A heat storage concrete and its preparation method

A technology of concrete and heat storage, applied in the field of building materials, can solve the problems of thermal cycle stability and durability to be improved, heat storage and release efficiency reduction, poor compatibility of concrete, etc., to increase thermal cycle stability and reduce volume Swelling and cracking, increasing compactness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

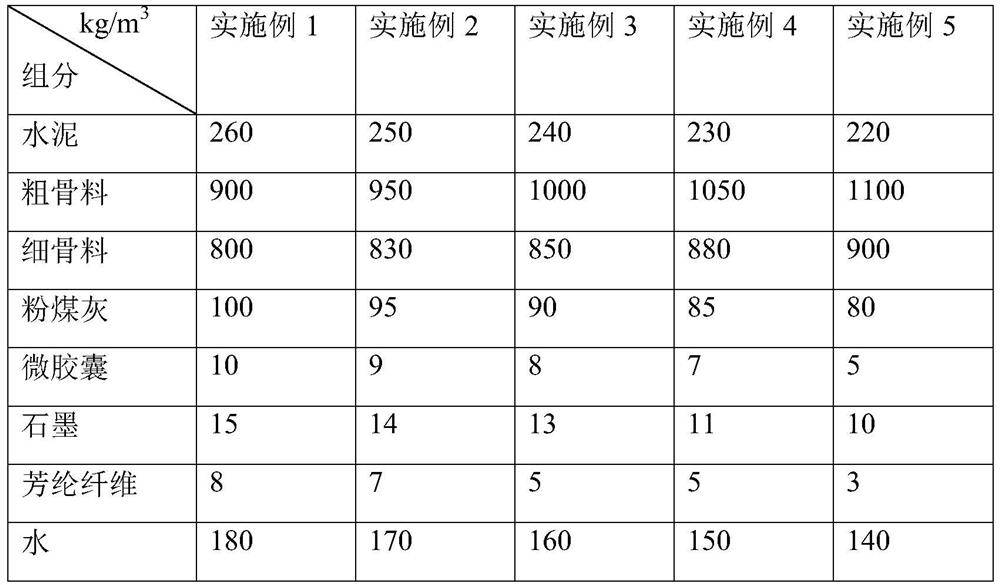

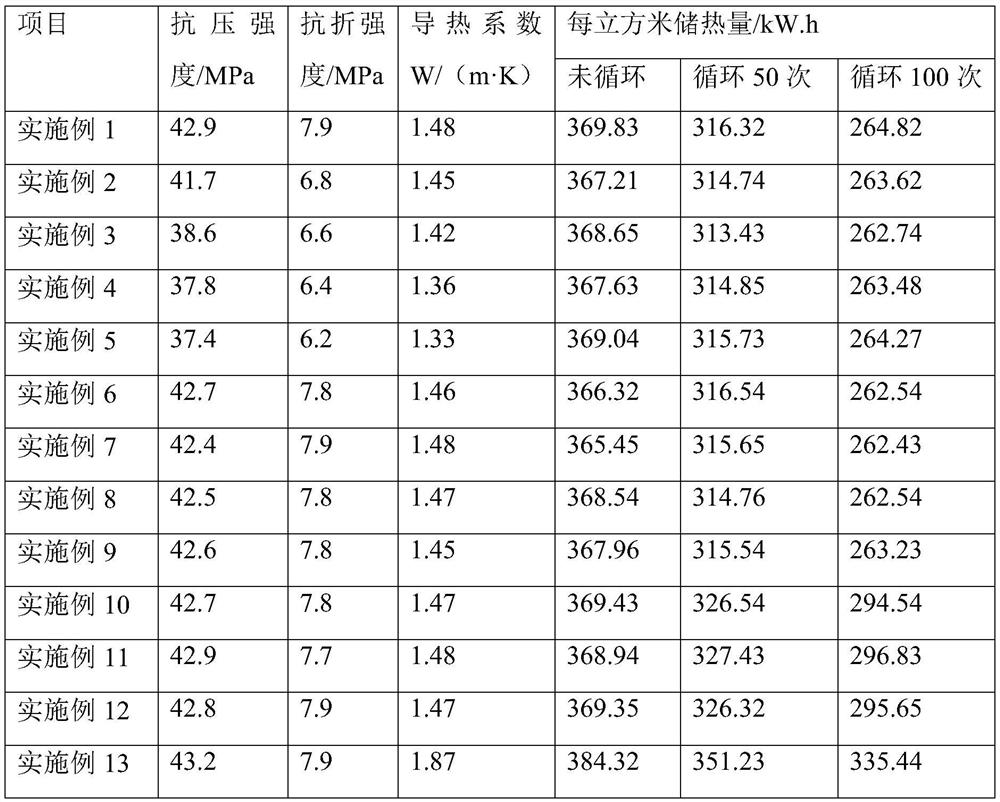

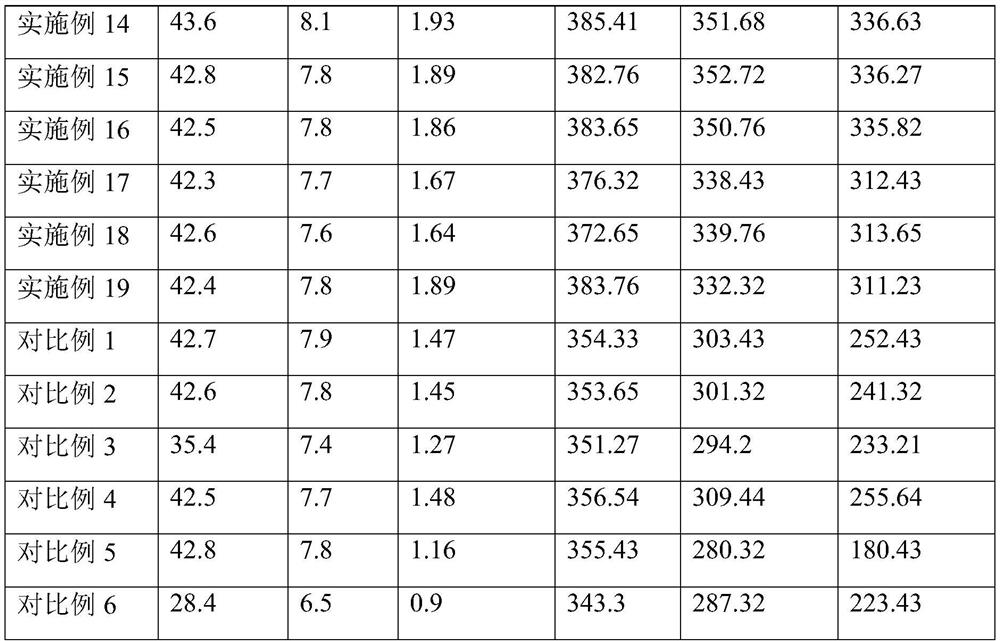

Examples

preparation example 1-3

[0039] In Preparation Example 1-3, the silane coupling agent was selected from Guangzhou Suixin Chemical Co., Ltd., and the model was KH550, and the graphite oxide was selected from Nanjing Xianfeng Nanomaterials Technology Co., Ltd., and the model was NF003.

preparation example 1

[0040] Preparation Example 1: Disperse 0.2kg of silane coupling agent, 2kg of graphite oxide and 5kg of water evenly with a power of 200W ultrasonically, adjust the pH to 4.5 with citric acid to obtain a graphite oxide dispersion, add 5kg of paraffin, and place in a water bath at 70°C. Melt in medium, then emulsify at 16000rpm for 30min to obtain paraffin.

preparation example 2

[0041] Preparation Example 2: Disperse 0.3kg of silane coupling agent, 4kg of graphite oxide and 8kg of water evenly with a power of 250W ultrasonically, adjust the pH to 4.8 with citric acid to obtain a graphite oxide dispersion, add 8kg of paraffin, and place in a water bath at 75°C. Melt in medium, then emulsify at 17000rpm for 25min to obtain paraffin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com