A nanobubble-based sewage treatment device

A sewage treatment device and nano-bubble technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, filtration treatment, etc., can solve the large difference in aeration effect of micro-nano aeration tubes and shorten the service life , Poor aeration effect and other problems, to achieve the effect of improving poor aeration effect, reducing blockage, and equalizing air pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

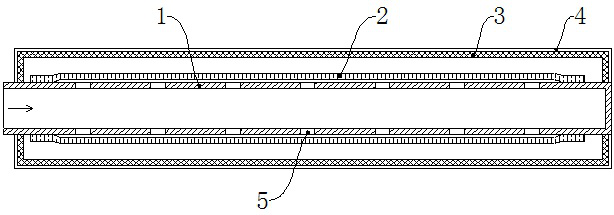

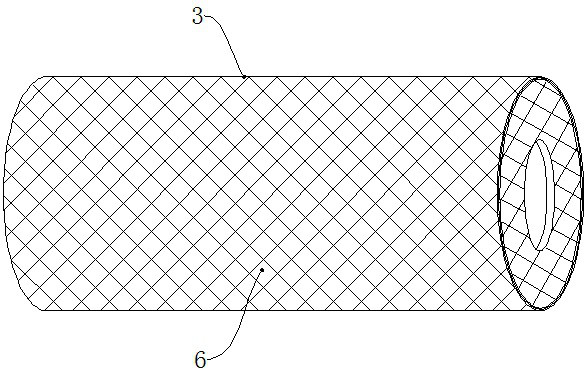

[0026] see figure 1 and 2 , this embodiment provides a nano-bubble-based sewage treatment device, including a rigid inner air pipe 1, one end of the rigid inner air pipe 1 is connected to the air source, and the other end is sealed; the outer side of the rigid inner air pipe 1 is sleeved with elastic micro Nano-aeration tube 2, both ends of the elastic micro-nano aeration tube 2 are airtightly connected with the outer side of the rigid inner air tube 1; corresponding to the side wall of the rigid inner air tube 1 in the elastic micro-nano aeration tube 2, a number of first ventilation holes 5 are provided. The outer side of the rigid inner trachea 1 is sleeved with a rigid holding pipe 3, the two ends of the rigid holding pipe 3 are fixedly connected to the outside of the rigid inner trachea 1, and the elastic micro-nano aeration pipe 2 is located in the rigid holding pipe 3. , there is a gap between the elastic micro-nano tube 2 and the rigid holding pipe 3; the rigid holdin...

Embodiment 2

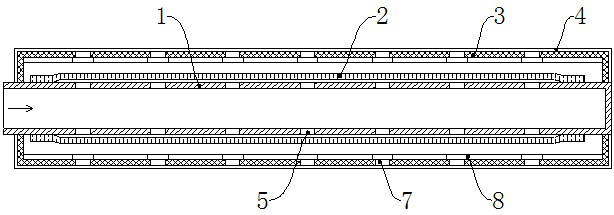

[0032] see image 3 and 4 , this embodiment provides a nano-bubble-based sewage treatment device, including a rigid inner air pipe 1, one end of the rigid inner air pipe 1 is connected to the air source, and the other end is sealed; the outer side of the rigid inner air pipe 1 is sleeved with elastic micro Nano-aeration tube 2, both ends of the elastic micro-nano aeration tube 2 are airtightly connected with the outer side of the rigid inner air tube 1; corresponding to the side wall of the rigid inner air tube 1 in the elastic micro-nano aeration tube 2, a number of first ventilation holes 5 are provided. The outer side of the rigid inner trachea 1 is sleeved with a rigid holding pipe 3, the two ends of the rigid holding pipe 3 are fixedly connected to the outside of the rigid inner trachea 1, and the elastic micro-nano aeration pipe 2 is located in the rigid holding pipe 3. , there is a gap between the elastic micro-nano tube 2 and the rigid holding pipe 3; the rigid holdin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com