Constructional column structure and pouring method

A technology for constructing columns and pouring pipes, which is applied in building structures, buildings, building components, etc., can solve problems such as cracks, troublesome construction procedures, and secondary damage to structural columns.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

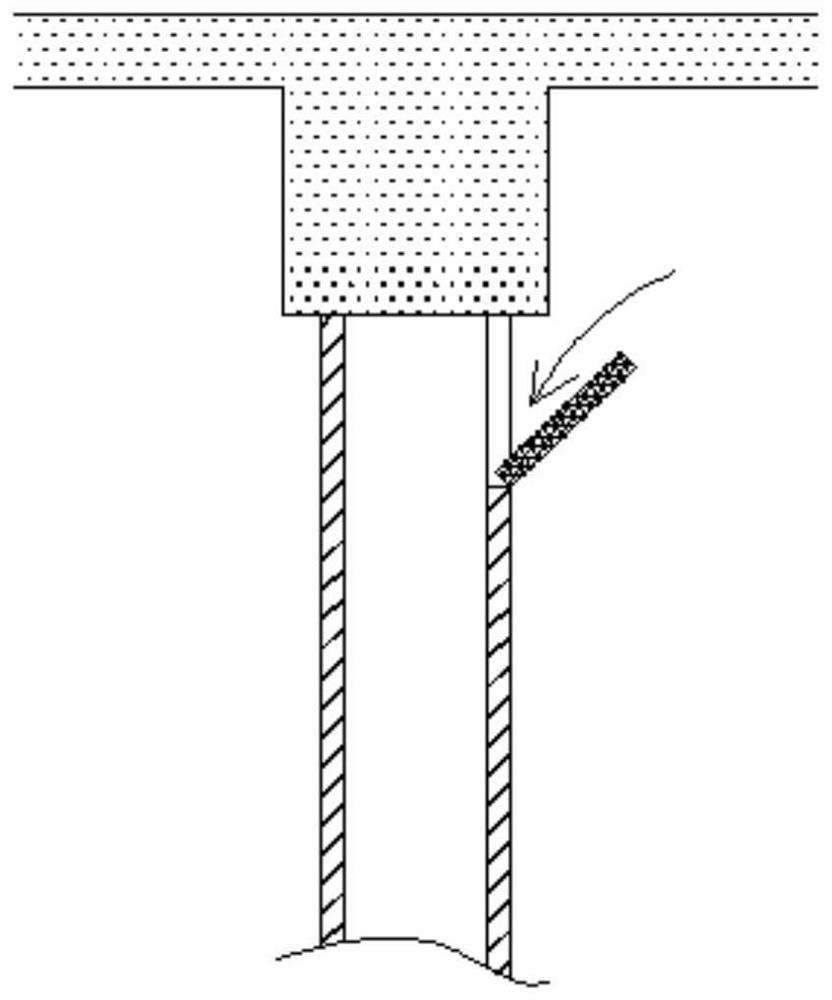

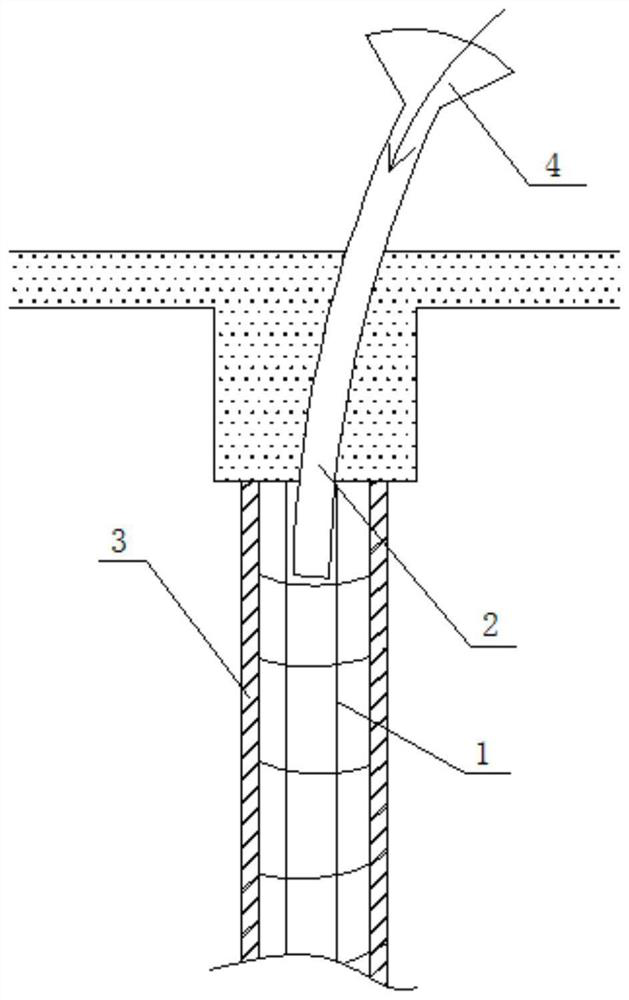

[0023] refer to Figure 1 to Figure 2 The specific implementation of a structural column structure and pouring method of the present invention will be further described.

[0024] A construction column 1 structure includes a column body composed of several steel bars and stirrups, a pouring formwork 3 is arranged on the outside of the column body, and a pouring pipe 2 is arranged on the top of the column body.

[0025] The hollow pouring pipe 2 is set on the top of the structural column 1, pre-buried in the upper beam and the upper end is exposed to the beam. The shape of the pouring pipe 2 can be set according to the density of the steel bars in the structural column 1. Generally, the diameter is set to 50- 80mm, if the steel bars are too dense, the pouring pipe 2 can be set as a flat shape, which is convenient for extending into the column. During construction, the pouring liquid can be poured directly from the upper pouring pipe 2. The construction column 1 of the present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com