Oil receiving structure of fluid loading and unloading device

A loading and unloading device and fluid technology, which is applied in the direction of adjustable connection, sleeve/socket connection, pipe/pipe joint/pipe fitting, etc. It can solve problems such as unsafety, oil pipe descending distance from guide rod, long power source, potential safety hazards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

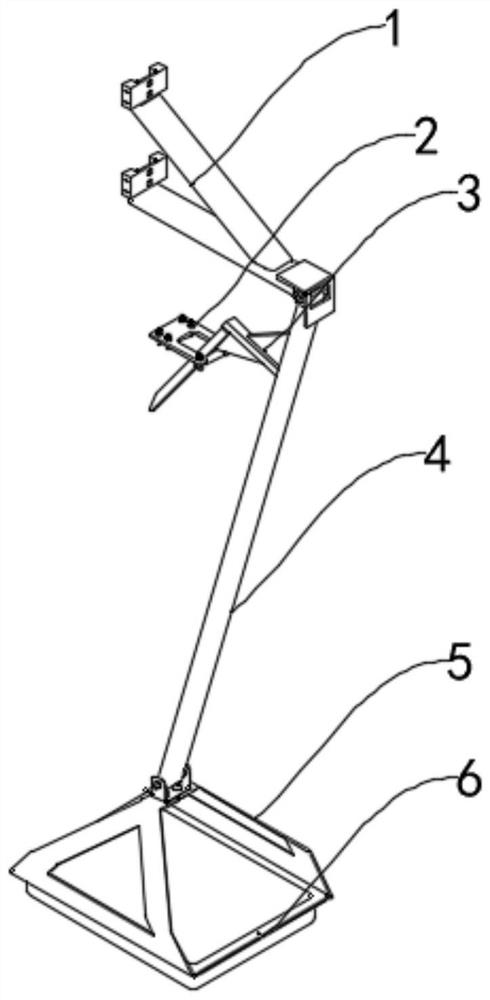

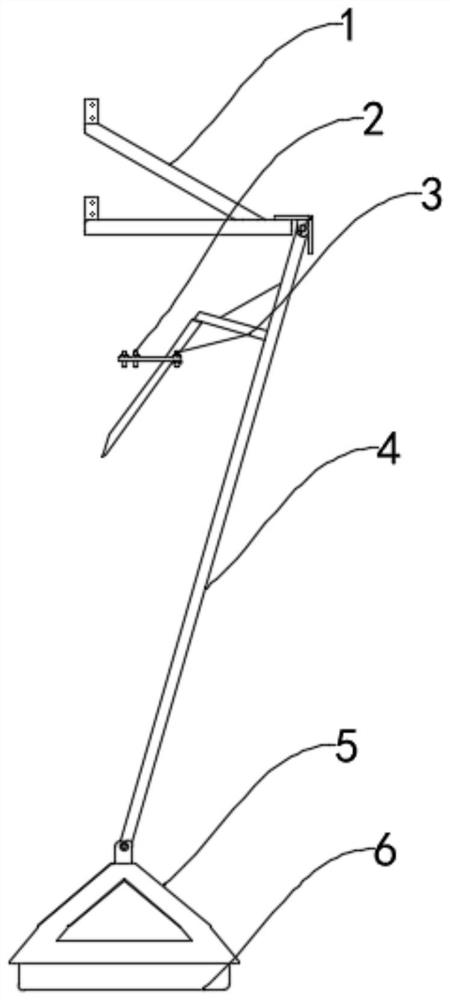

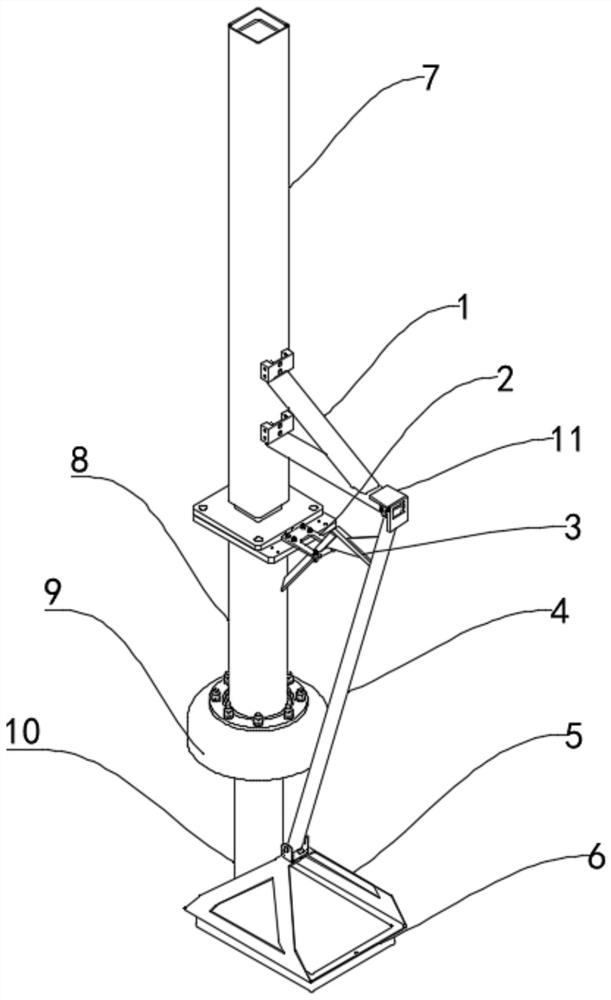

[0034] Such as Figure 1-2 As shown, the present embodiment provides the oil receiving structure of the fluid loading and unloading device, including a fixed frame 1 and an oil receiving pan 6, and the oil receiving pan 6 is connected to the fixed frame 1 by rotating the turret 4, and the turret 4 is specifically connected through the connecting frame 4. The oil support 5 is connected to the oil receiving pan 6, so that the oil receiving pan 6 will not turn over during the movement, and the operation is stable. A liftable oil outlet pipe is provided below the fixed frame 1, and a transmission structure is provided between the oil outlet pipe and the turret 4. During the rising process of the oil outlet pipe, the oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com