Gas turbine combustor capable of achieving diffusion and premixed combustion dual-mode switching

A gas turbine, premixed combustion technology, used in combustion chambers, combustion methods, combustion equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

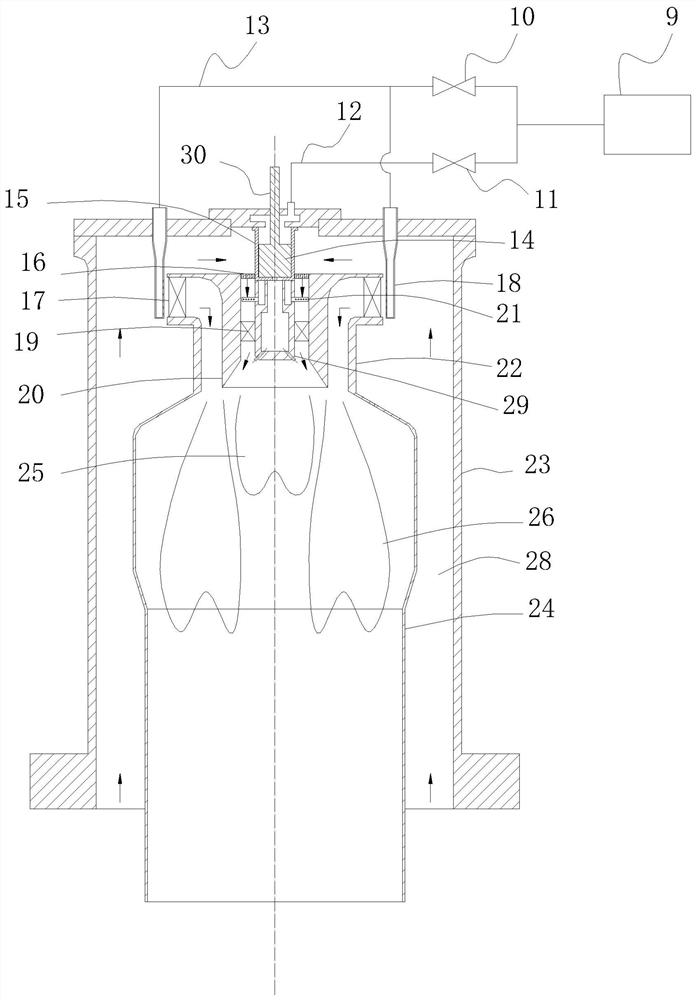

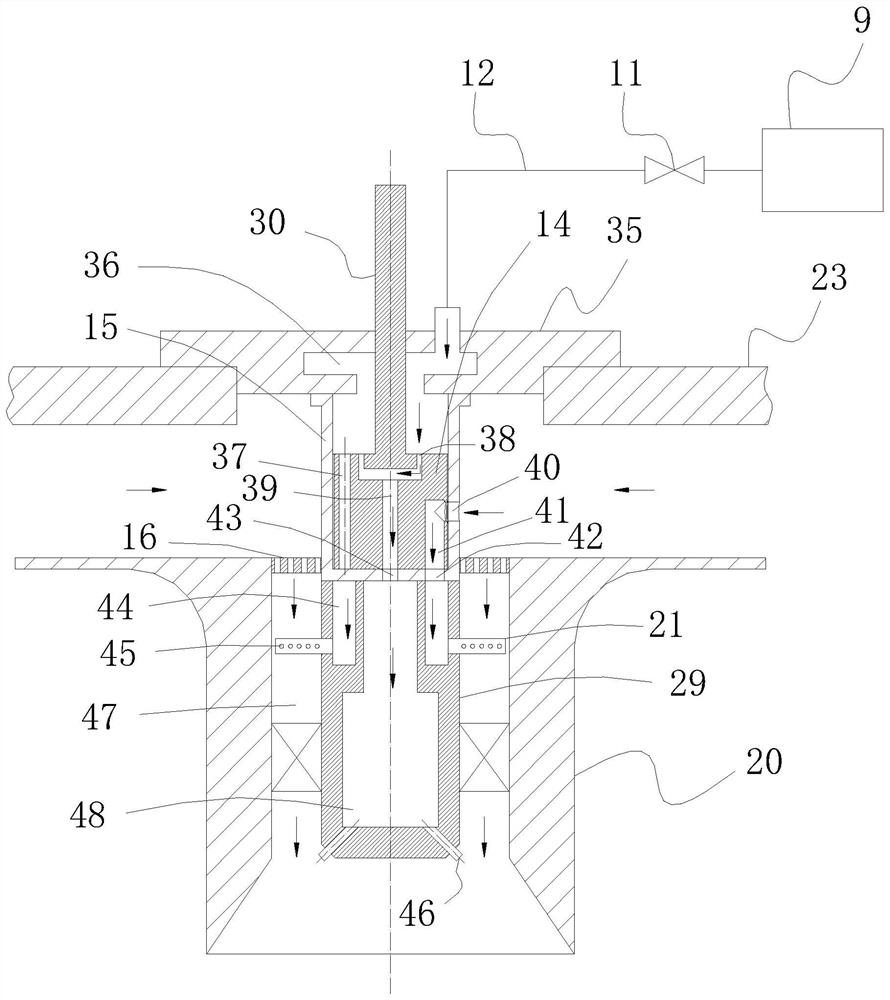

[0029] see Figure 1-8, a gas turbine combustor capable of dual-mode conversion of diffusion and premixed combustion, including a housing 23 and a fuel supply source 9, the upper end of the housing 23 is circumferentially symmetrically connected with a main fuel nozzle 18, and the upper end of the main fuel nozzle 18 passes through the main fuel pipeline 13 is connected to the fuel supply source 9, the input end of the duty fuel chamber 36 is connected to the fuel supply source 9 through the duty fuel pipeline 12, and the main fuel regulating valve 10 is respectively installed on the main fuel pipeline 13 and the duty fuel pipeline 12 and the on-duty fuel regulating valve 11, the fuel from the fuel supply source 9 is sent into the burner for combustion through the main fuel regulating valve 10, the duty fuel regulating valve 11, the main fuel pipeline 13 and the duty fuel pipeline 12 respectively, and the main fuel nozzle 18 The upper end is connected with a fuel supply source...

