Linear module testing platform

A test platform and linear module technology, applied in the direction of program control in measuring devices, instruments, sequence/logic controllers, etc., can solve the problems of single test types and complex test methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

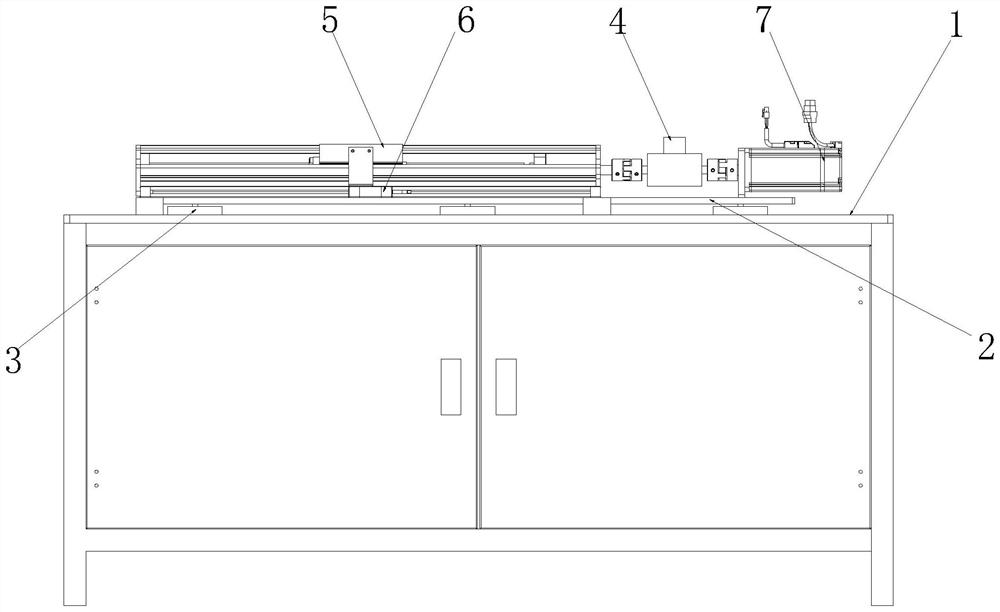

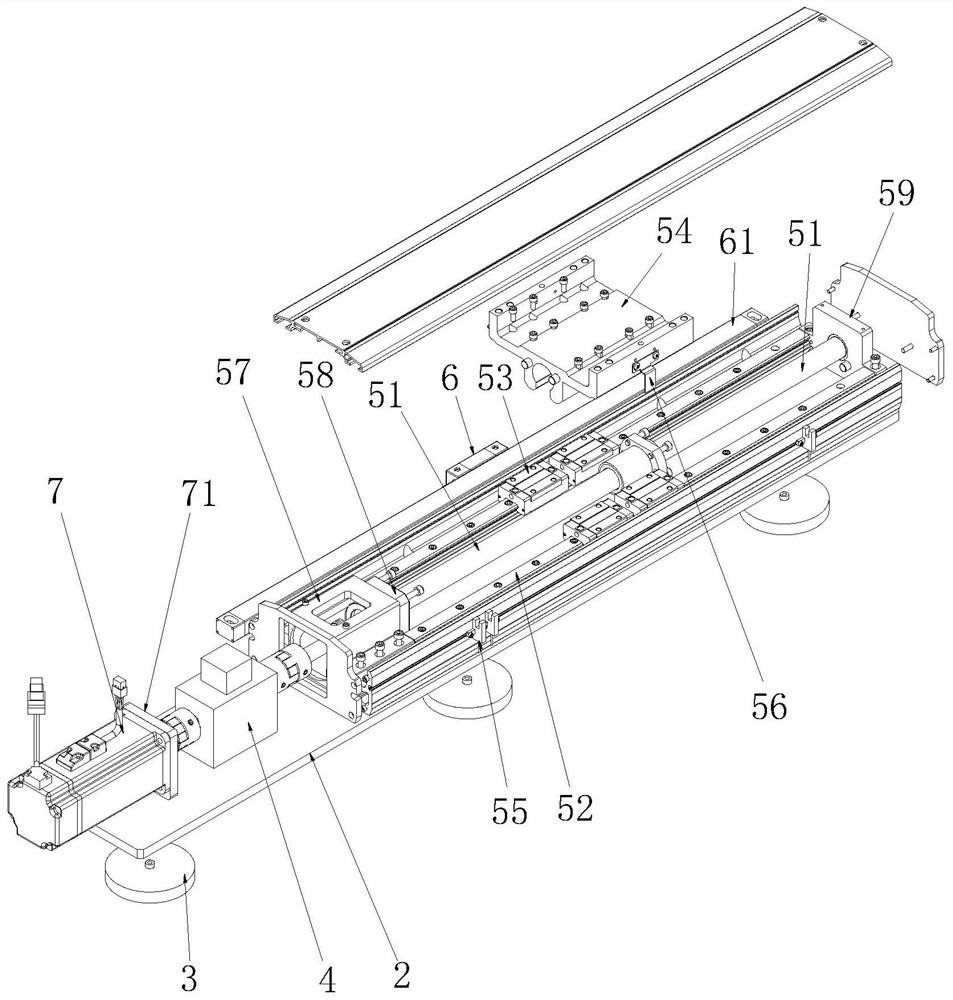

[0025] see Figure 1 to Figure 2 , a linear module test platform provided by the present invention includes a frame 1, a base plate 2 is arranged on the frame 1, the base plate 2 and the frame 1 are connected by several gravity sensors 3, and one end of the base plate 2 is provided with a torque The tester 4 is provided with a module moving seat 5 at the other end, and a grating 6 is arranged on one side of the module moving seat 5 .

[0026] In this embodiment, the module moving seat 5 includes a threaded mandrel 51, the two sides of the threaded mandrel 51 are provided with slide rails 52, and a mobile seat 54 is slidably installed on the slide track 52 through a slider 53, and the mobile seat 54 and the threaded mandrel 51 Connected and driven by screw rod 51.

[0027] Further, on the bottom plate 2, a servo motor 7 is arranged at one end of the torque tester 4, the servo motor 7 is installed on the bottom plate 2 through a motor mounting plate 71, and the power end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com