Annealing device for cold-rolled stainless steel machining line

A technology of cold-rolled stainless steel and annealing device, which is applied to manufacturing tools, furnaces, heat treatment equipment, etc., can solve the problems of annealing effect, the annealing device does not have the function of air flow, and the heating temperature of the device cannot be used for heat recovery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with accompanying drawing:

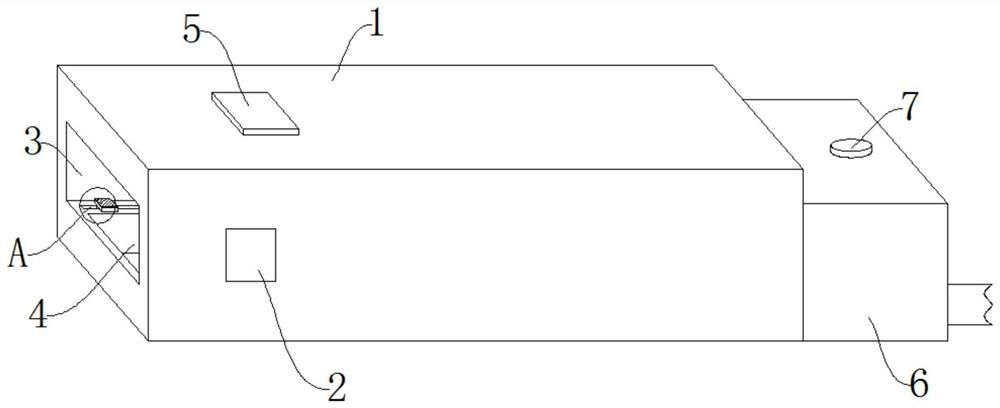

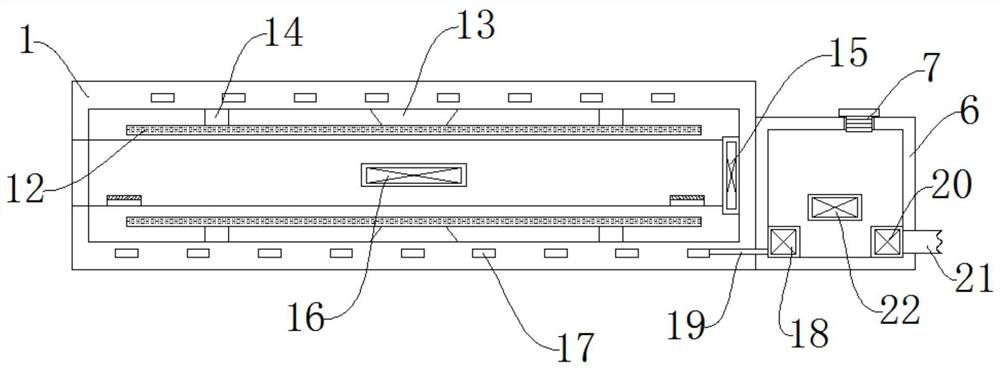

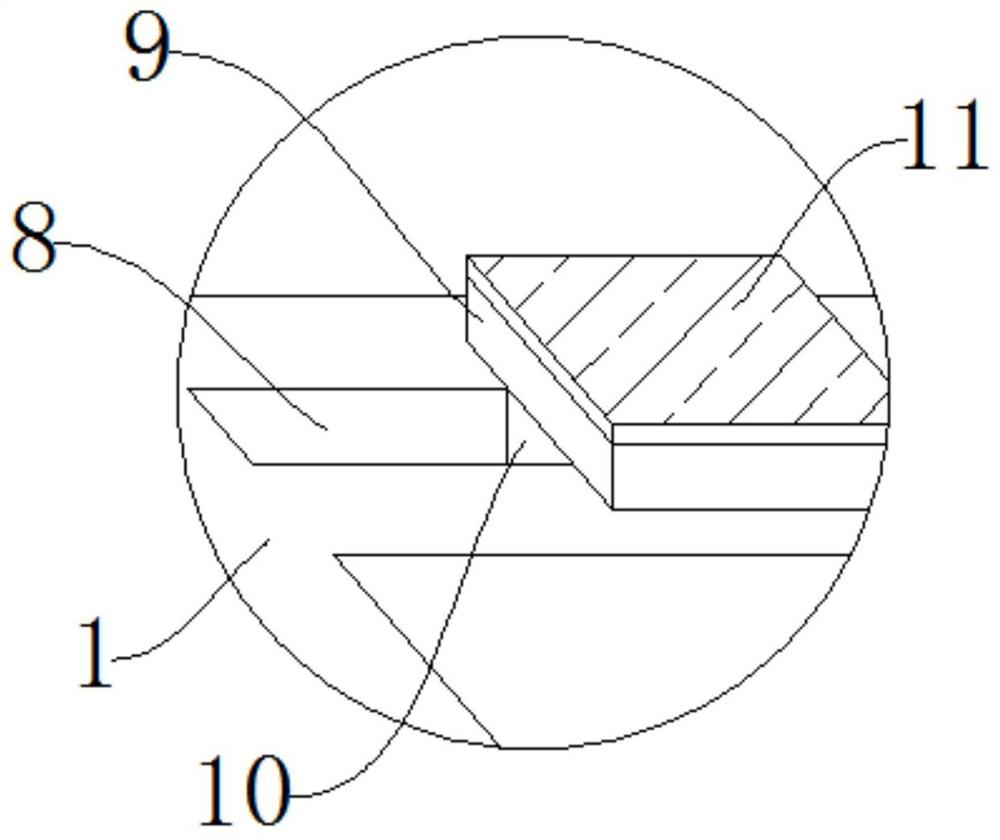

[0038] Such as Figure 1-Figure 4 As shown, an annealing device for a cold-rolled stainless steel processing line includes a box body 1, a PLC controller 5, an electromagnetic heating coil 12 and a circulating water channel 17. An operation panel 2 is arranged on the side wall of the box body 1, and the box body 1 is provided with an operation panel 2. One end of the box body 1 is provided with a box mouth 3, the upper and lower ends of the box body 1 are provided with a cavity 4, the upper end of the box body 1 is provided with the PLC controller 5, and the other end of the box body 1 is provided with a storage tank. Liquid tank 6, the upper end of the liquid storage tank 6 is provided with a water injection valve 7, the inner side walls of the box body 1 are provided with electric slide rails 8, and the upper end of the electric slide rail 8 is provided with a carrier pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com