Large/ultra-large biogas digester suitable for dry continuous fermentation

A fermentation tank and biogas tank technology, applied in the field of environmental protection, can solve the problems of difficult discharge and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

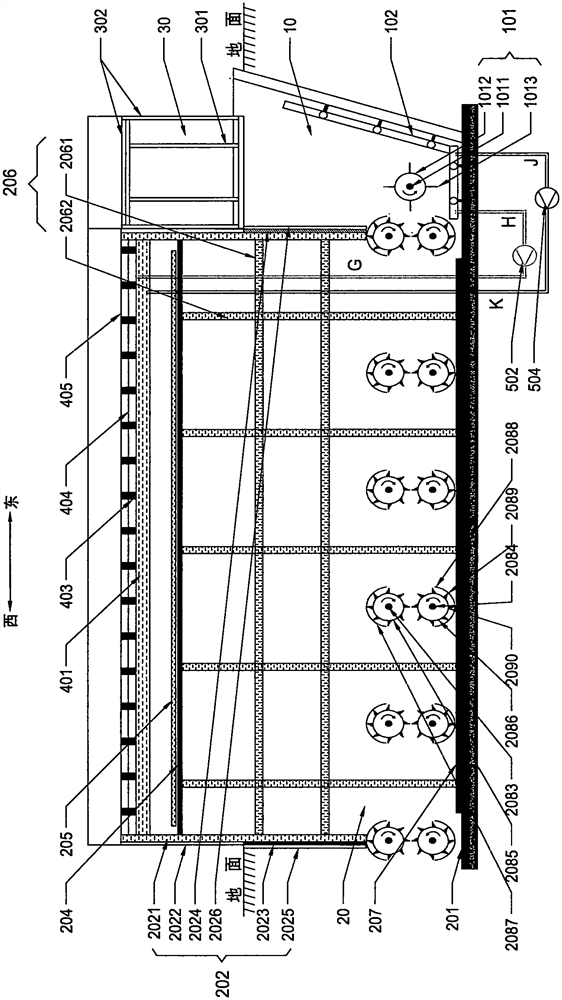

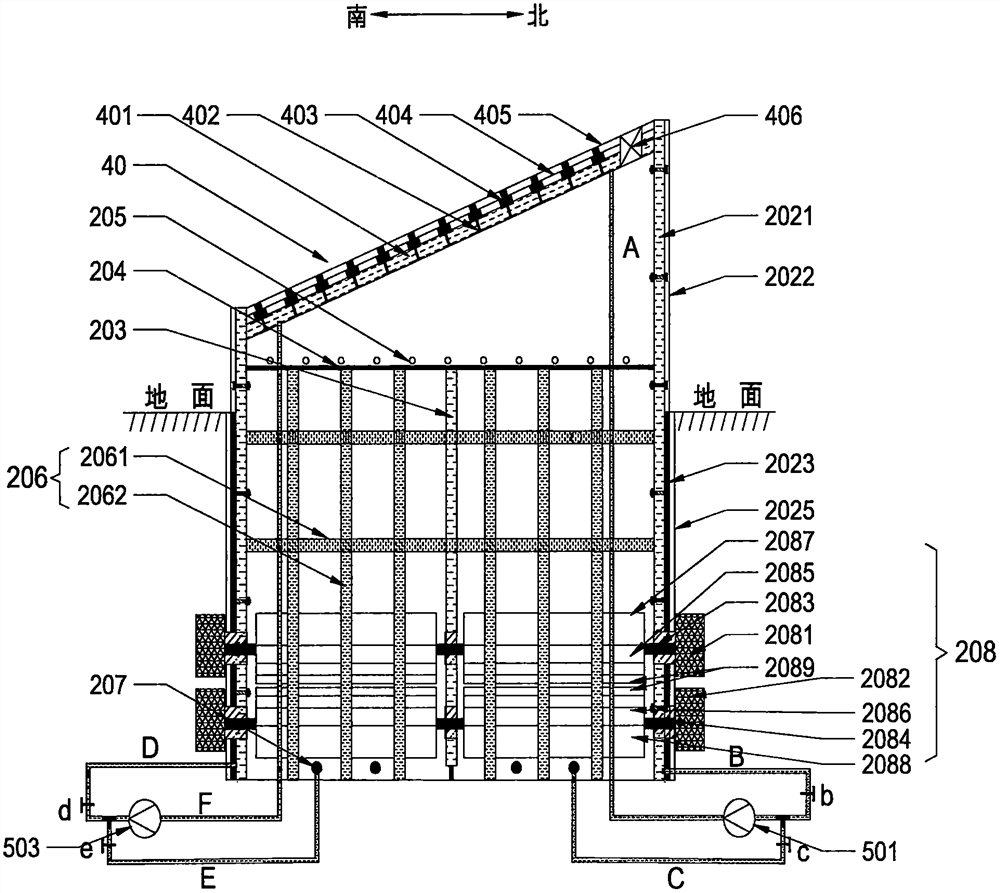

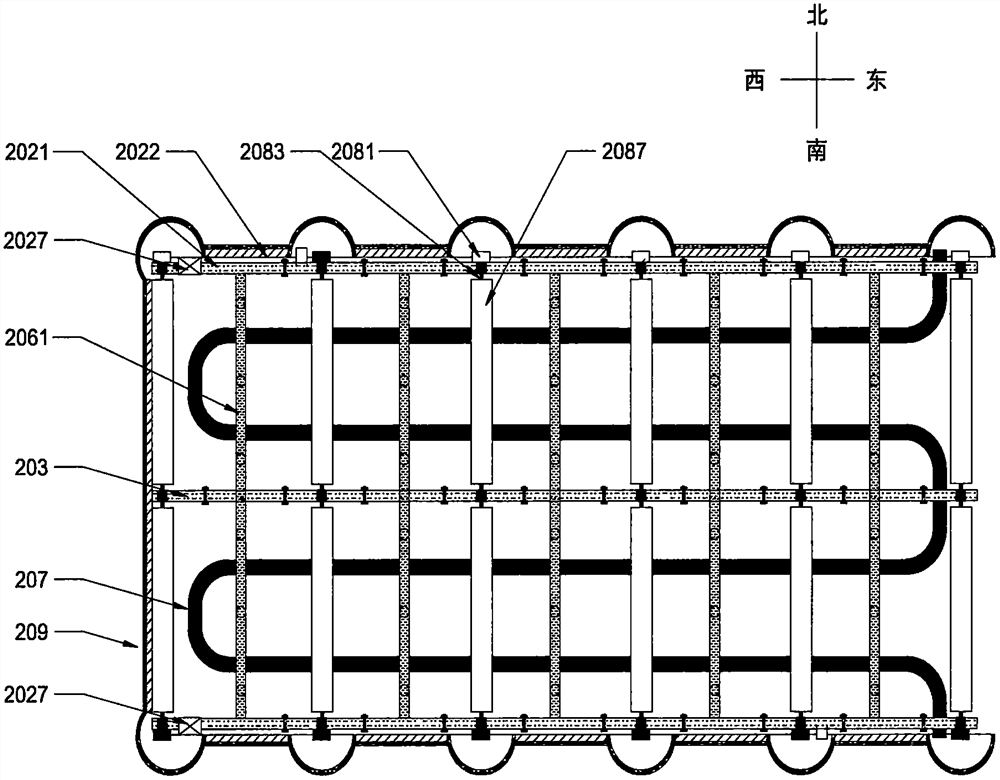

[0053] The biogas digester disclosed by the invention is rectangular, with the width in the north-south direction and the length in the east-west direction. Biogas digesters of different lengths can be built according to the gas demand, and can be built underground, semi-above or fully above the ground according to the climate conditions of the construction site. Type biogas pool.

[0054] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

[0055] refer to figure 1 , figure 2 and image 3 , the biogas digester disclosed by the present invention comprises: a feeding pond 10, a fermentation pond 20, a sun room 30, a heat collecting high-temperature water tank 40 and an automatic temperature control system, wherein the feeding pond 10 is built on the east side, and the fermentation pond 20 is built on the west side. On the other hand, the two are conjoined; the sunshine room 30 is built directly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com