Heat dissipation structure, electric appliance box and outdoor unit

A technology of heat dissipation structure and electrical box

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

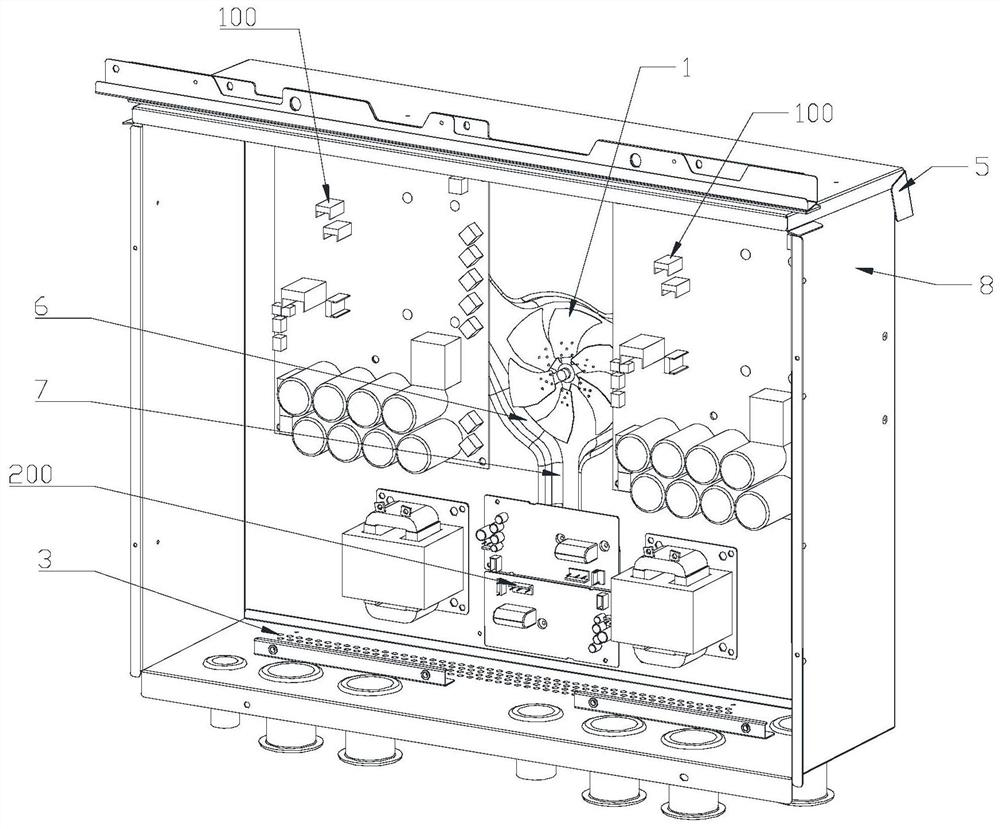

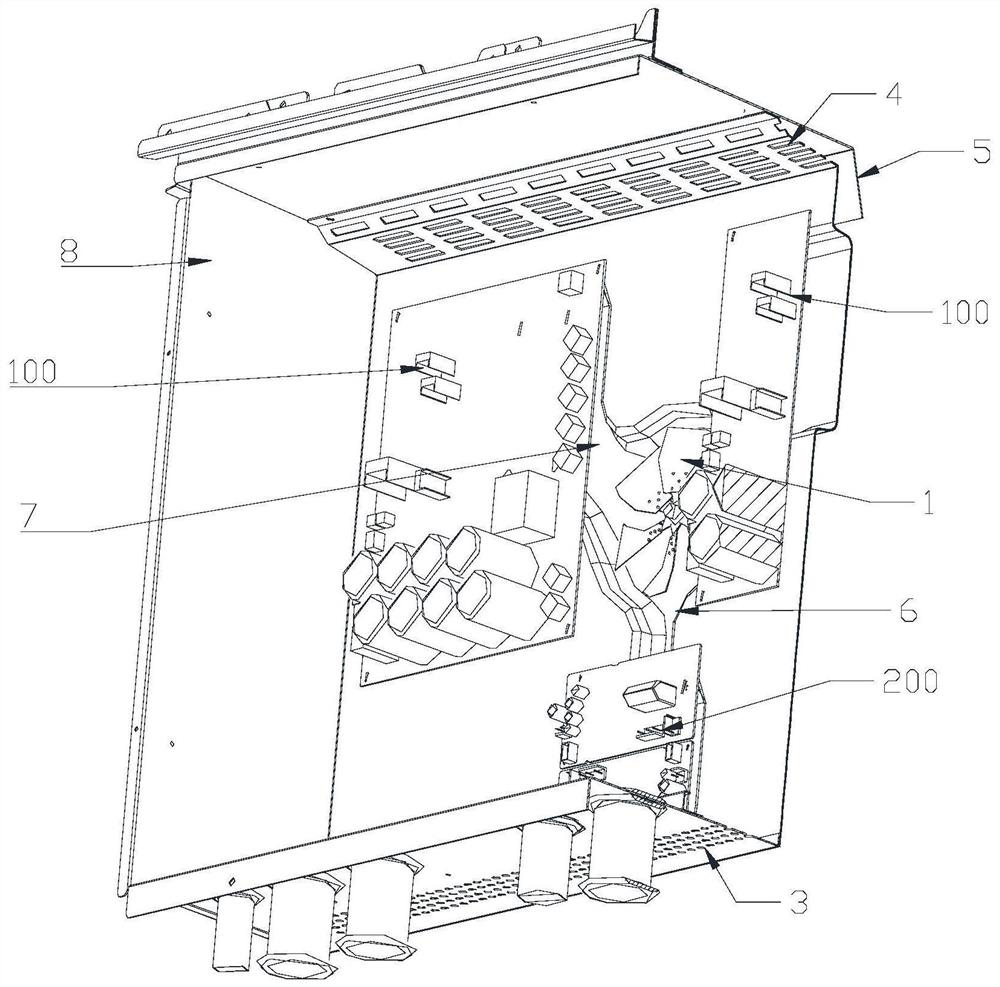

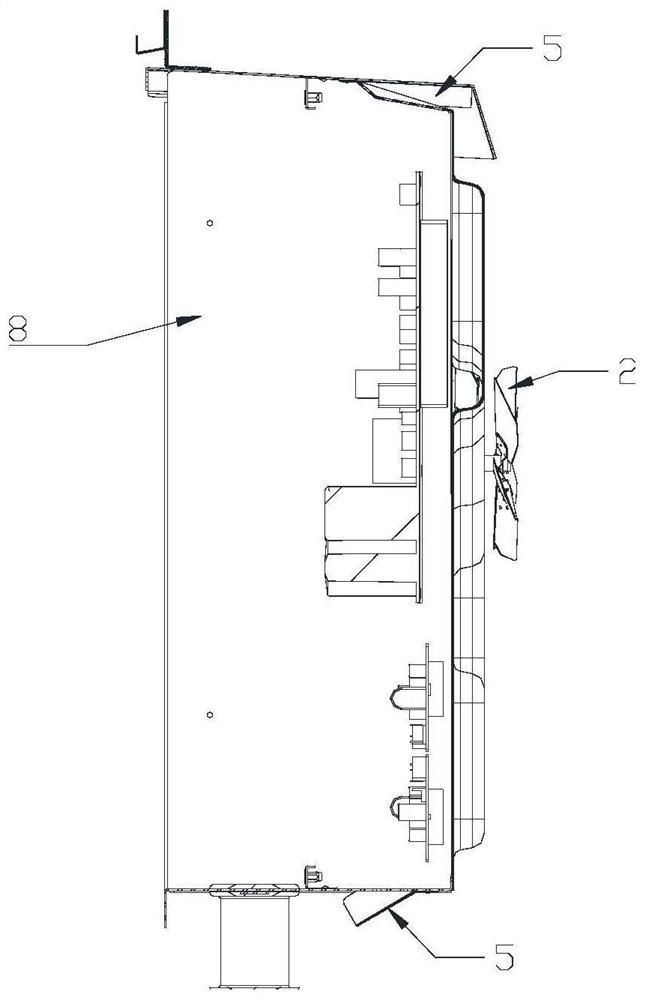

[0029] Such as figure 1 with image 3 As shown, the present invention provides a heat dissipation structure, including a first heat dissipation blade 1 and a second heat dissipation blade 2 respectively arranged inside and outside the electrical box; the second heat dissipation blade 2 is a passive drive structure, and A cooling fan blade 1 is arranged coaxially, and can drive the first cooling fan blade 1 to follow and rotate synchronously.

[0030] It should be noted here that the passive driving referred to herein refers to the driving mode in which the second cooling fan 2 does not require an external power supply.

[0031] Specifically, there are heating elements inside the electrical box, such as the compressor driving board 100 and the fan driving board 200. In order to improve the service life of the equipment, the heating elements are respectively radiated inside and outside the electrical box, thereby improving the heat dissipation effect, and The fan blade cooling...

Embodiment 2

[0033] Such as figure 1 with image 3 As shown, the present invention provides a heat dissipation structure, including a first heat dissipation blade 1 and a second heat dissipation blade 2 respectively arranged inside and outside the electrical box; the second heat dissipation blade 2 is a passive drive structure, and A cooling fan blade 1 is arranged coaxially, and can drive the first cooling fan blade 1 to follow and rotate synchronously.

[0034] It should be noted here that the passive driving referred to herein refers to the driving mode in which the second cooling fan 2 does not require an external power supply.

[0035] Specifically, there are heating elements inside the electrical box, such as the compressor driving board 100 and the fan driving board 200. In order to improve the service life of the equipment, the heating elements are respectively radiated inside and outside the electrical box, thereby improving the heat dissipation effect, and The fan blade heat di...

Embodiment 3

[0040] Such as figure 1 with image 3 As shown, the present invention provides a heat dissipation structure, including a first heat dissipation blade 1 and a second heat dissipation blade 2 respectively arranged inside and outside the electrical box; the second heat dissipation blade 2 is a passive drive structure, and A cooling fan blade 1 is arranged coaxially, and can drive the first cooling fan blade 1 to follow and rotate synchronously.

[0041] It should be noted here that the passive driving referred to herein refers to the driving mode in which the second cooling fan 2 does not require an external power supply.

[0042]Specifically, there are heating elements inside the electrical box, such as the compressor driving board 100 and the fan driving board 200. In order to improve the service life of the equipment, the heating elements are respectively radiated inside and outside the electrical box, thereby improving the heat dissipation effect, and The fan blade cooling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com