General combination method for super-lift mast, crane and boom

A crane and recombination technology, applied in the direction of cranes, etc., can solve the problems of cost waste and poor versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

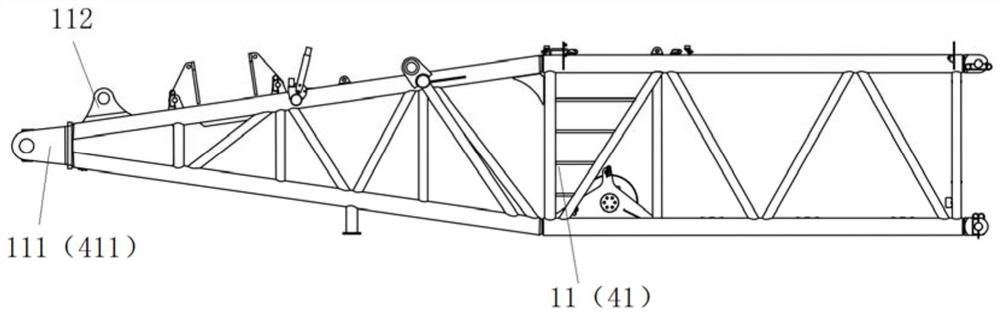

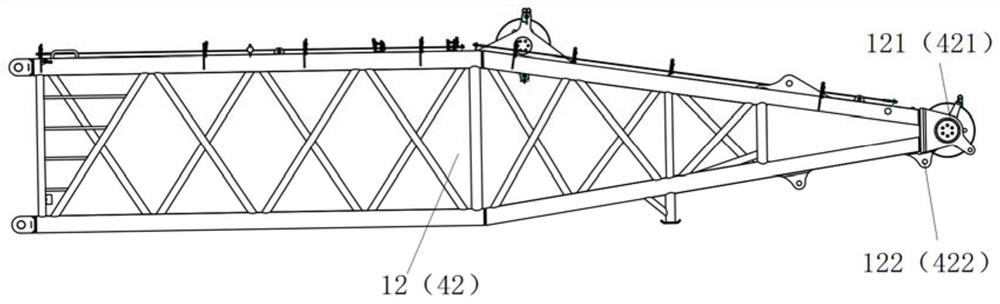

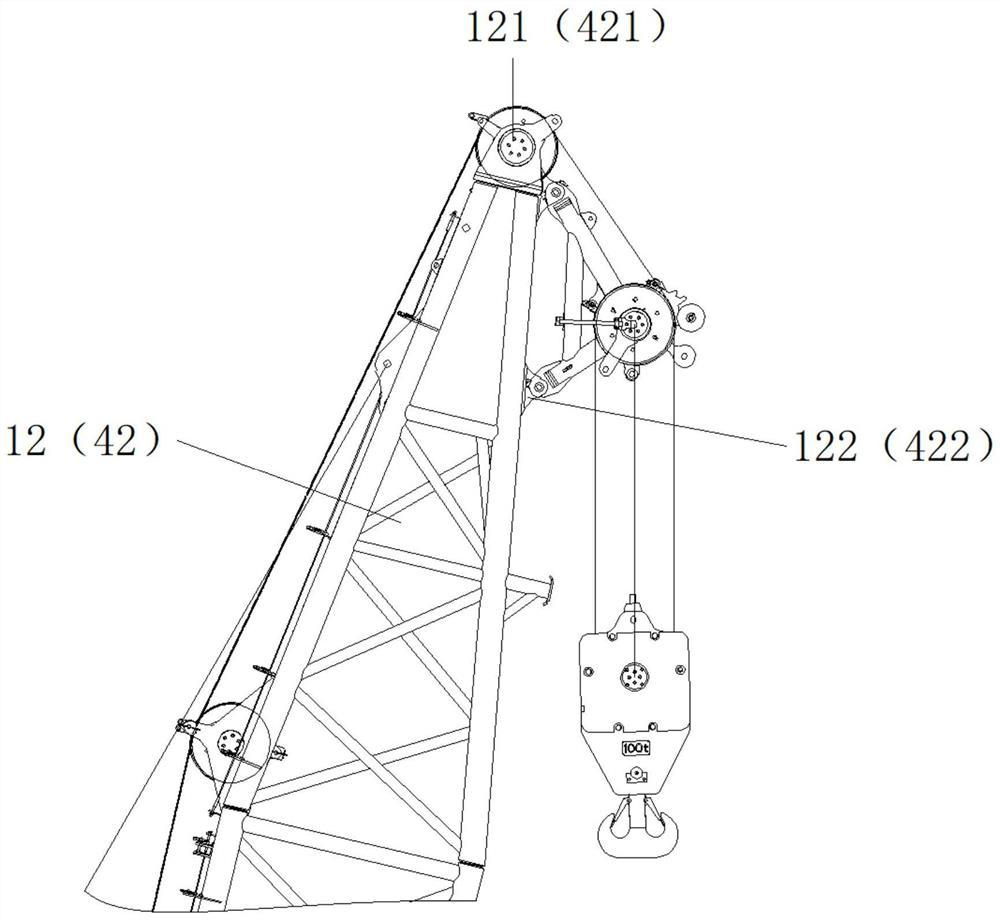

[0040] Such as Figures 1 to 3 A specific implementation of the superlift mast shown includes: a mast body, a first section arm 11 detachably connected to the first end of the mast body, and a second end detachably connected to the mast body The second section arm 12, the first section arm 11 is provided with a first interface structure 111 suitable for connecting with the turntable 20 or the main arm 30, the second section arm 12 is provided with a first pulley structure 121, and is suitable for The first installation part 122 of the second pulley structure is installed.

[0041] In this embodiment, the first end of the mast body is the lower end of the mast body, the first section arm 11 is the lower section arm, the second end of the mast body is the upper end of the mast body, and the second section arm 12 is upper arm.

[0042] By setting the first interface structure 111 and the first installation part 122, when the pulley is installed on the first installation part 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com