Energy-saving and environment-friendly solid garbage treatment equipment

A waste disposal equipment, energy-saving and environment-friendly technology, applied in grain processing, presses, manufacturing tools, etc., can solve the problems of labor-intensive, time-consuming manual collection of solid waste, air pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

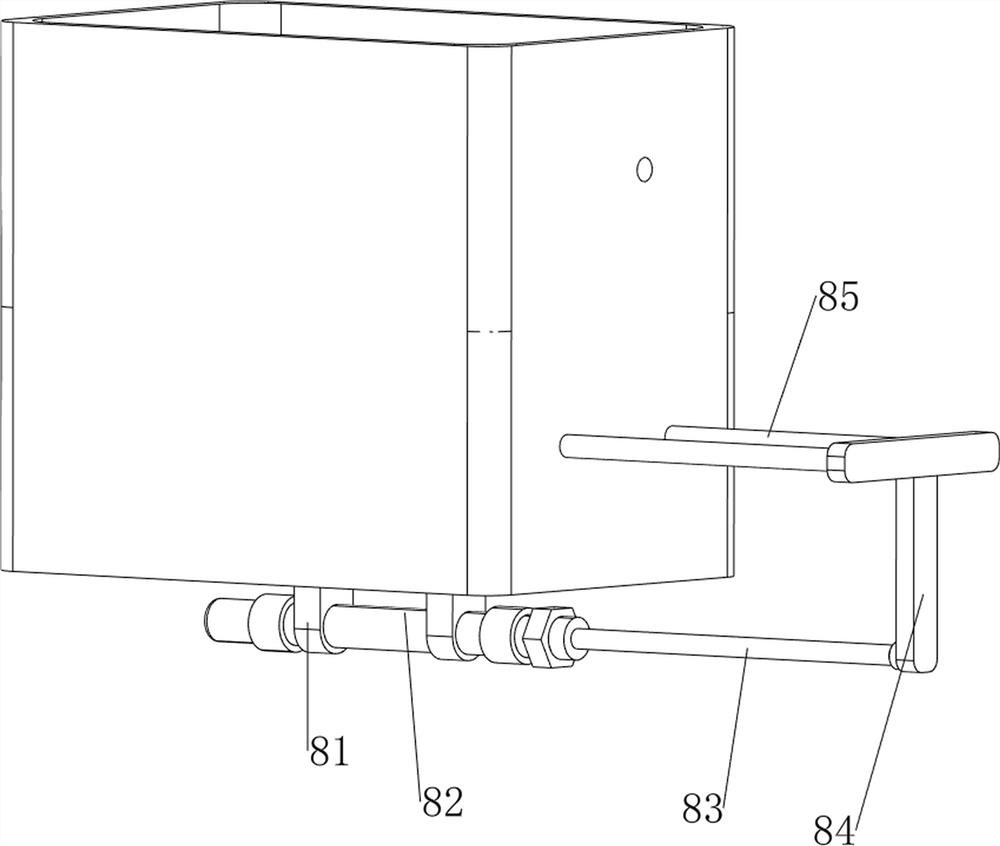

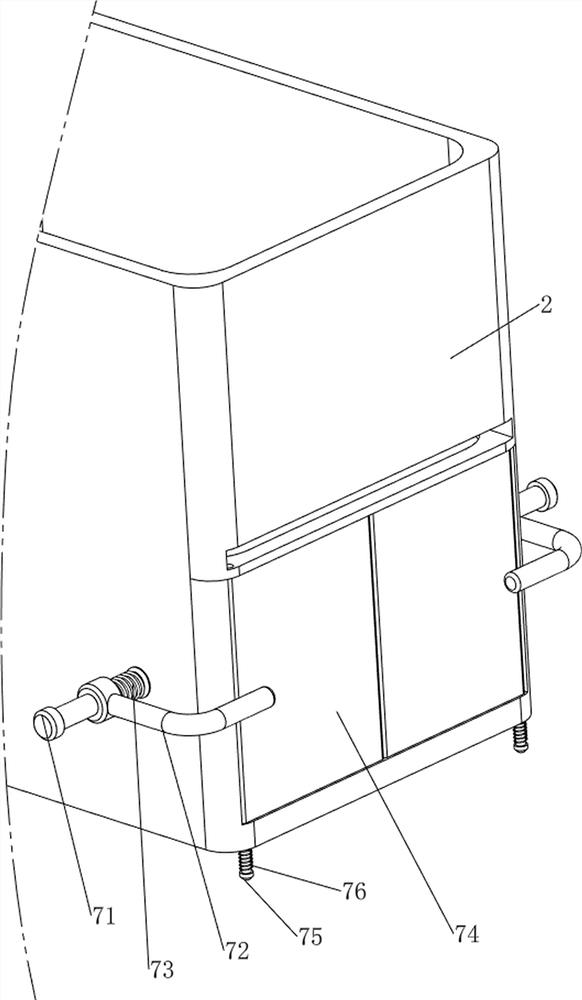

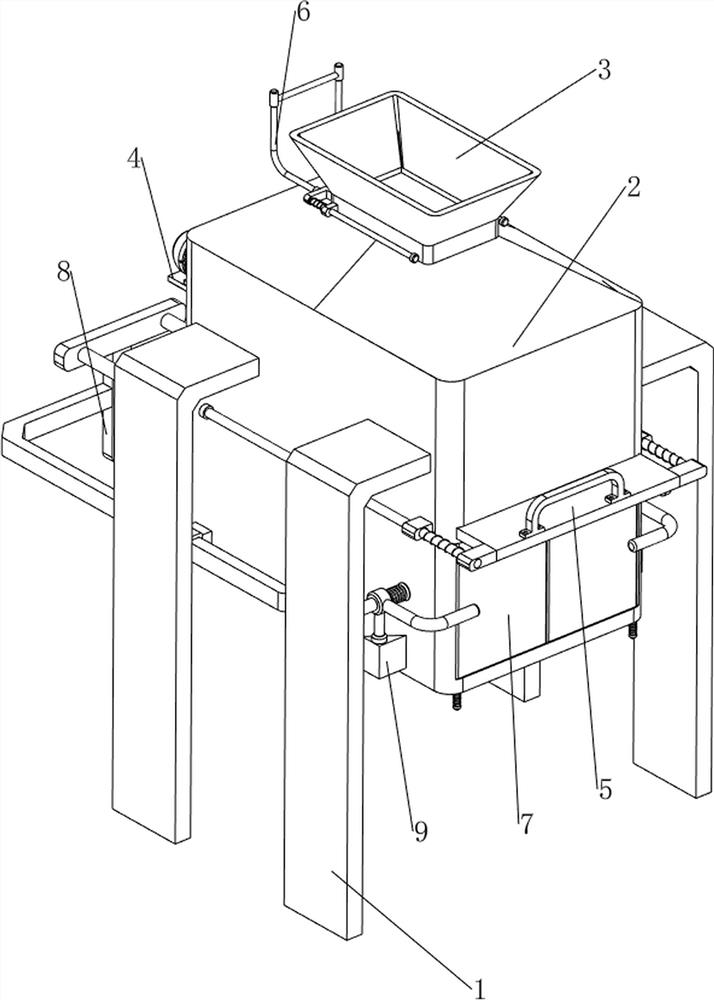

[0027] An energy-saving and environment-friendly solid waste treatment equipment, such as figure 1 As shown, it includes a support leg 1, a storage frame 2, a discharge frame 3, a crushing mechanism 4 and a material blocking mechanism 5, a storage frame 2 is connected between the tops of the support legs 1, and a discharge frame is installed through the top of the storage frame 2. A crushing mechanism 4 is connected between the frame 3 and the upper part of the inner wall of the material storage frame 2, and the middle part of the material storage frame 2 is slidingly provided with a material blocking mechanism 5.

[0028] When a worker needs to dispose of solid waste, the worker first needs to pour an appropriate amount of solid waste into the discharge frame 3, and the solid waste in the discharge frame 3 will slide into the storage frame 2, and then the worker needs to control the crushing mechanism 4 Rotation, the rotation of the crushing mechanism 4 will crush the solid w...

Embodiment 2

[0030] In a preferred embodiment of the present invention, as Figure 2-Figure 7 As shown, the crushing mechanism 4 includes a photosensitive switch 41, a support 42, a motor 43, a crushing rod 44 and a gear set 45, a photosensitive switch 41 is installed on the upper part of the inner wall of the material storage frame 2, and the upper part of the rear side of the outer wall of the material storage frame 2 is welded with Bracket 42, the top of bracket 42 is fixedly connected with motor 43 by bolts, photosensitive switch 41 is electrically connected with motor 43, and the symmetrical rotation type between the material storage frame 2 top is provided with crushing rod 44, and the left side is behind the crushing rod 44 End is connected with the output shaft front end of motor 43, and gear set 45 is connected between two smashing rods 44 rear sides.

[0031] When the photosensitive switch 41 senses the light, the photosensitive switch 41 will control the rotation of the motor 43...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com