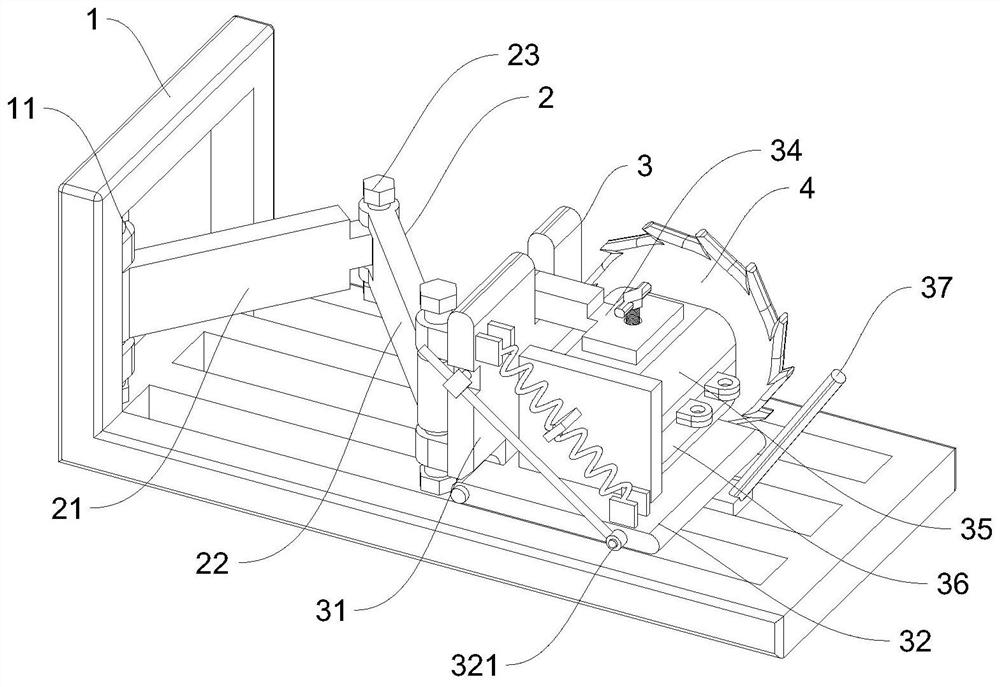

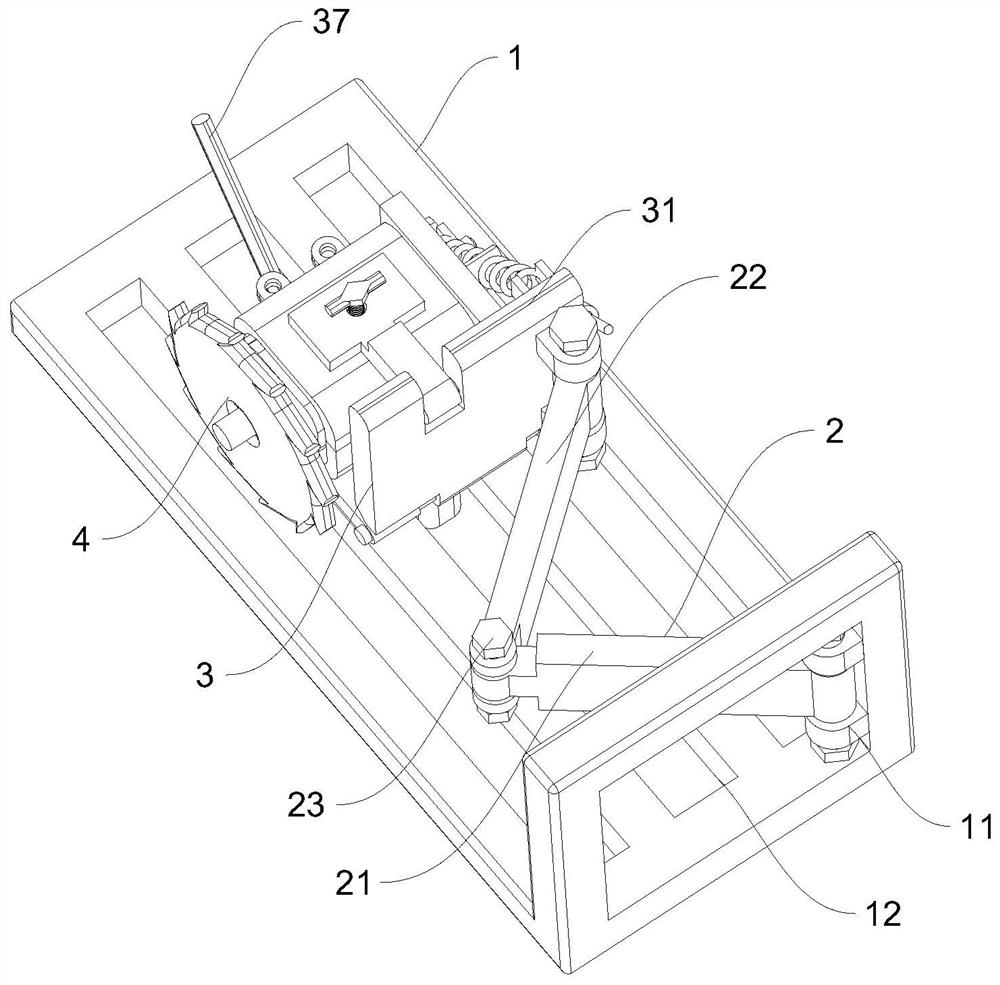

Cutting device for wood production and processing

A cutting device and wood technology, applied in the field of wood processing, can solve the problems of low wood production efficiency, cutting deviation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

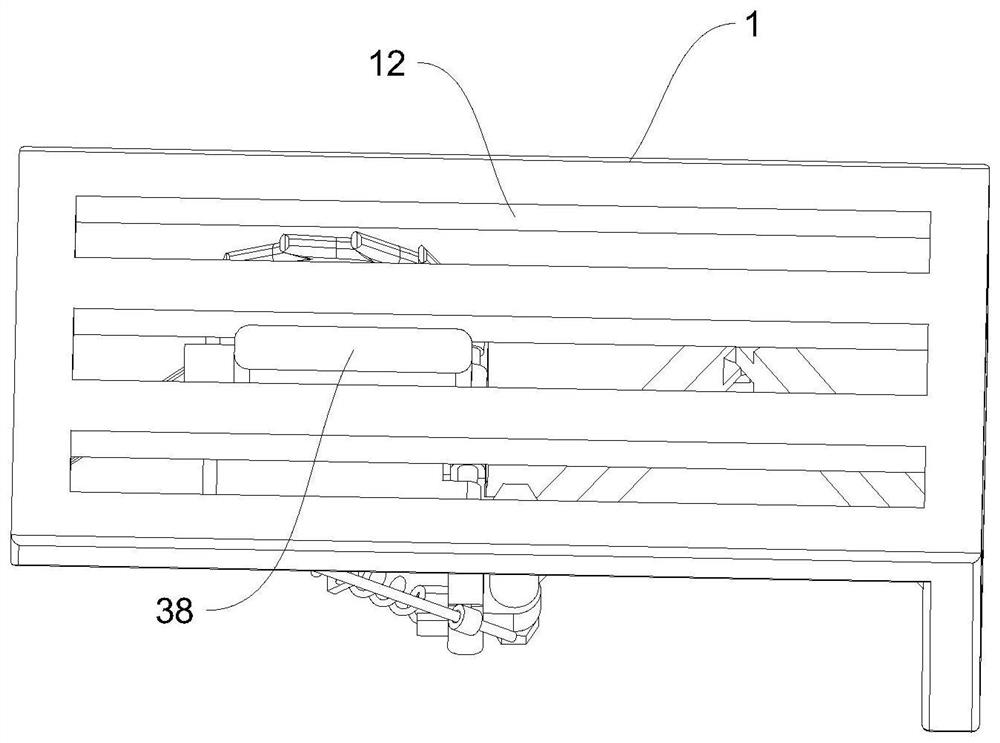

[0032] As an embodiment of the present invention, the bottom of the bottom plate 32 is fixedly connected with a slider 38; the bottom of the bottom plate 32 is fixedly connected with a lifting rod 37, and the lifting rod 37 is arranged at the front end of the sliding rod; One side of the backboard 31 is fixedly connected with a No. 2 connecting seat 33 .

[0033] During work, after the wood is fixed, it may be necessary to move the cutting machine body 4 to one end of the wood. At this time, by artificially driving the lifting rod 37 to move upward, the limiting mechanism 3 is indirectly driven to deflect at a certain angle, so that the cutting machine body 4 Separated from the sink 12, the movement of the limit mechanism 3 can be realized, and the lifting rod 37 can be lowered at a suitable position, and the cutting machine body 4 can be started to cut wood.

[0034] As an embodiment of the present invention, a collar 311 is rotatably connected to one end side wall of the backb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com