Printing ink filtering device

A filter device and ink technology, applied in the direction of filtration and separation, fixed filter elements, chemical instruments and methods, etc., can solve problems such as inability to realize automatic cleaning, complex structure of the device, and influence on popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

[0028] This embodiment takes double filter cartridges as an example for illustration.

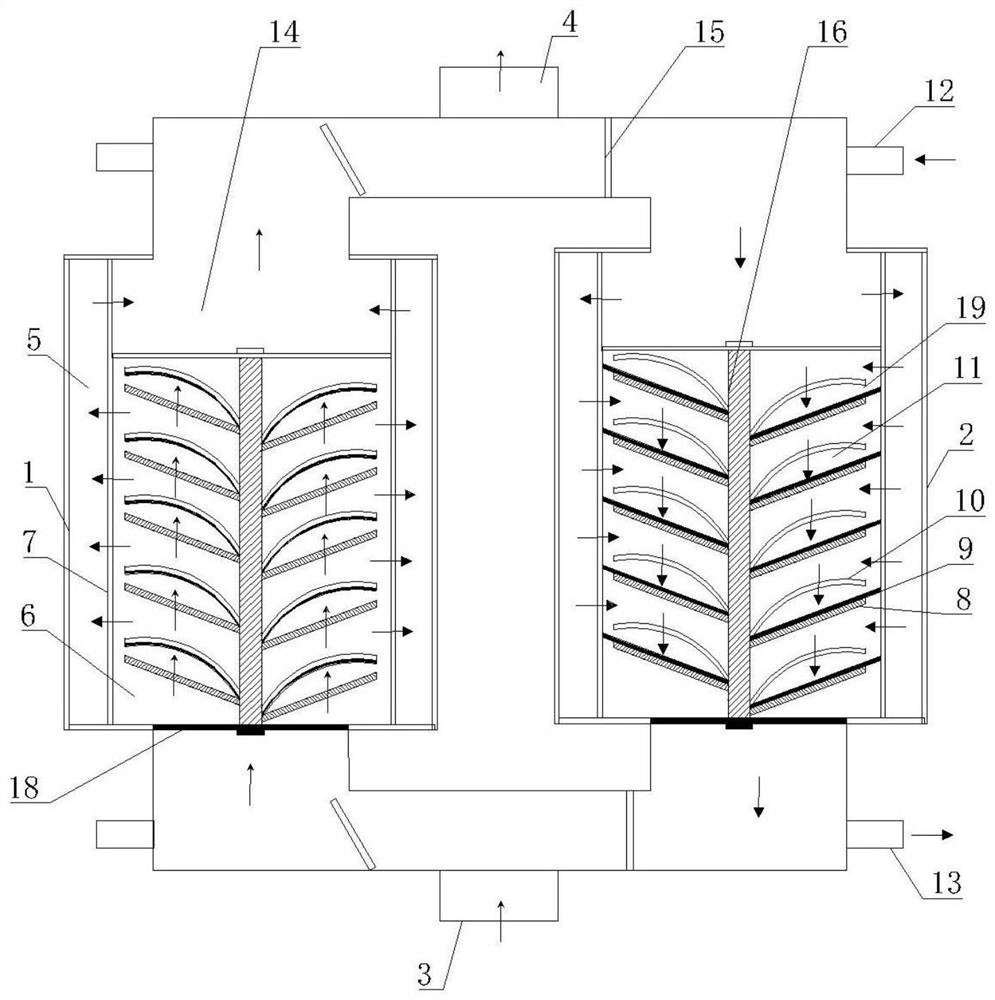

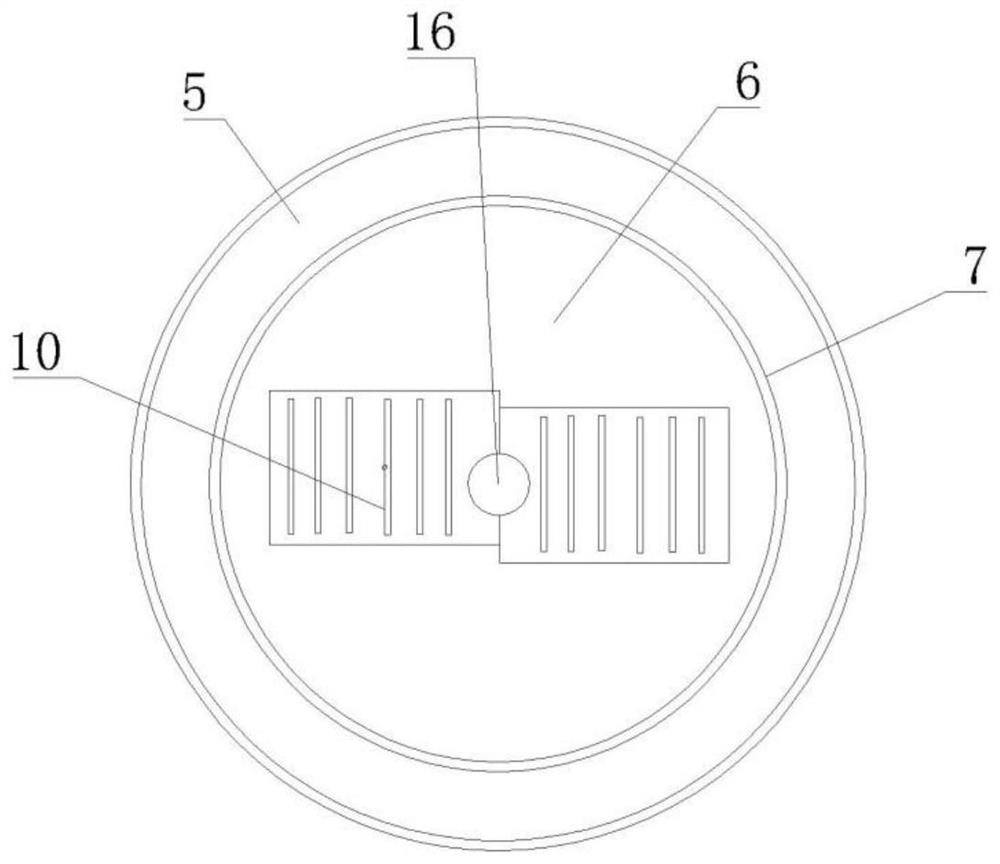

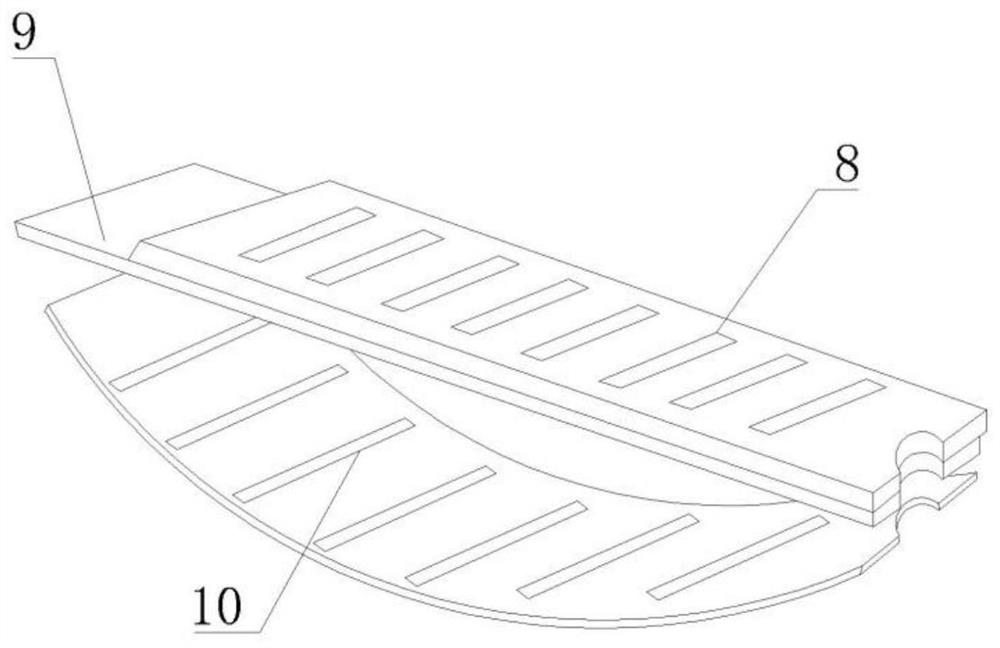

[0029] Such as Figure 1 to Figure 5 shown.

[0030] The ink filtering device includes a filter cartridge, an ink inlet pipe 3 and an ink outlet pipe 4. An outer ink chamber 5 and an inner ink chamber 6 are concentrically arranged inside the filter cartridge, and the outer ink chamber 5 and the inner ink chamber 6 are communicated through a cylindrical screen 7 , the outer ink chamber 5 is connected to the ink outlet pipe 4 , and the inner ink chamber 6 is connected to the ink inlet pipe 3 . Ink enters from the ink inlet pipe 3, flows out from the ink outlet pipe 4 after passing through the inner ink chamber 6 and the outer ink chamber 5 in sequence.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gap width | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com