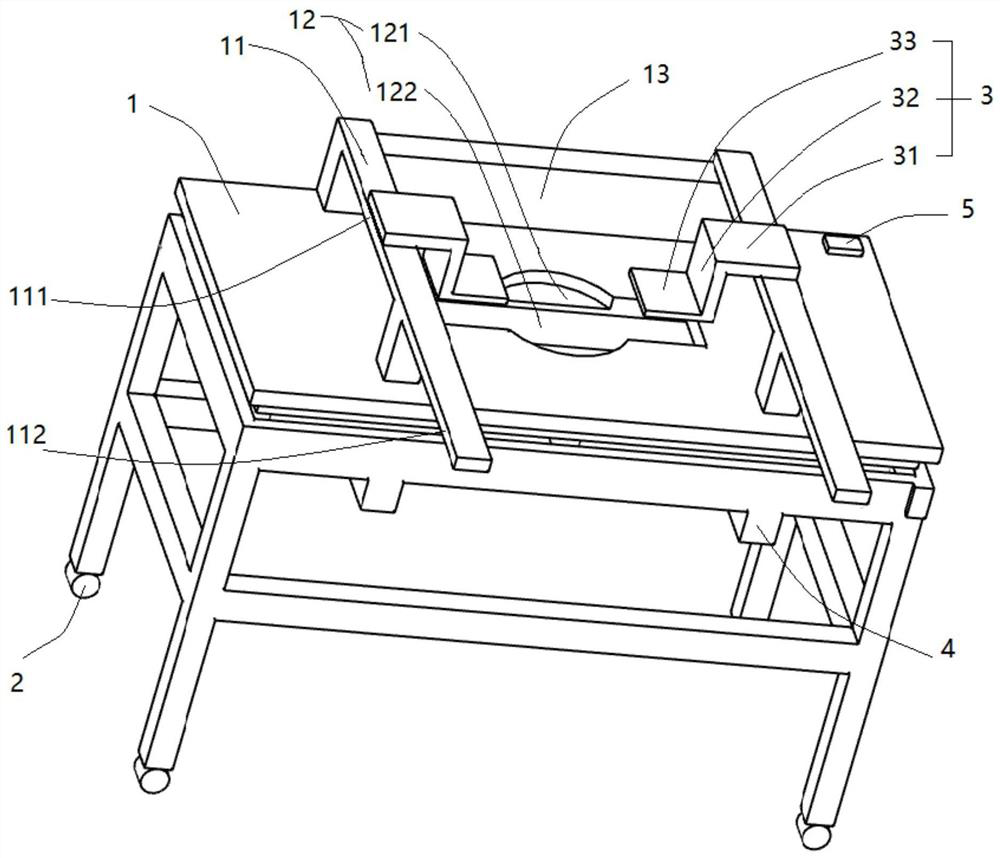

Material assembling vehicle

A technology for assembling vehicles and materials. It is used in transportation and packaging, mechanical conveyors, conveyors, etc., and can solve problems such as human injury, manual misoperation, and unfavorable structural stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

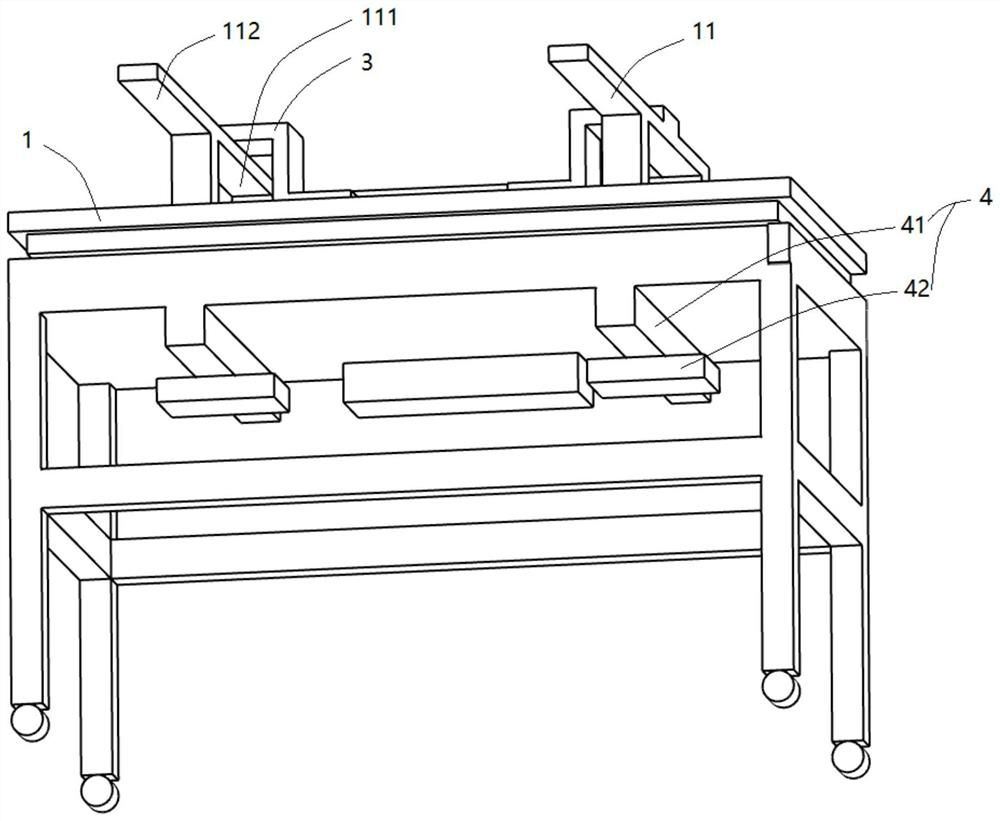

[0042] Implementation mode one: if figure 2 As shown, the driving element is a synchronous belt, the first sliding track 41 is formed on the synchronous belt, and is slidably and fixedly connected to the synchronous belt.

[0043] In this embodiment, the timing belt is connected to the motor, and the motor drives the timing belt to rotate. The slider 42 is fixedly connected to the timing belt, and the slider 42 is driven by the rotation of the timing belt. When 111 moves to the feeding end 112, the motor rotates forward and drives the synchronous belt to rotate, and drives the slider 42 to move in the opposite direction to the lifting mechanism 3, so that the center of gravity of the material platform 1 is stably placed on the material platform 1 along the material feeding The position of the center line in the given direction, when the lifting mechanism 3 moves from the feeding end 112 to the starting end 111, the motor reverses to drive the synchronous belt to rotate in the...

Embodiment approach 2

[0044] Embodiment 2: The driving member includes a cylinder connected to the motor and a push rod driven by the cylinder. The first sliding track 41 is formed on the surface of the material platform 1 , and the push rod can push the slider 42 to move relative to the first sliding track 41 .

[0045] In this embodiment, the cylinder is connected to the motor, and the push rod of the cylinder is connected to the slider 42 and can push the slider 42 to move along the first sliding track 41. When the lifting mechanism 3 moves from the starting end 111 of the extension arm 11 to the feeding end 112 At this time, the push rod pushes the slider 42 forward, and the pushing direction is opposite to the moving direction of the lifting mechanism 3, so as to stabilize the center of gravity on the centerline position of the material platform 1 along the material feeding direction. When the lifting mechanism 3 moves from the feeding end 112 to When the starting end 111 moves, the retraction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com