Drilling equipment for wooden mounting handle

A technology for punching equipment and handles, which is used in wood processing appliances, stationary drilling machines, forming/shaping machines, etc., can solve problems such as inconvenient collection and inconvenience in fixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

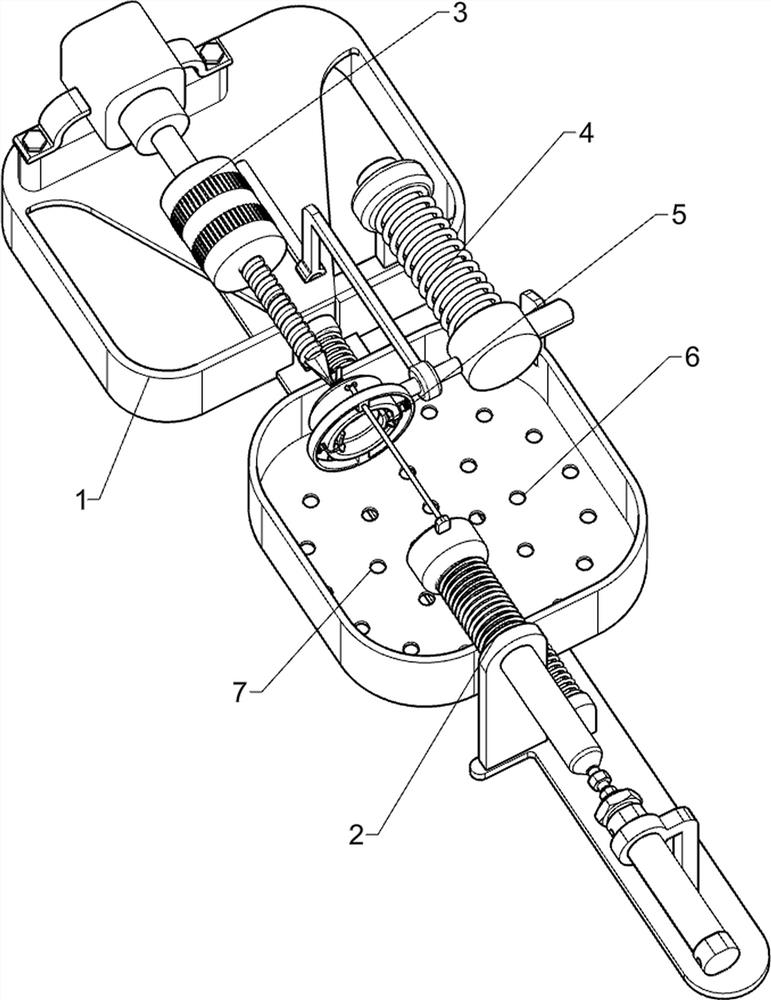

[0027] A wooden mounting handle punching device such as figure 1 , figure 2 and image 3 As shown, it includes a base 1 , a pushing mechanism 2 and a punching mechanism 3 , the pushing mechanism 2 is arranged on the top right side of the base 1 , and the punching mechanism 3 is arranged on the left side of the top of the base 1 .

[0028] When people need to punch holes in the wooden installation handle, this device can be used. First, the wooden installation handle is placed on the push mechanism 2. After the punching mechanism 3 is started, the push mechanism 2 is started again, and the push mechanism 2 will drive the wooden installation handle. Move to the left, when the punching mechanism 3 is in contact with the wooden installation handle, it will punch holes. After the punching is completed, close the push mechanism 2, and then close the punching mechanism 3, manually take out the wooden installation handle that has been punched, and arrange it That's it.

[0029] Th...

