Device for automatically detecting compression resistance of new energy automobile battery

An automatic detection device, new energy vehicle technology, applied in the direction of measuring device, applying stable tension/pressure to test material strength, strength characteristics, etc., can solve large errors, laborious testing of compressive performance, and workload of compressive performance testing Major problems, to achieve the effect of reducing the workload of workers, improving inspection work, and reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

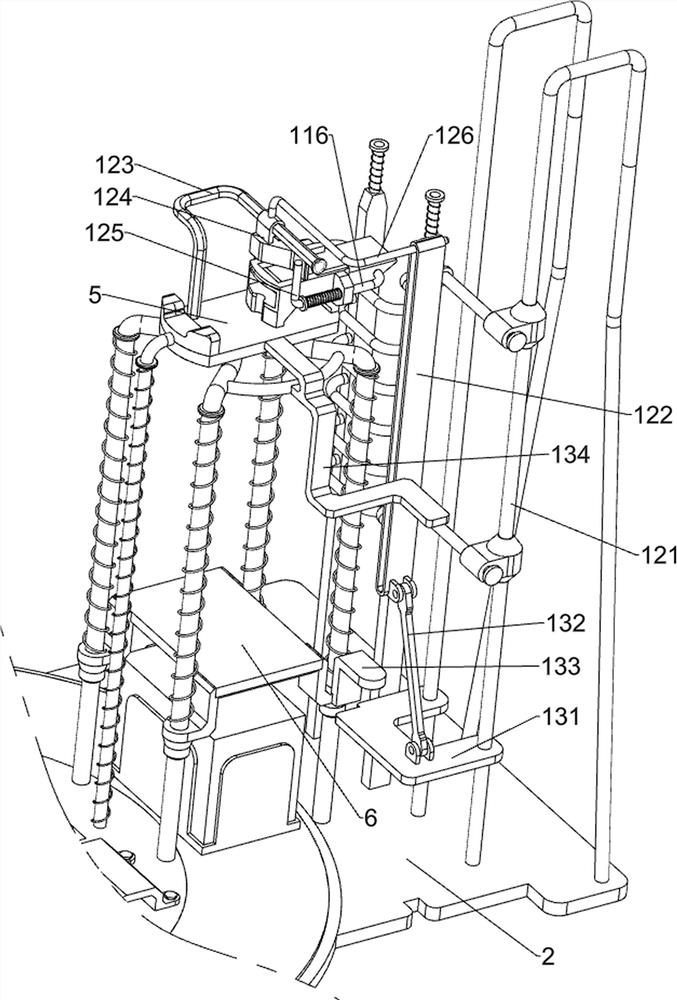

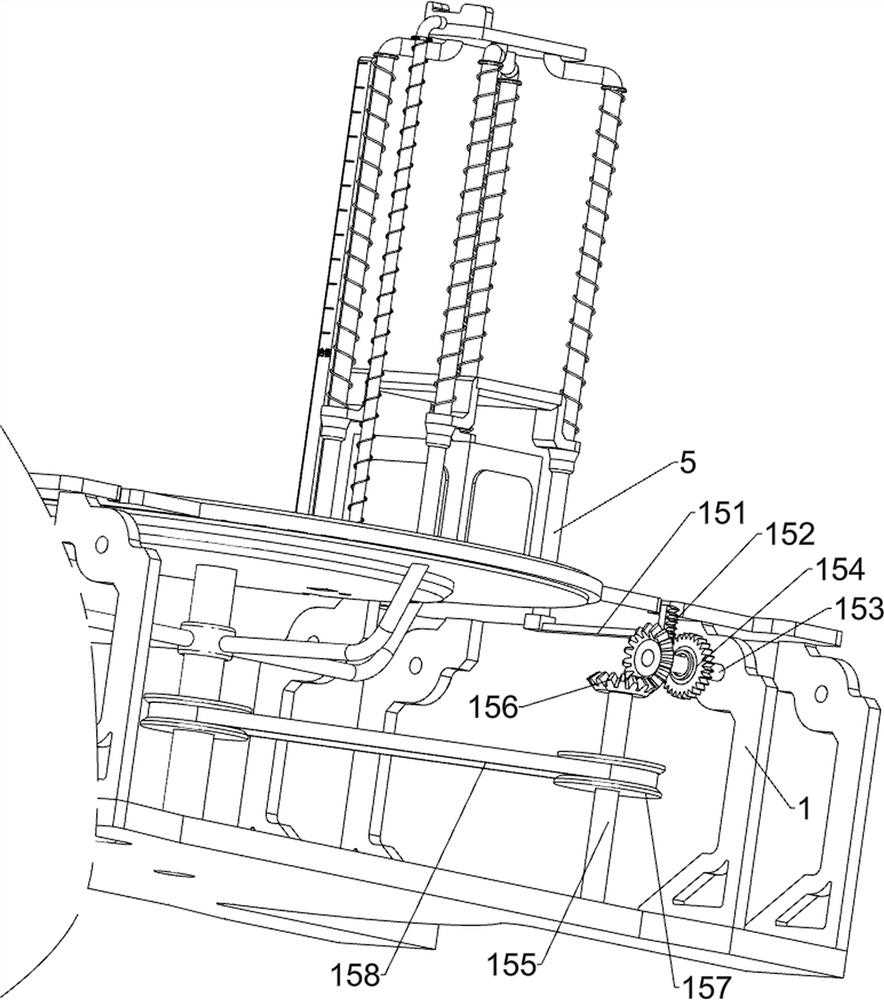

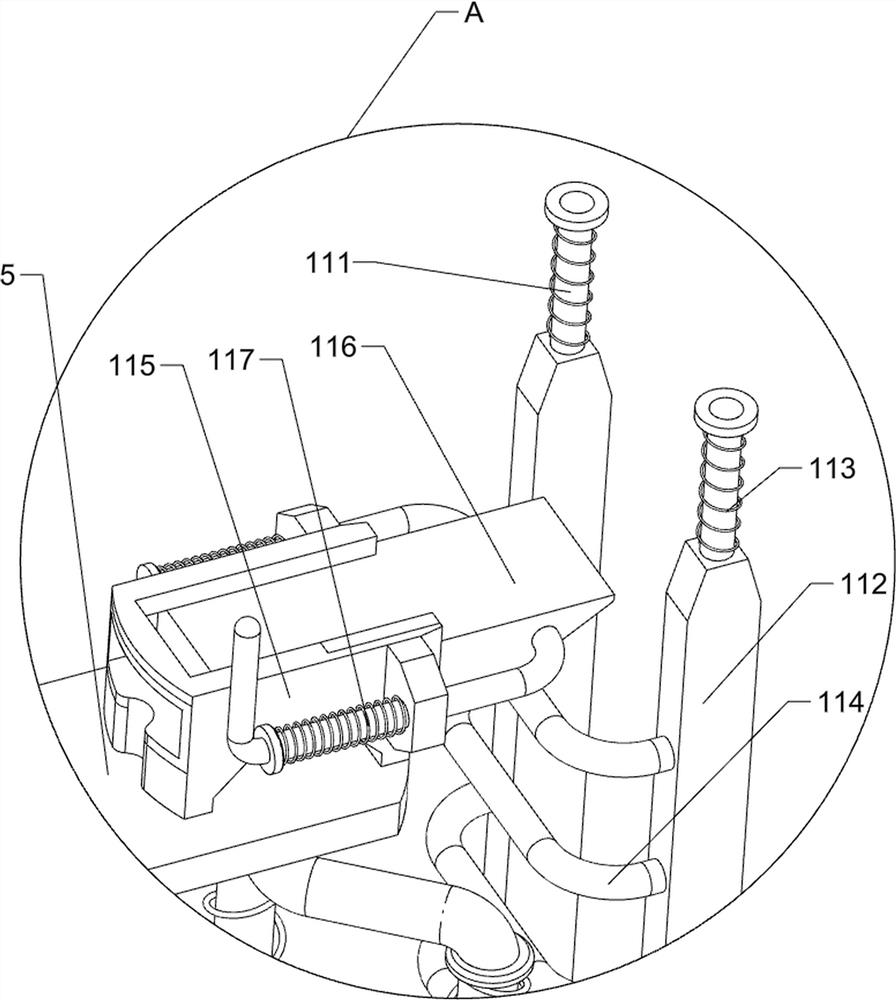

[0030] Such as Figure 1-3 As shown, the automatic detection device for the compression performance of a new energy vehicle battery of the present invention includes a first fixing frame 1, a first mounting frame 2, a shaft rod 3, a disc 4, a sliding frame 5, and a first pressing plate 6 , the first compression spring 7, the second compression spring 8, the placing assembly 9, the driving assembly 10 and the clamping assembly 11, the first mounting frame 2 is connected to the top of the first fixing frame 1, and the left lower part of the first fixing frame 1 is rotatable A shaft rod 3 is connected, the upper part of the shaft rod 3 is rotatably connected with a dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com