Vertical storage tank facade anticorrosion derusting auxiliary device

A technology of vertical storage tanks and auxiliary devices, which is applied in the direction of building structure support, building structure support, building structure support scaffolding, etc., which can solve the problems of slow construction period, great influence of environmental conditions, and high cost of erecting scaffolding, and meet the construction period Fast, less impact on the surrounding environment, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the present invention will be further elaborated below in conjunction with specific drawings.

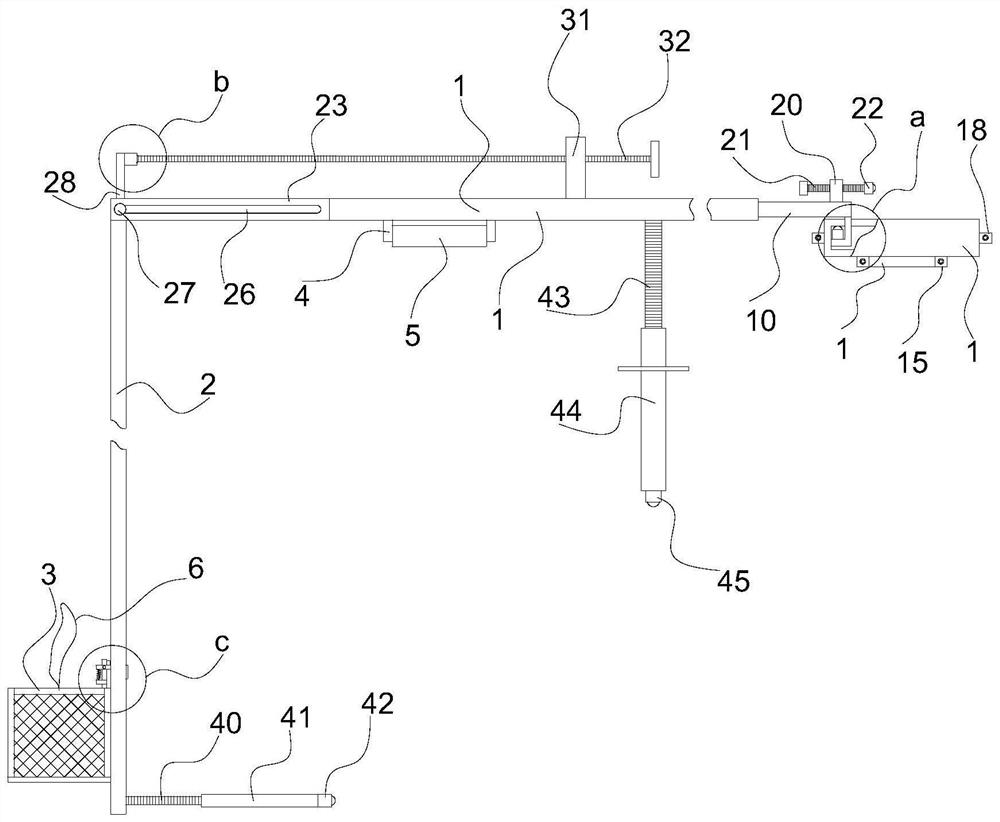

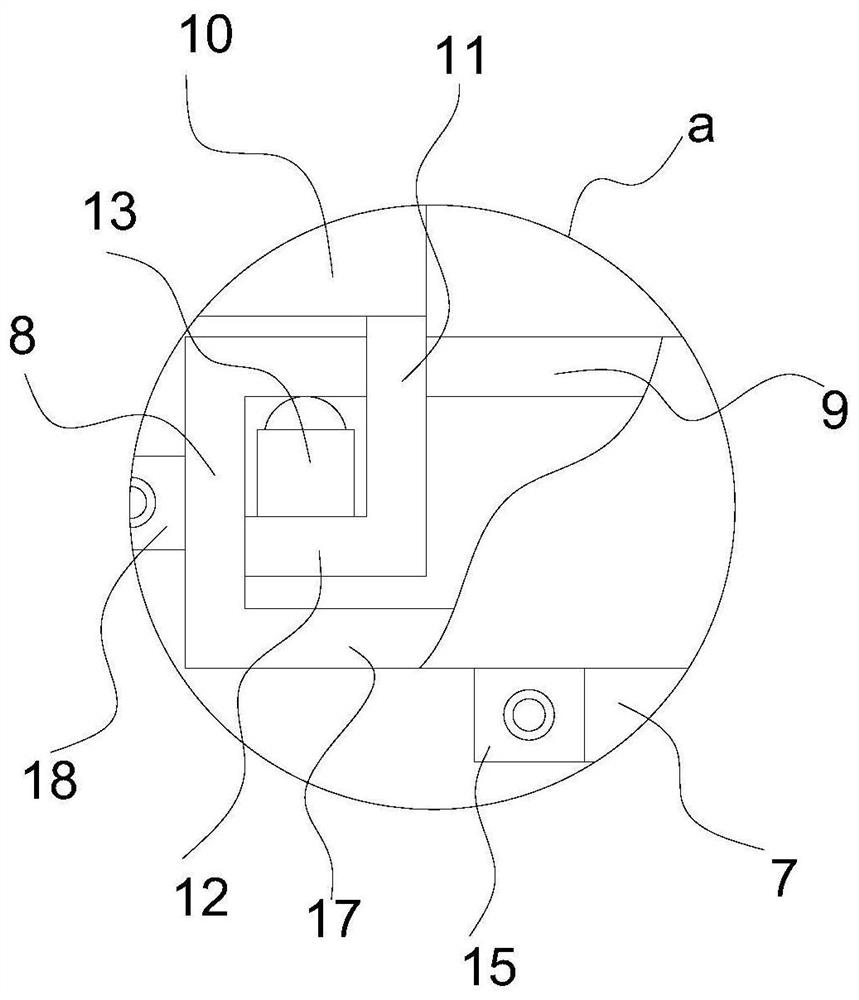

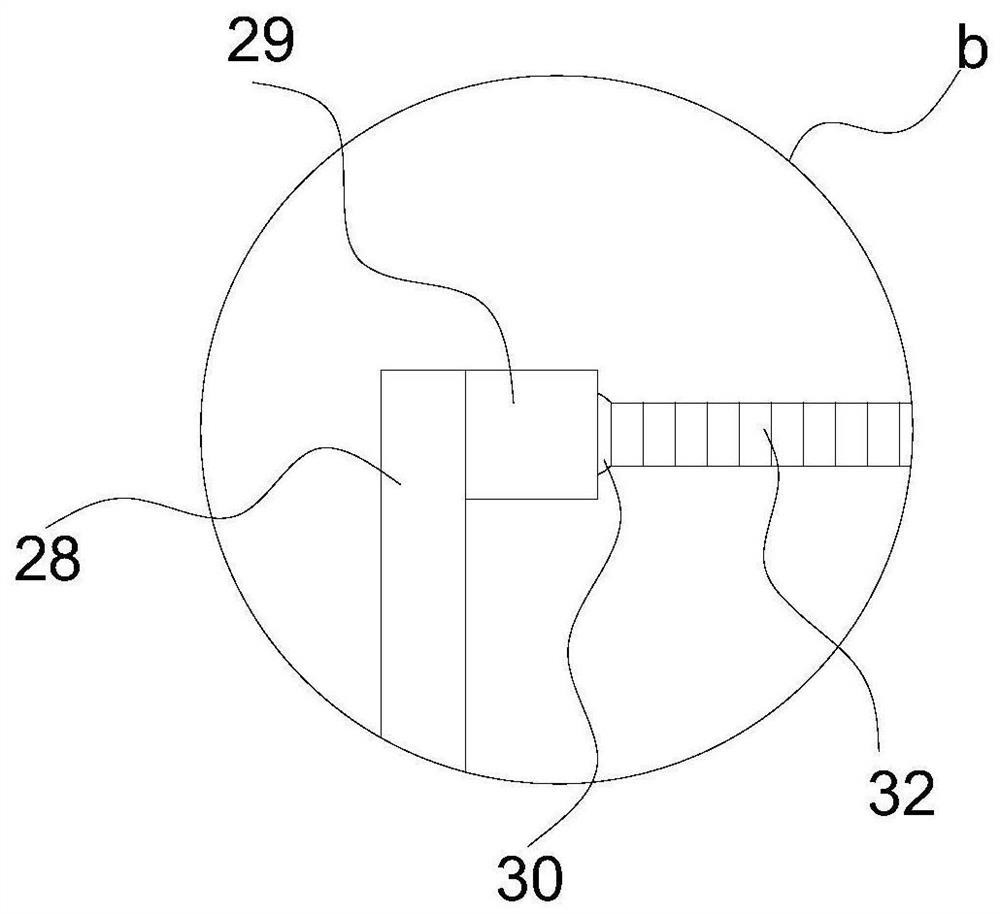

[0028] Such as figure 1 and Figure 5 As shown, the present invention includes a fixed part, a support plate 1, a ladder 2 and an accommodating basket 3, the fixed part is used to be fixed on the short flange pipe on the top of the vertical storage tank, and the first end of the support plate 1 is rotatably connected to the The fixed part, so that the support plate 1 can make a circular motion with the axis line of the short flange pipe on the top of the vertical storage tank as the rotation axis. The lower side of the support plate 1 is rotatably provided with a drum 5, and the drum 5 Both ends of the shaft are provided with rotating support plates 4, bearings are provided on the rotating support plates 4, shaft rods are arranged inside the drum 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com