Horizontal groove entering machine capable of achieving secondary groove entering

A slotting machine, horizontal technology, applied in the field of slotting machines, can solve the problems of poor assembly stability and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

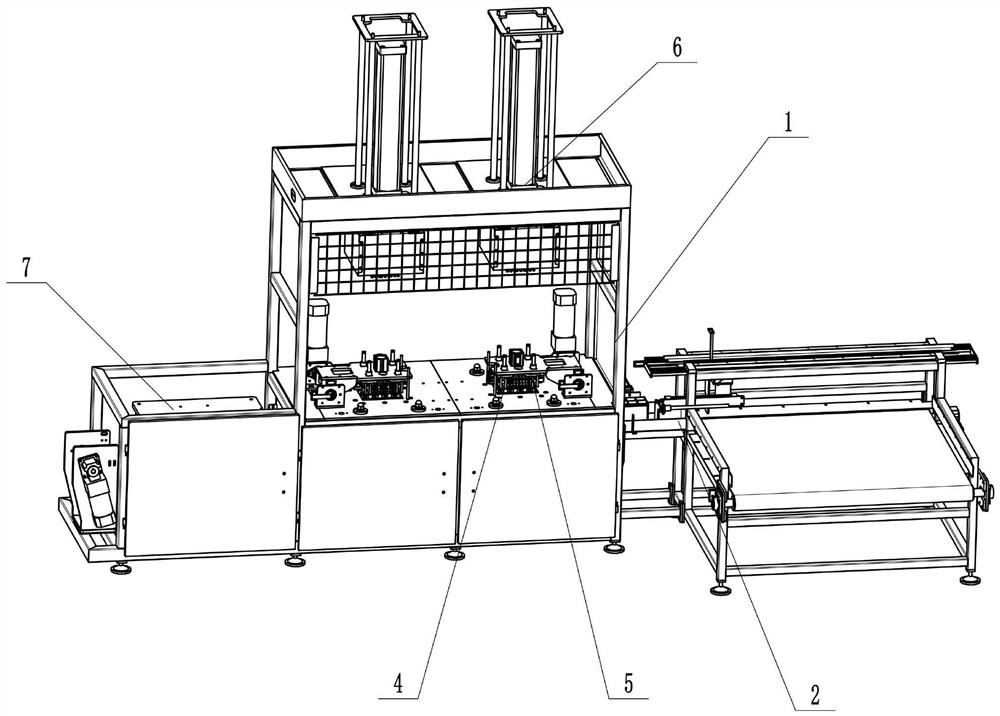

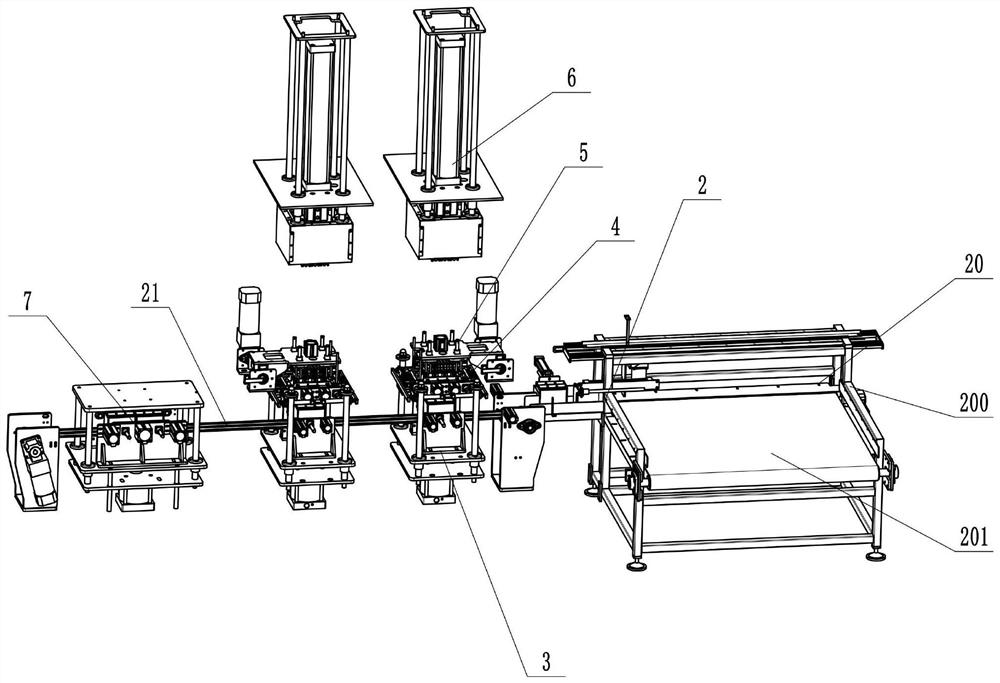

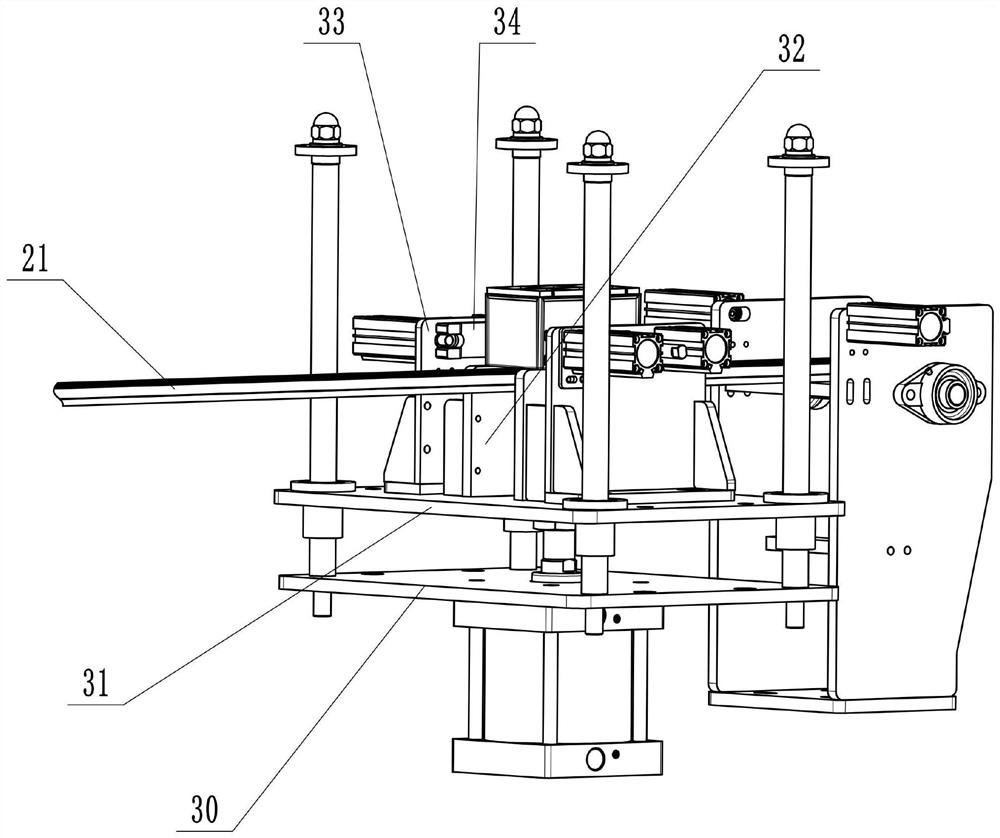

[0035] Example 1, such as figure 1 , 2 As shown, a horizontal slotting machine for secondary slotting, including a channel-type support 1, the support 1 is connected with a plastic case delivery device 2, and the left side of the plastic case delivery device 2 is provided with two top moldings. A shell device 3, a clamp device 4 is arranged above the top plastic shell device 3, the top plastic shell device 3 and the clamp device 4 are placed inside the bracket 1, and a reversible ear mechanism 5 is arranged above the clamp device 4 A punching needle mechanism 6 that can slide up and down is arranged above the ear-adjusting mechanism 5, and the ear-adjusting mechanism 5 and the punching needle mechanism 6 are connected to the bracket 1 respectively. The secondary slotting mechanism 7 for the secondary slotting, the molded case feeding device 2 runs through the top molding case device 3 and the secondary slotting mechanism 7 .

[0036] Such as figure 2 As shown, the plastic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com