Chlorinated polyethylene composition containing black phosphorus (alkene) and application of composition

A technology of chlorinated polyethylene and composition, applied in the field of chlorinated polyethylene composition containing black phosphorus, can solve the problem of reduced fluidity and mechanical properties in chlorinated polyethylene processing, poor processing fluidity of chlorinated polyethylene, and chlorination of chlorinated polyethylene. The problem of flame retardancy of polyethylene, etc., to achieve the effect of maintaining flame retardancy and mechanical properties, improving mechanical properties, and good flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A chlorinated polyethylene composition containing black phosphorus (ene), containing the following raw materials in parts by weight: plastic type chlorinated polyethylene CPE-135A: 65%, black phosphorus powder (average size 5 microns): 3%, Melamine: 2%, Chlorinated Paraffin-42: 8%, Epoxidized Soybean Oil: 2%, Semi-reinforcing Carbon Black: 10%, Aluminum Hydroxide: 10%.

[0048] Spline preparation method: weigh chlorinated polyethylene and add it to the rubber mill for plastication. After evenly covering the rolls, adjust the distance between the rolls to 1mm. Add the evenly mixed mixture of epoxy soybean oil, melamine and black phosphorus powder, and then add Chlorinated paraffin, carbon black, aluminum hydroxide, mixed for 20 minutes, mixed evenly and then granulated.

Embodiment 2

[0050] A chlorinated polyethylene composition containing black phosphorus (ene), containing the following raw materials in parts by weight: rubber type chlorinated polyethylene CM-135B: 52%, black phosphorus powder (average particle size 1 micron): 4 %, melamine: 3%, dicumyl peroxide DCP: 3%, triallyl isocyanurate TAIC: 1%, semi-reinforcing carbon black: 15%; dioctyl sebacate DOS: 14% , highly active magnesium oxide: 8%.

[0051] Spline preparation method: weigh the chlorinated polyethylene rubber material and add it to the rubber internal mixer for mastication, the speed is 40 rpm, add the evenly mixed DOS, melamine and black phosphorus powder mixture, after mixing evenly, add charcoal in sequence Black, magnesia, TAIC, DCP, the materials mixed evenly are added to the rubber filter. The filtered material is cold-fed to an extruder for extrusion molding, or formed on a calender. Finally, the product is vulcanized on a vulcanizing machine.

Embodiment 3

[0053] A chlorinated polyethylene multifunctional masterbatch containing black phosphorus (ene), used for PVC door and window profiles. Raw materials containing the following parts by weight: plastic type chlorinated polyethylene PE-C (melting enthalpy 10J / G, chlorine content 35%): 55%, black phosphorus powder (average size 5 microns): 15%, melamine: 10% , Chlorinated Paraffin-42: 15%, Epoxidized Soybean Oil: 5%.

[0054] Preparation method: Weigh 5 kinds of materials such as chlorinated polyethylene and add them to the rubber mill for plastication. After evenly wrapping the rolls, adjust the distance between the rollers to 1 mm, and knead for 20 minutes. Mixing granulation to prepare functional masterbatch.

[0055] This functional masterbatch can be used for molding PVC door and window profiles, and the specific usage ratio is CPE functional masterbatch:PVC resin=1:10.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

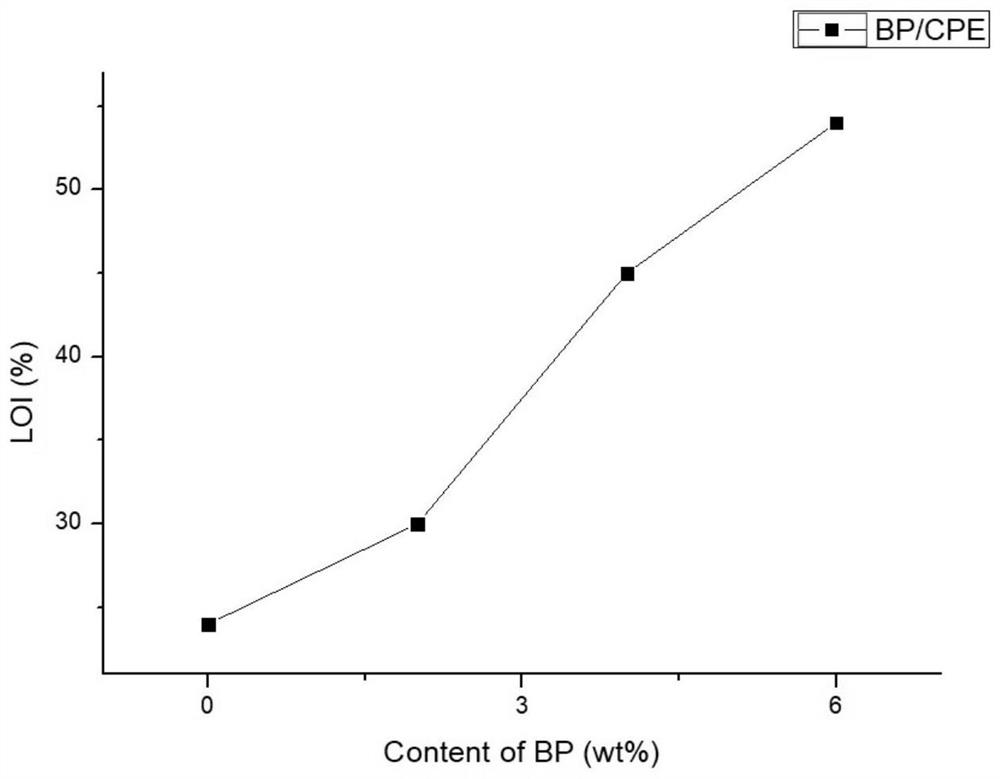

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com