Embodiment 2

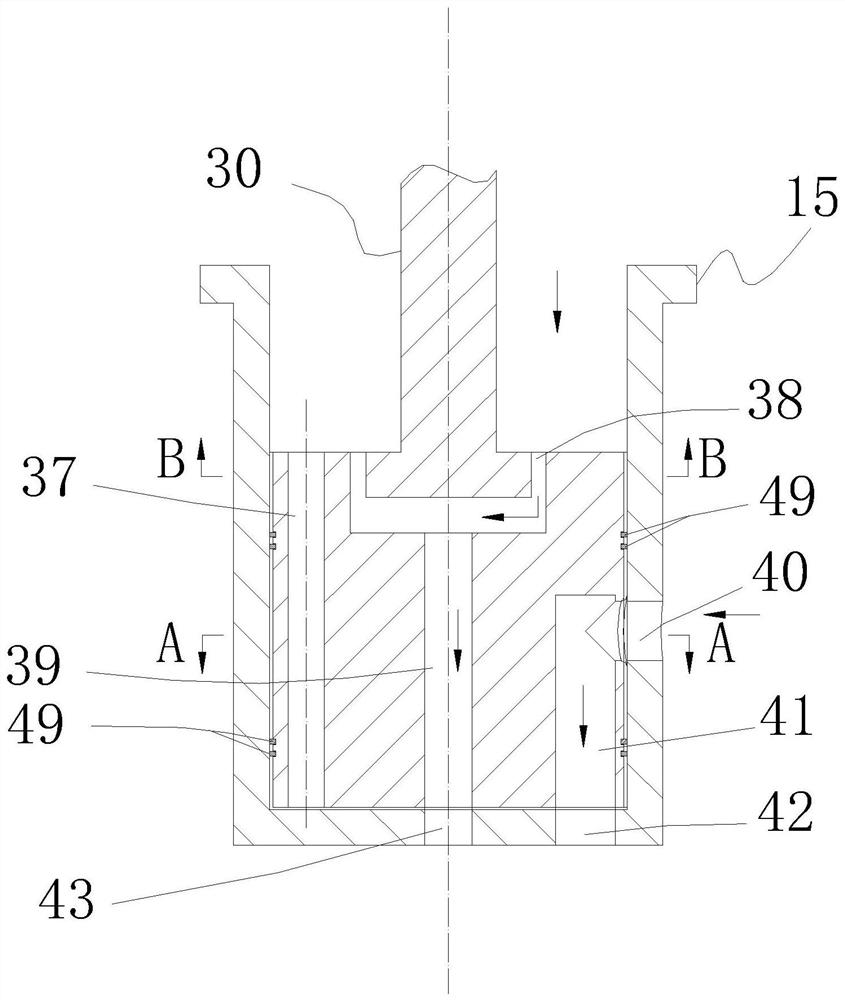

[0032] see Figure 9-12 , in this embodiment, the core body 14 of the adjustable conversion device is provided with a core body diffused fuel channel and a core body center diffused air channel, respectively replacing the core body diffused fuel channel 39 and the core body premixed fuel channel 37, correspondingly , the bottom of the adjustable conversion device housing 15 is provided with a corresponding housing center diffusion fuel outlet and a housing center diffusion air outlet, and its side is provided with a corresponding housing center diffusion air inlet.

[0033] Working process: In the full diffusion mode, the fuel enters from the on-duty fuel chamber 36 through the core diffuser fuel annular inlet 38, flows through the core diffuser fuel channel, the shell center diffuser fuel exit hole, and finally enters the corresponding diffuser nozzle 29 on duty. The diffusion injection hole chamber 48 is injected from the diffusion fuel injection hole 46 to form diffusion co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com