Embodiment 2

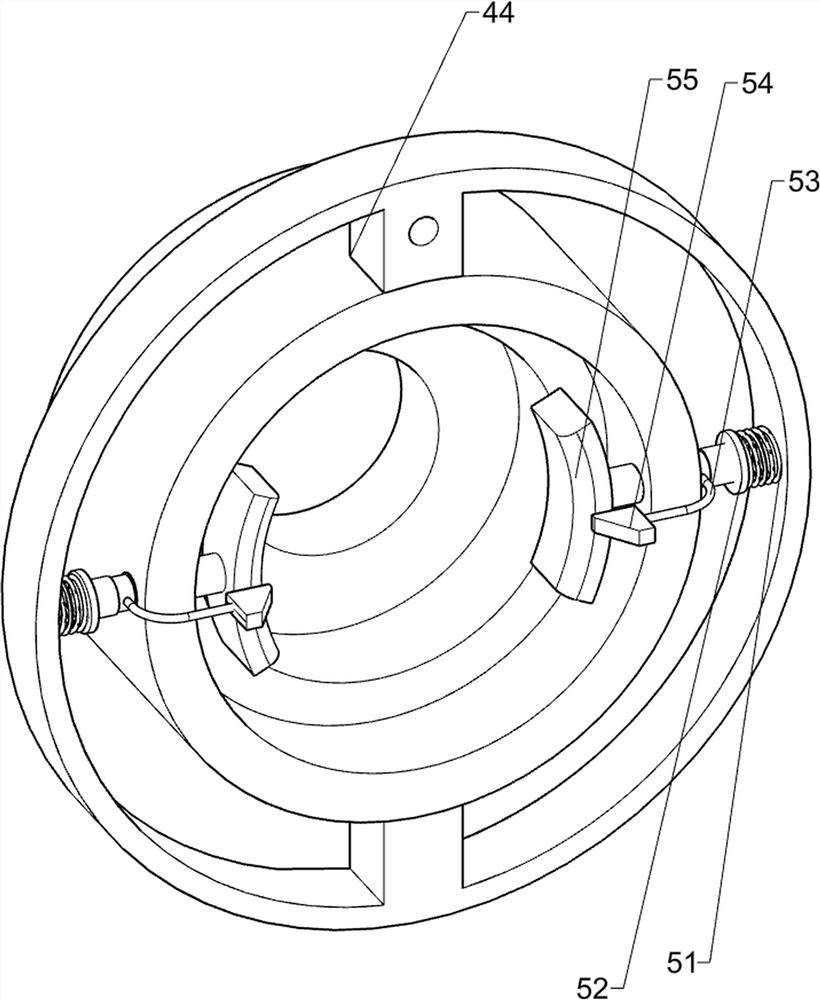

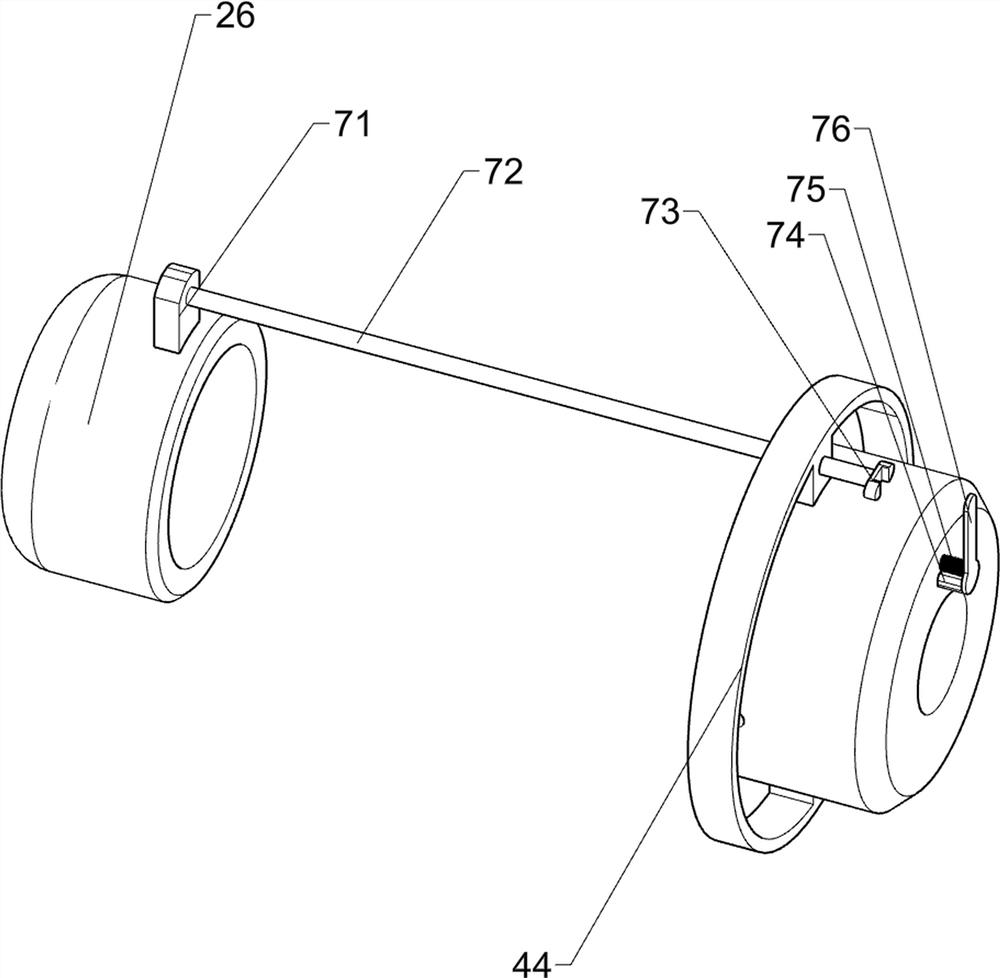

[0034] On the basis of Example 1, such as Figure 4 , Figure 5 , Figure 6 and Figure 7 As shown, a fixing mechanism 4 is also included, and the fixing mechanism 4 includes a third support column 41, a slide bar 42, a first connecting rod 43, a fixed frame 44, a first connecting block 45, a first top block 46, a second spring 47. The first guide rod 48 and the connecting collar 49, the top of the base 1 is provided with a sliding rod 42, the sliding rod 42 is provided with a third supporting column 41, and the right side of the third supporting column 41 is provided with a first connecting rod 43 , the front side of the first connecting rod 43 is provided with a fixed frame 44, the left rear side of the top of the base 1 is provided with a connecting collar 49, and the right side of the connecting collar 49 is slidably provided with a first guide rod 48, and the right side of the first guide rod 48 A first connecting block 45 is provided, the first connecting block 45 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com