Hollow glass capable of achieving adjustment of illumination intensities

A light intensity, adjustable technology, applied in the direction of parallel glass structure, window/door improvement, climate change adaptation, etc., can solve the problems that cannot meet the needs of different light intensities, do not have colorful lights, and the hollow glass has a single function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

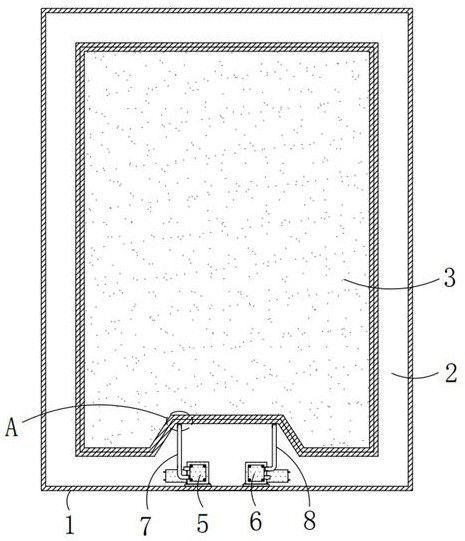

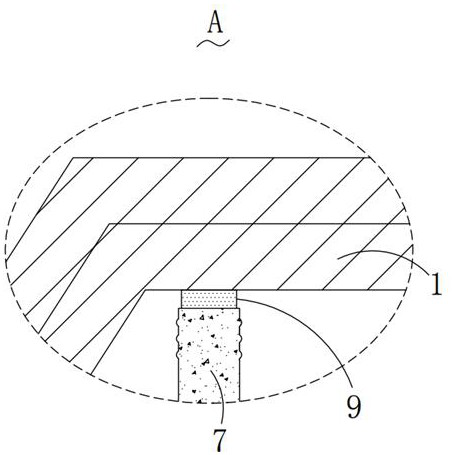

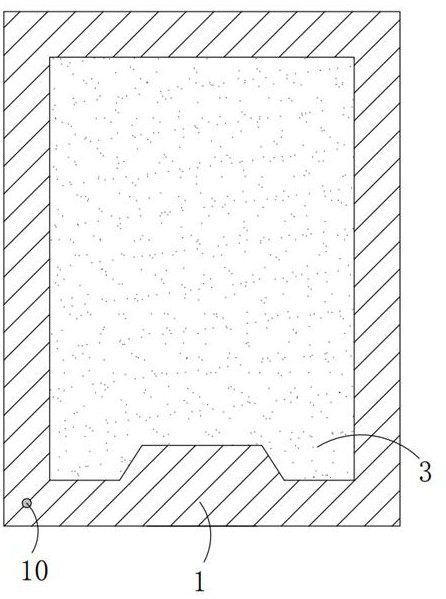

[0031] Please refer to Figure 1-4 , the insulating glass with adjustable light intensity includes: a rectangular frame 1, a chamber 2 is arranged on the rectangular frame 1, and an installation groove is arranged on the inner wall of the rectangular frame 1; a glass layer 3, and the glass layer 3 is sealed and installed In the mounting groove of the rectangular frame 1, the glass layer 3 is provided with a hollow cavity 4; a first vacuum pump 5 and a second vacuum pump 6, and the first vacuum pump 5 and the second vacuum pump 6 are fixedly installed on On the bottom inner wall of the chamber 2, the air inlet of the first vacuum pump 5 and the air outlet of the second vacuum pump 6 are provided with electromagnetic valves; the first installation pipe 7, the first installation pipe 7 Fixedly connected to the air outlet of the first vacuum pump 5; the second installation pipe 8, the second installation pipe 8 is fixedly connected to the air inlet of the second vacuum pump 6; two...

no. 2 example

[0042] Based on the insulating glass with adjustable light intensity provided in the first embodiment of the present application, the second embodiment of the present application proposes another insulating glass with adjustable light intensity. The second embodiment is only a preferred mode of the first embodiment, and the implementation of the second embodiment will not affect the independent implementation of the first embodiment.

[0043] The second embodiment of the present invention will be further described below in conjunction with the drawings and implementation methods.

[0044] Please refer to Figure 5-10, the insulating glass with adjustable light intensity also includes a glare mechanism. After the glare mechanism includes an installation box 11, a colorful light 12 and three adjustment mechanisms, the installation box 11 is fixedly installed in the chamber 2 on the bottom inner wall of the installation box 11, and the top of the installation box 11 is in sealin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com