Quickly positioning highly waterproof ultra-high-performance concrete combined permanent template

A permanent formwork and ultra-high performance technology, applied in water conservancy projects, underwater structures, bridge parts, etc., can solve problems such as leakage and affecting structural durability, and achieve improved durability, improved structural durability, and durability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

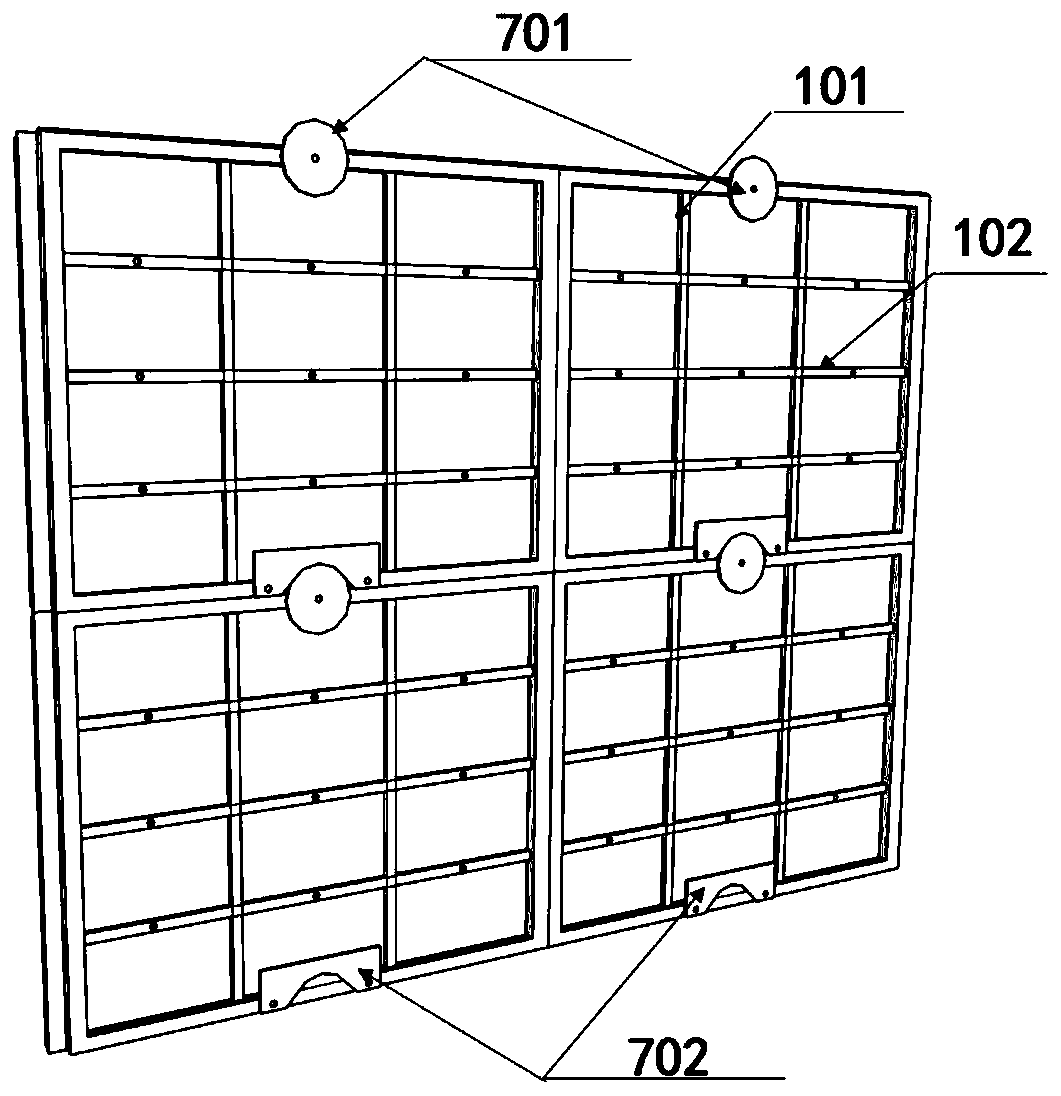

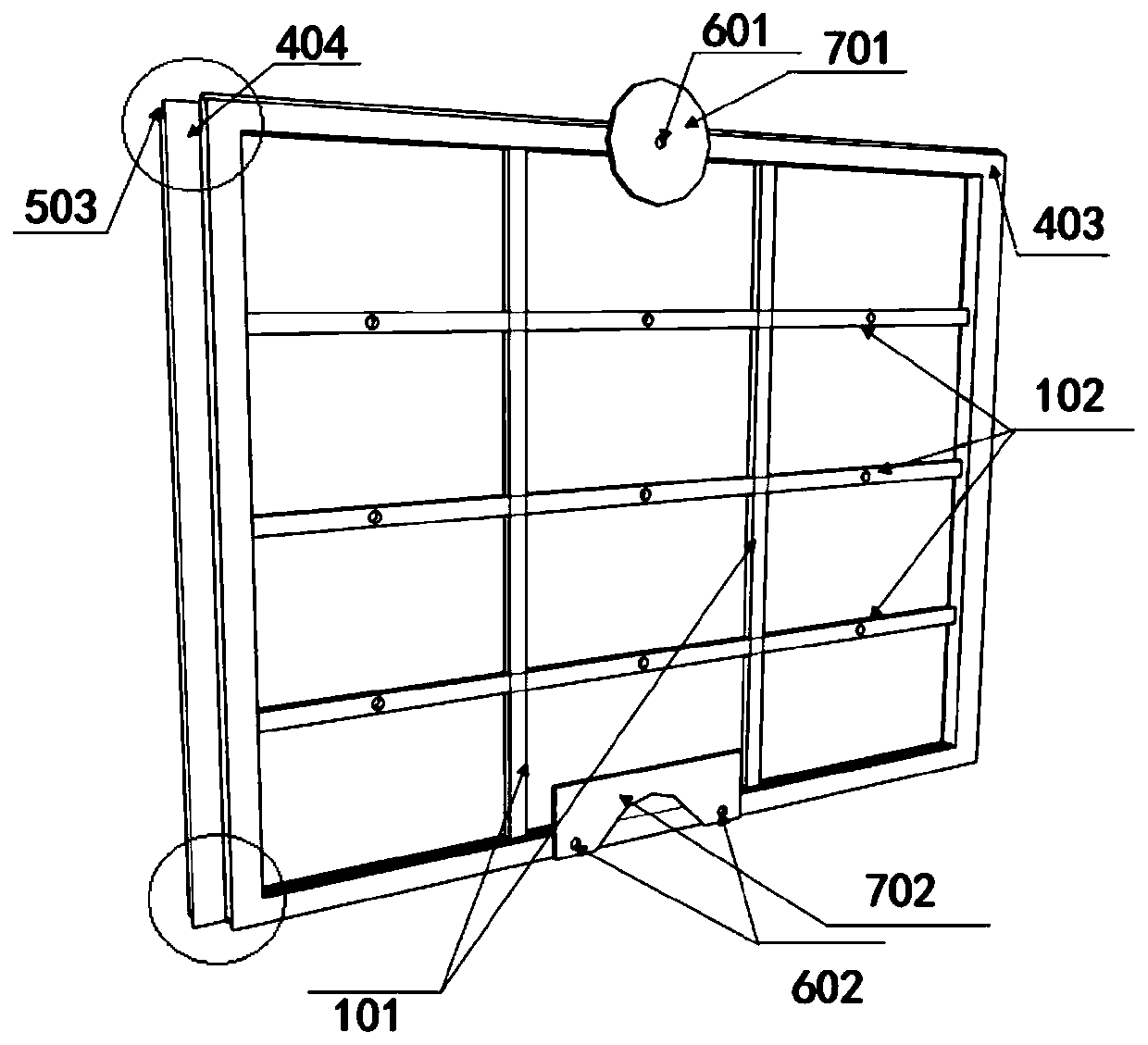

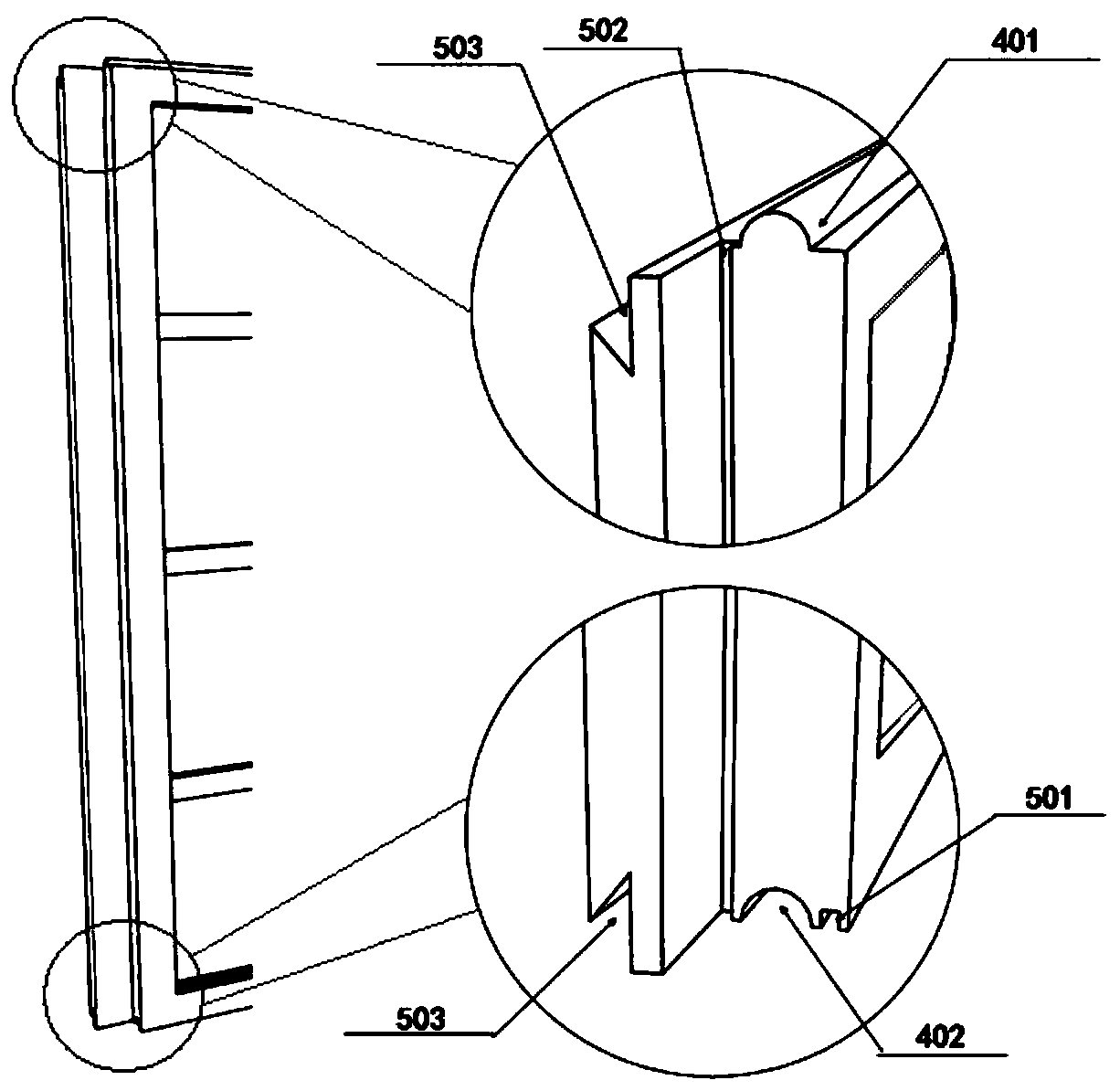

[0045] A fast-positioning high-waterproof ultra-high-performance concrete combined permanent formwork in this embodiment, its structural schematic diagram is as follows Figure 1~6 shown. The outer side of the permanent template is a plane with a size of 900×600 mm and a plane thickness of 15 mm. The plane material is ultra-high performance concrete reinforced with organic fiber mesh; the inner side is ribbed, and the ribs are arranged horizontally and vertically. Set 3 ribs 102, the width of the ribs is 30mm, and the height of the ribs does not exceed the height of the edge; the thickness of the four edges is 30mm, and a tongue and