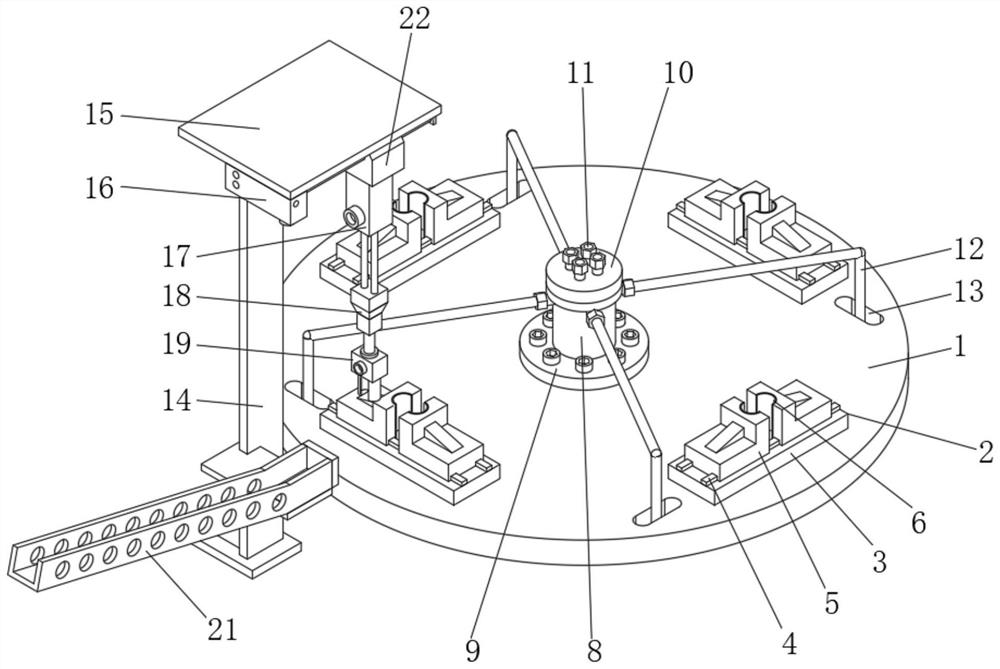

Multi-station rotating disc type bent foot upper and lower portion automatic overturning machining device

A technology for automatic turning and processing equipment, which is applied in metal processing equipment, metal processing, metal processing machinery parts, etc., and can solve problems such as inconvenient joint processing and use, joints that cannot be automatically put in, joints that cannot be clamped and fixed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the techniques, creative features, objective and efficacy of the present invention, and the embodiments are further illustrated in connection with the specific embodiments.

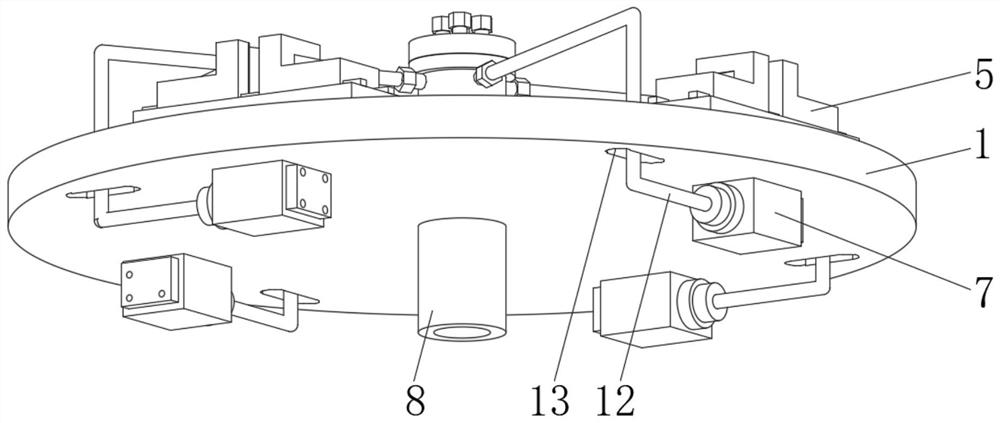

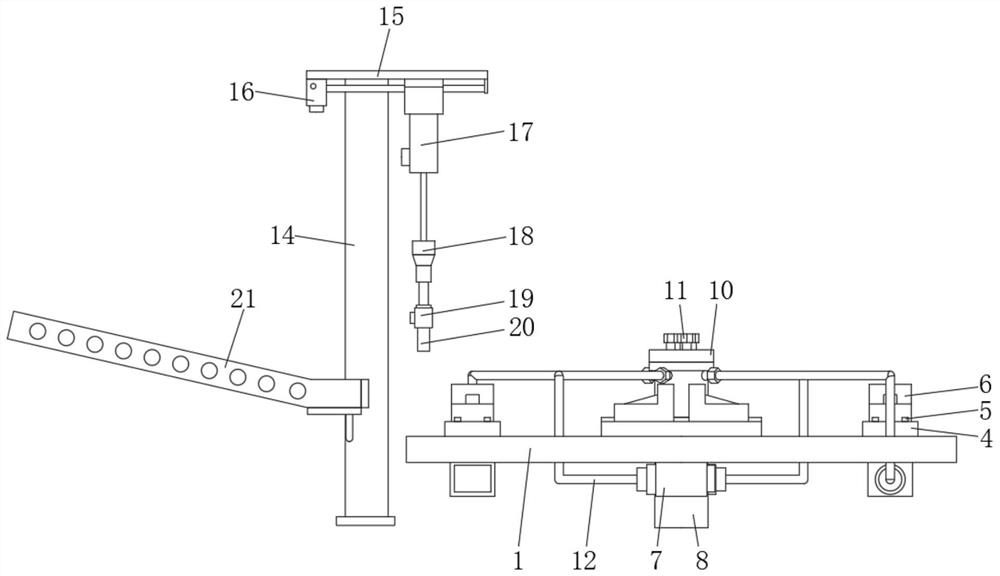

[0019] like Figure 1-3 As shown in a lower portion of the multi-position rotary bending feet automatically flip processing apparatus, comprising a rotary disk 1 and a vertical mounting plate 14, mounting plate 14 is located in vertical position in front of the rotary disk 1, the outer side of the rotary disk 1 there are four gripping mechanism 2, the rotary disk 1 is mounted intermediate movable support pillar 8, 8 fixed to the outside of the support post is attached to the mounting ring 9, the outer surface of the upper end of the support column 8 is fixed to the adapter block 10 is attached to the air, the air the upper surface of the adapter block 10 is fixedly mounted a plurality of pipe fittings 11, bottom air switching block 10 is fixedly mounted a plurality of guide pipe 12, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com