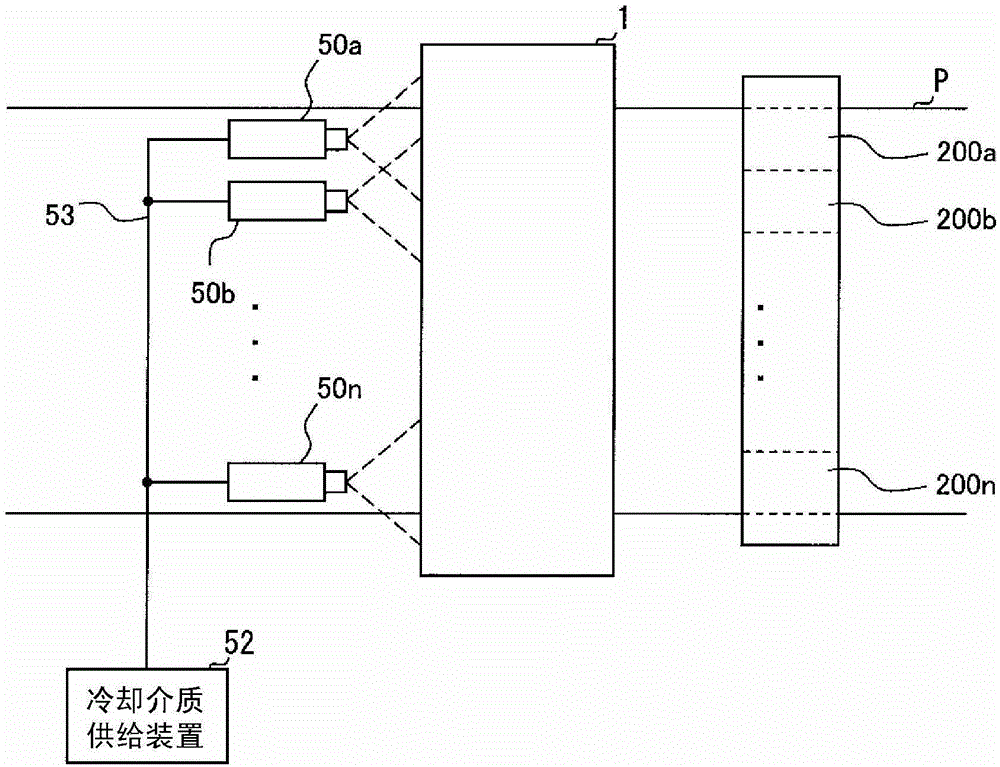

[0040] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. In this embodiment, a case where the present invention is applied to a single-stand rolling mill will be described as an example. figure 1 Indicates the configuration of a single-stand rolling mill. With respect to the rolling direction of the roll 1, the single-stand rolling mill has an entry side TR (abbreviated as the tension roller TR) 2 on the entry side, and an exit side TR3 on the exit side. The rolling is carried out by a pair of rolls from After rolling the to-be-rolled material unwound by entry-side TR2, it is performed by coiling the to-be-rolled material by exit-side TR3.

[0041] Connected to the roll 1 are a roll gap control device 7 for controlling the thickness of the material P to be rolled by changing the roll gap, and a mill speed control device 4 for controlling the rotational speed of the roll 1 . The entry-side TR2 and the exit-side TR3 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com