groove is provided, and the overlapping part of the tongue and groove is a hydrophobic surface; the upper edge of the permanent formwork and The tongue-and-groove of the lower edge is set as a corresponding semicircular protrusion 401 and groove 402 to form a card slot with a height or depth of 10 mm. A long rectangular groove 501 is set near the ...

Embodiment 2

[0051] A fast-positioning high-waterproof ultra-high-performance concrete combined permanent formwork in this embodiment, the outer side of the permanent formwork is a plane, the size is 3000×2400mm, the plane thickness is 30mm, and the plane material is ultra-high-performance concrete reinforced by stainless steel wire mesh ; Ribs on the inner side, the ribs are set horizontally and vertically, 2 ribs are set vertically, and 3 ribs are set horizontally, the width of the ribs is 40mm, and the height of the ribs does not exceed the height of the sides; the thickness of the four sides is 60mm, and the height of the ribs is set The tongue and groove overlap is a hydrophobic surface; the tongue and groove on the upper and lower sides of the permanent formwork is set as a corresponding arc-shaped protrusion and groove to form a card slot, and its height or depth is 20mm. Set a long rectangular groove near the inside of the template in the length direction of the semicircular protrus...

Embodiment 3

[0058] A fast-positioning, waterproof and ultra-high-performance concrete combined permanent formwork in this embodiment, the outer side of the permanent formwork is a plane, the size is 4500×2400mm, the plane thickness is 40mm, and the plane material is ultra-high-performance concrete reinforced by stainless steel wire mesh ; The inner side is ribbed, the ribs are set horizontally and vertically, 2 ribs are set vertically, and 5 ribs are set horizontally, the width of the ribs is 50mm, and the height of the ribs is consistent with the height of the sides; the thickness of the four sides is 80mm, and set The tongue and groove overlap is a hydrophobic surface; the tongue and groove on the upper and lower sides of the permanent formwork is set as a corresponding arc-shaped protrusion and groove to form a card slot, and its height or depth is 30mm. A long rectangular groove is set near the inner side of the template in the length direction of the arc-shaped protrusion and groove. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com