A feeding device for processing fused silica particles

A technology of fused silica and pellets, applied in loading/unloading, transportation and packaging, conveyor objects, etc., can solve the problems of reducing production quality, narrow application range, inability to adjust the height of the feeding port, etc., to achieve flexible feeding speed , The effect of adjusting the cutting speed and improving the production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

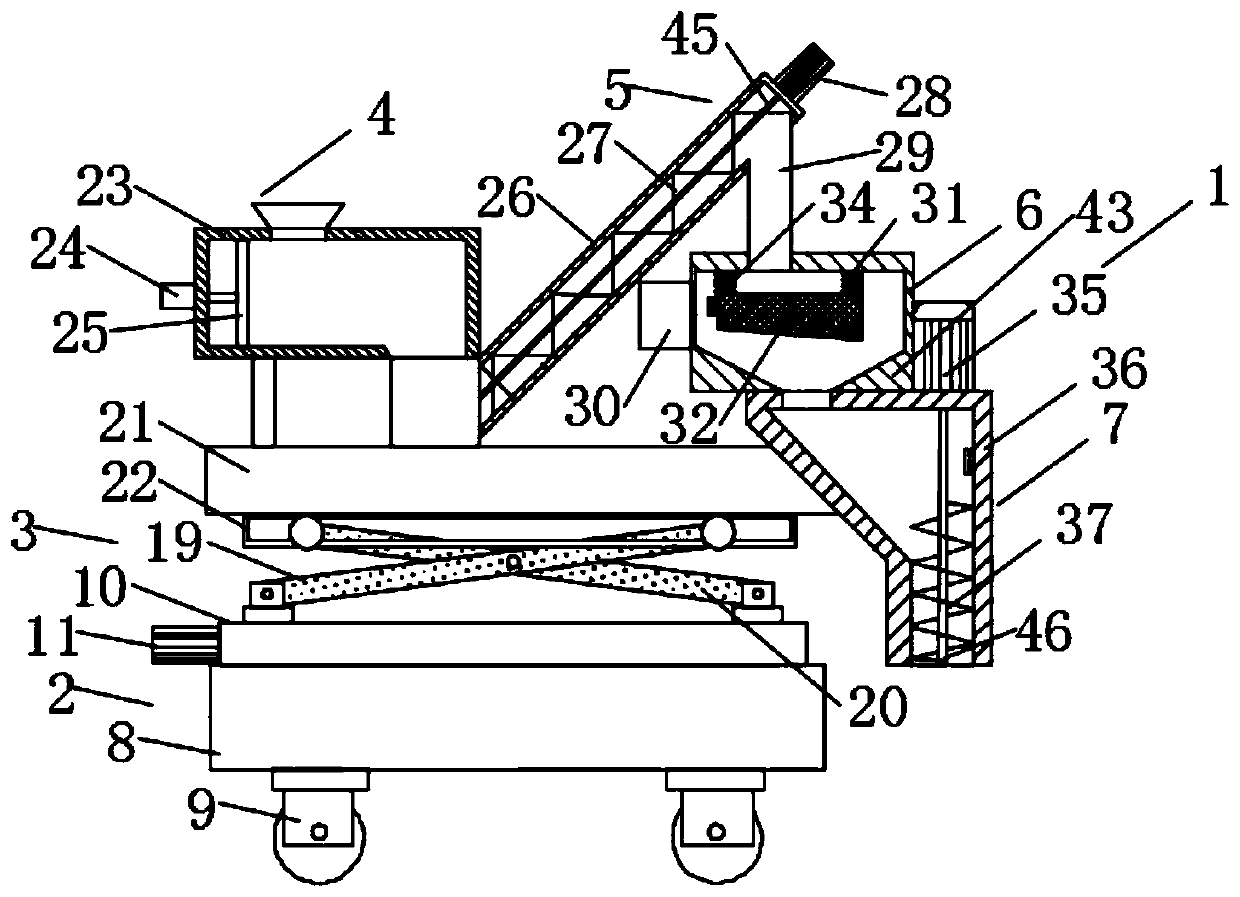

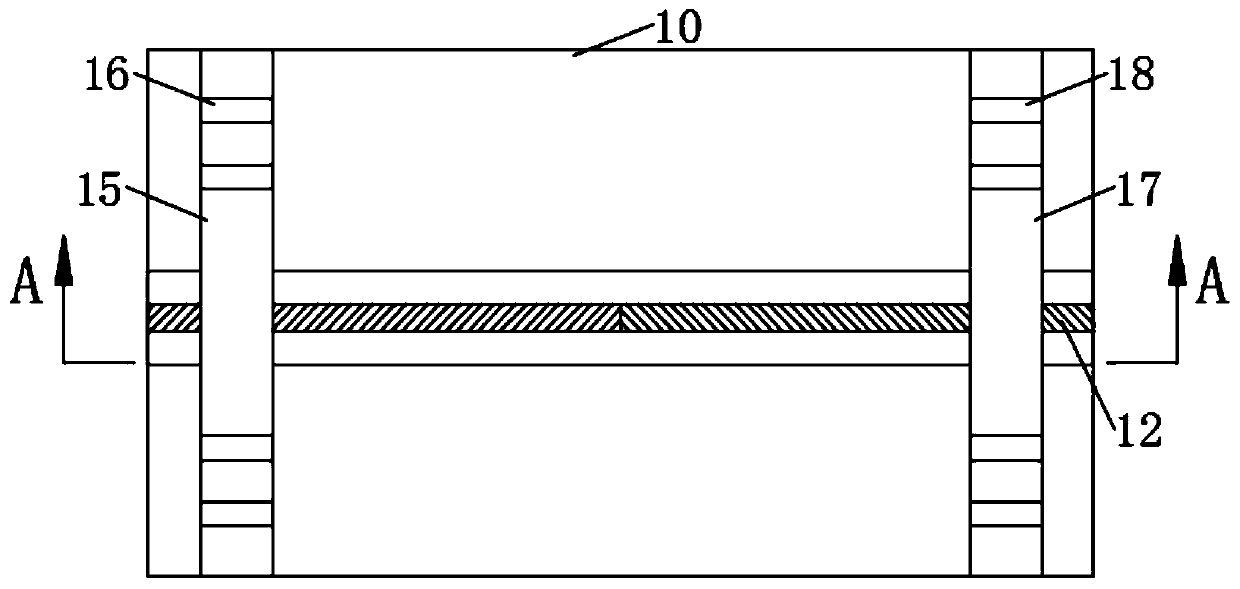

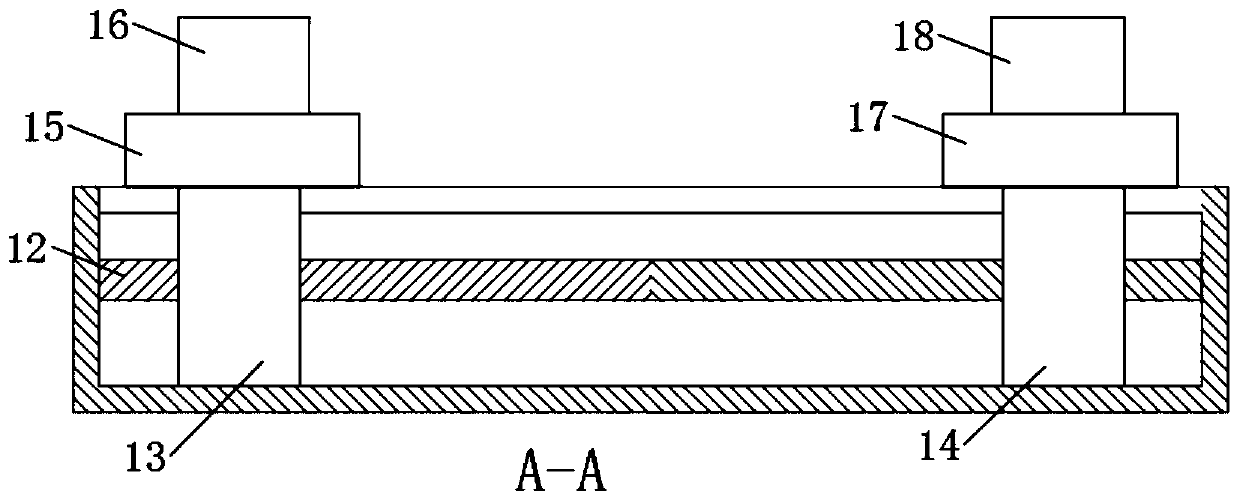

[0020] Such as Figure 1-4 As shown, this specific embodiment adopts the following technical solutions: a feeding device for processing fused silica particles, including a feeding device body 1, and the feeding device body 1 is composed of a support mechanism 2, a lifting mechanism 3, and a storage mechanism 4 , a conveying mechanism 5, a filter mechanism 6 and a blanking mechanism 7, the support mechanism 2 is composed of a base 8 and a universal wheel 9, the four corners of the bottom of the base 8 are not equipped with universal wheels 9, the base 8 The top is fixedly connected with a lifting mechanism 3, and the top of the lifting mechanism 3 is fixedly connected with a storage mechanism 4, and the top of the lifting mechanism 3 is fixedly connected with a delivery mechanism 5 at the side of the storage mechanism 4. Bottom is fixedly connected with filtering mechanism 6, and the bottom of described filtering mechanism 6 is provided with unloading mechanism 7, and described...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com