Rotary scanning mechanical device, three-dimensional ultrasonic imaging system and method

A technology of rotating scanning and mechanical devices, which is applied in the directions of ultrasonic/sonic/infrasonic equipment control, ultrasonic/sonic/infrasonic diagnosis, and sound wave diagnosis. and other issues to achieve the effect of improving safety and accuracy, ensuring imaging quality, and high degree of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

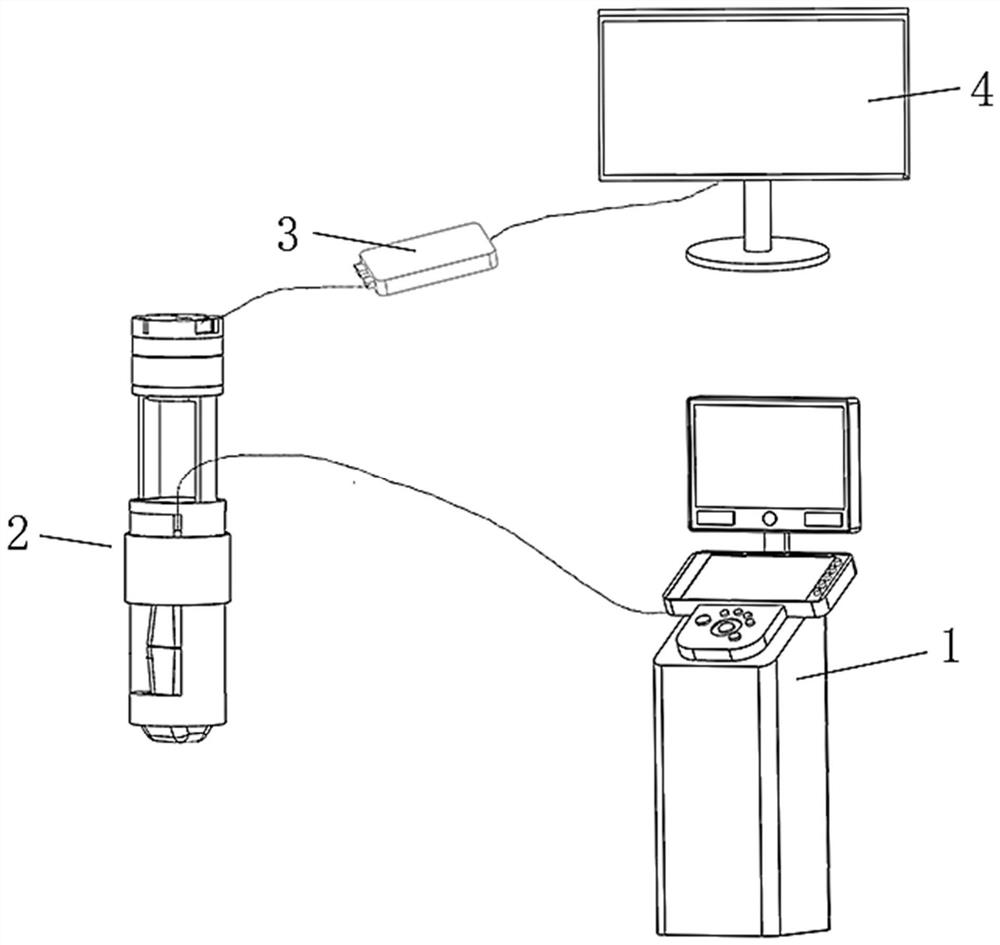

[0048] see figure 1 , the three-dimensional ultrasonic imaging system proposed by the present invention includes a rotating scanning mechanism 2 and a signal transmission and processing module 3, an ultrasonic imaging device 1 and a host computer 4, as shown in Fig. 4(a), Fig. 4(b), Fig. 4(c ), as shown in Fig. 4(d) and Fig. 4(e), the rotary scanning mechanical device 2 of the present invention includes a clamp 21, the inside of the clamp 21 is provided with an inner cavity for installing the ultrasonic probe 23, and the wall surface of the inner cavity is processed with steps Groove, the ultrasonic probe 23 is installed in the inner cavity and is limited by the stepped groove. The detection end of the ultrasonic probe 23 is exposed from the bottom of the fixture 21. The top of the fixture 21 is connected to the circular servo motor 20. The ul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com