Rear wheel structure of container cargo loader

A loader and cargo technology, applied in the direction of wheel, axle combination, transportation and packaging, etc., can solve the problems of troublesome disassembly and maintenance, small tire space and large space, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, further describe the technical solution of the present invention, but the present invention is not limited to these embodiments.

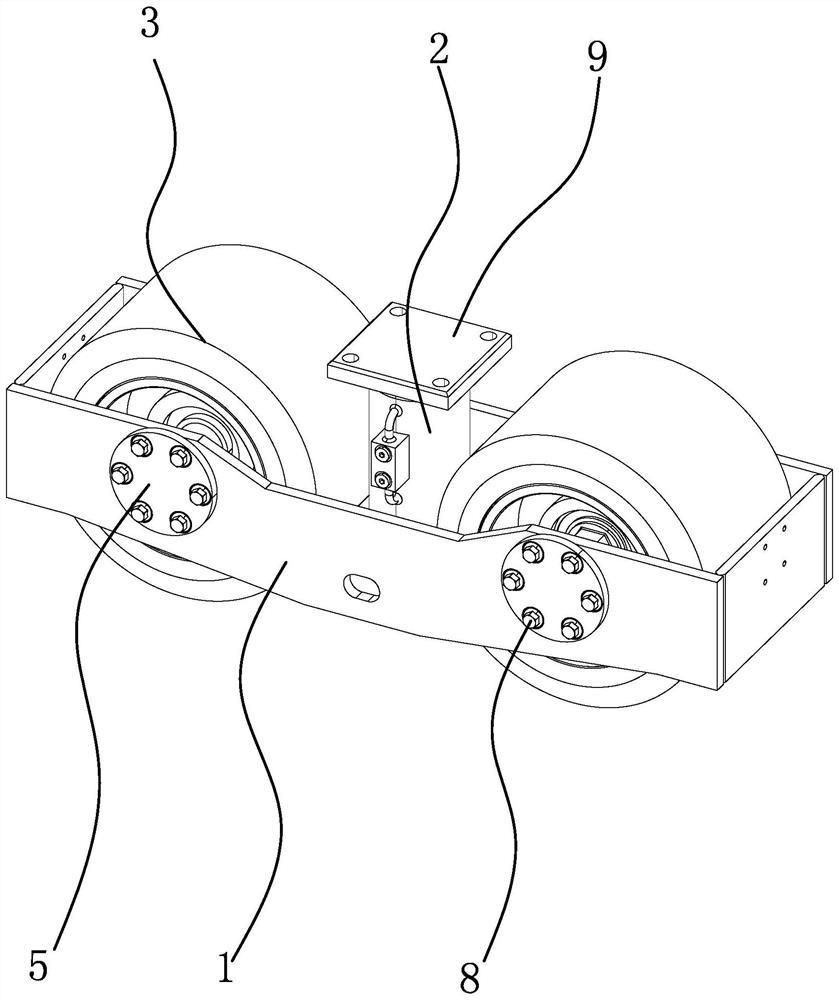

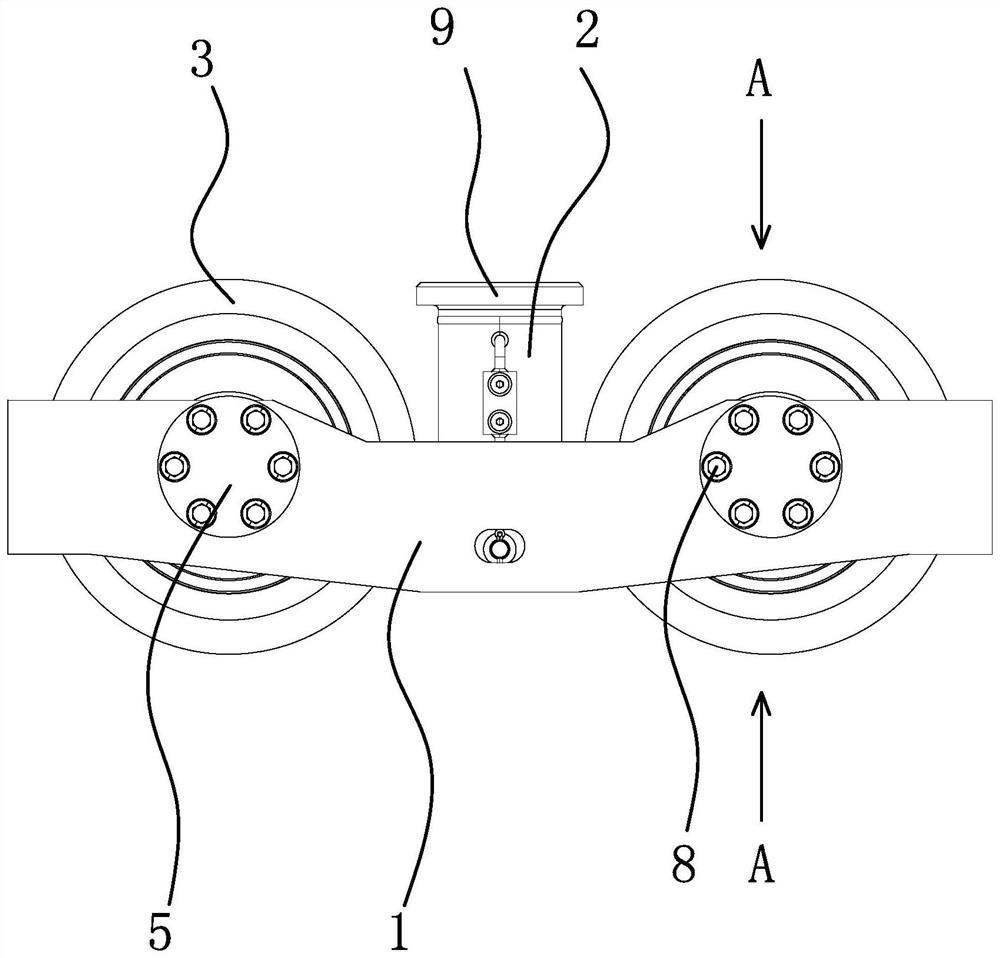

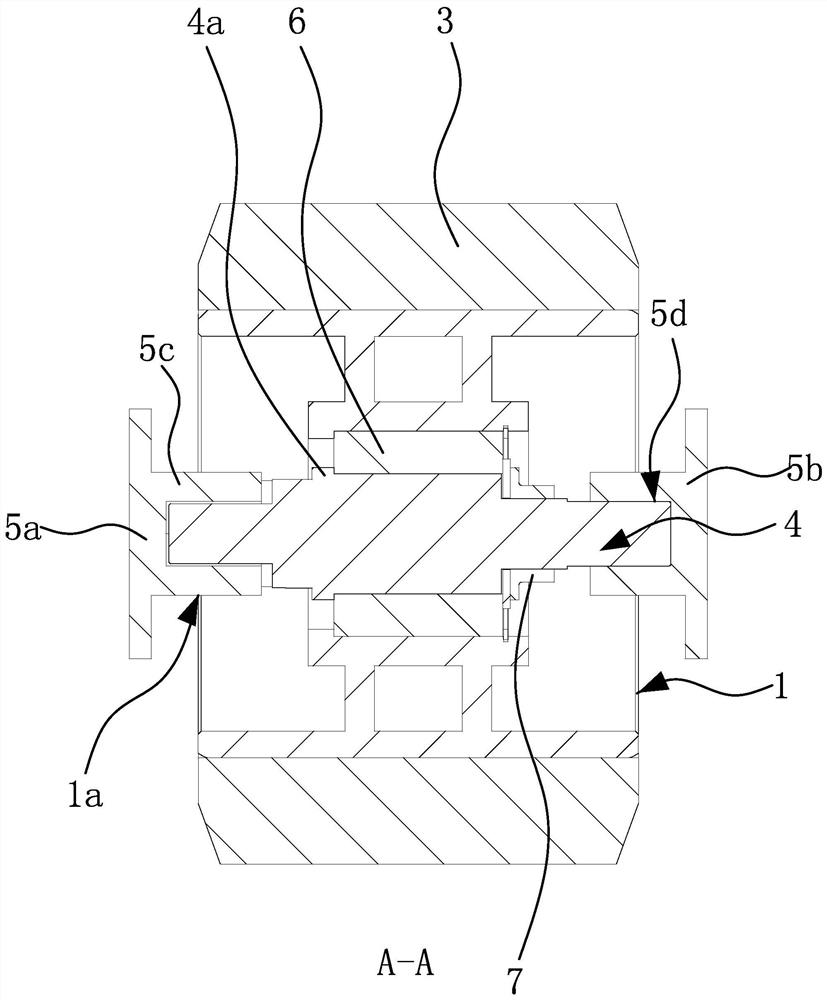

[0021] Such as figure 1 , figure 2 and image 3 As shown, the rear wheel structure of the containerized cargo loader includes a mounting bracket 1, the mounting bracket 1 is a rectangular frame structure, a hydraulic cylinder 2 is arranged on the mounting bracket 1, and the output shaft of the hydraulic cylinder 2 is arranged vertically upward. The top of 2 is provided with a mounting plate 9, the mounting plate 9 is a square board structure arranged horizontally, the four corners of the mounting plate 9 have connecting holes for connecting with the frame, and the mounting plate 9 is inserted into the connecting hole. Bolts are fixedly connected to the frame of the containerized cargo loader, the bottom end of the housing of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com