Touch screen assembly and AGV thereof

A touch screen and component technology, applied in the field of AGV vehicles, can solve the problems of the touch screen not working, affecting the appearance, and increasing the cost of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

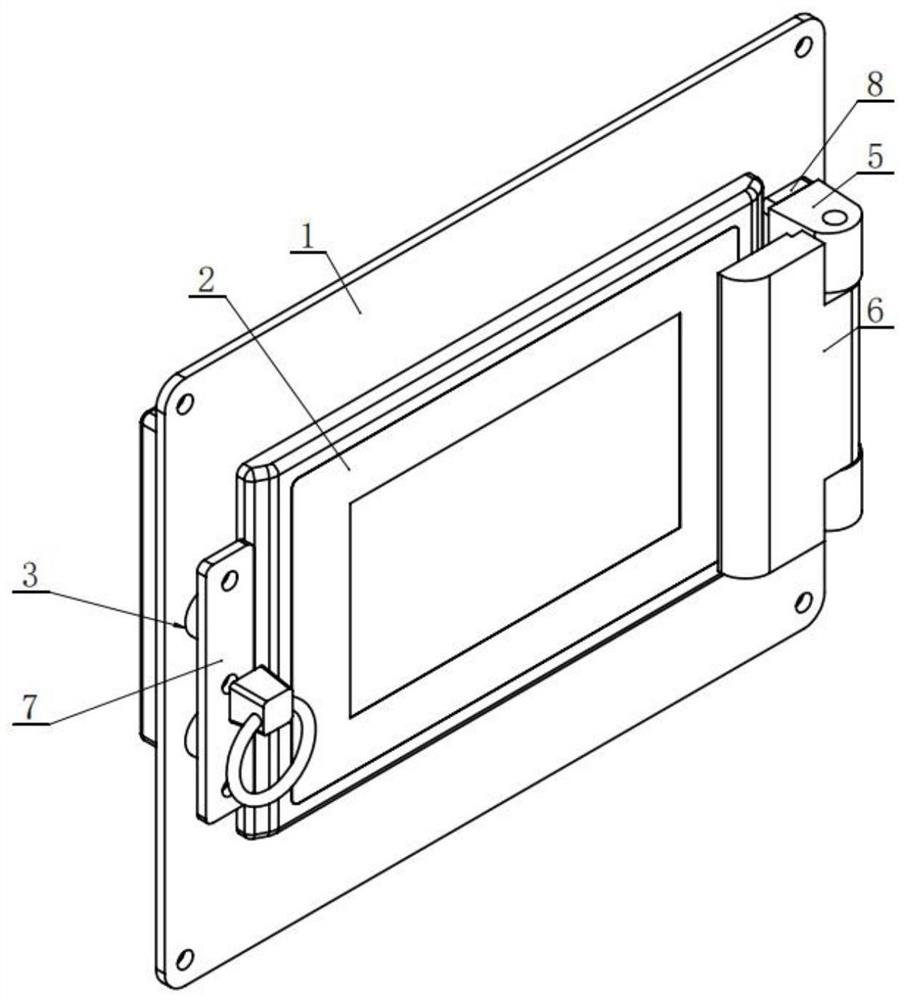

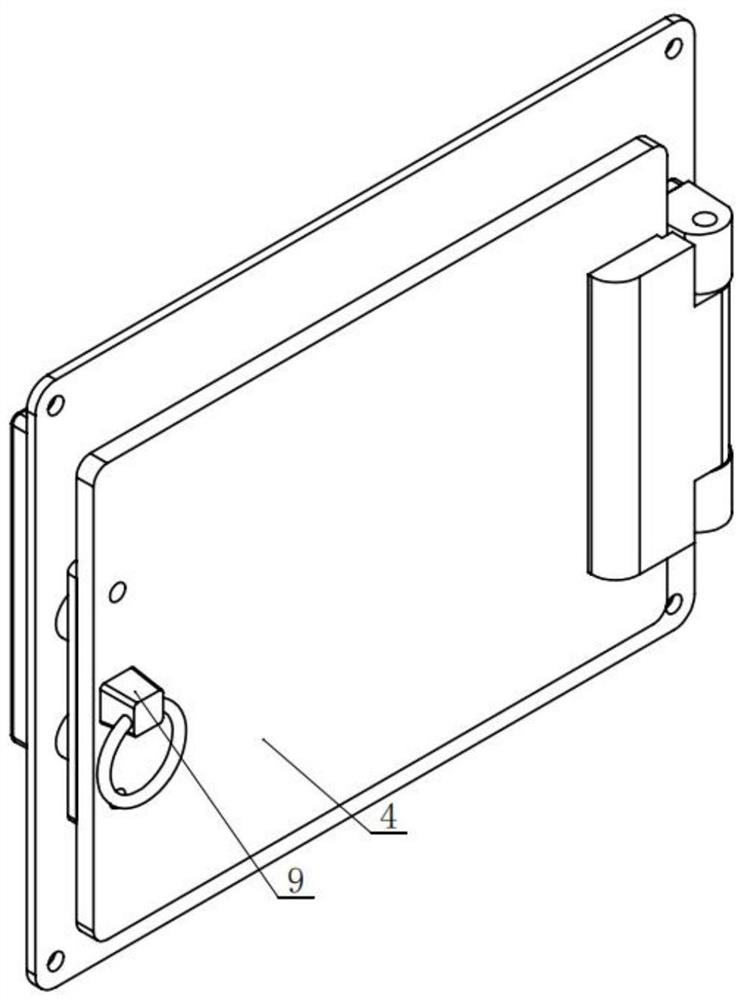

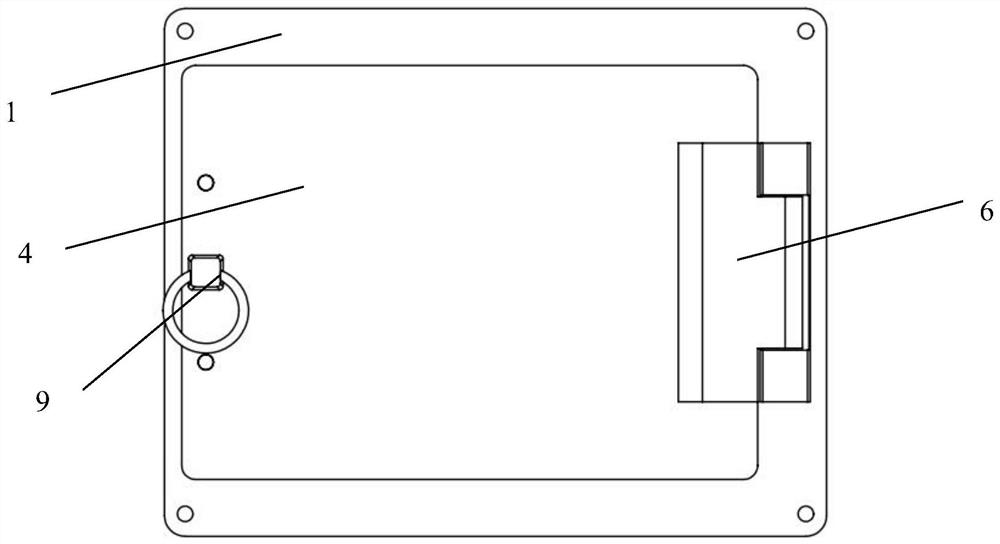

[0038] like figure 1 —— Figure 4 As shown, a touch screen assembly 100 includes a mounting board, a protective cover, and a touch screen. The protective cover is reversibly connected to one side of the mounting plate through a reversing mechanism. The touch screen is located between the installation board and the protective cover, and the touch screen is installed on the protective cover.

[0039] In the present invention, the specific structure of the protective cover is not limited. Here, the protective cover is parallel to the mounting plate to clamp the touch screen in the middle for protection; or the protective cover is embedded inside the mounting plate, and the touch screen is also embedded, so that the protection is more thorough; or the protective cover is relatively installed. A groove is provided on one side of the board for embedding the touch screen.

[0040] The shape of the mounting plate is set according to the needs of actual use and the through holes or ...

Embodiment 2

[0066] like figure 1 —— Figure 5 As shown, an AGV car is equipped with a touch screen assembly 100 on the car body 200, and the touch screen assembly 100 includes the touch screen assembly described in any one of the above. The touch screen assembly 100 includes a mounting board, a protective cover, and a touch screen. The protective cover is reversibly connected to one side of the mounting plate through a reversing mechanism. The touch screen is located between the installation board and the protective cover, and the touch screen is installed on the protective cover.

[0067] In this embodiment, the touch screen assembly is installed on the AGV body, and the car body is used as a transport vehicle in the workshop, which can effectively avoid damage to the touch screen, and at the same time ensure that the surface of the touch screen is clean.

[0068] In some embodiments, further: the touch screen assembly is installed on the left or right side of the forward direction of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com