Power semiconductor device large-current turn-off capability detection device

A technology for power semiconductors and detection equipment, which is applied in the field of high-current turn-off capability detection equipment for power semiconductor devices, and can solve problems that affect the detection accuracy of power semiconductor devices, reduce the detection efficiency of power semiconductor devices, and wires take up a lot of space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

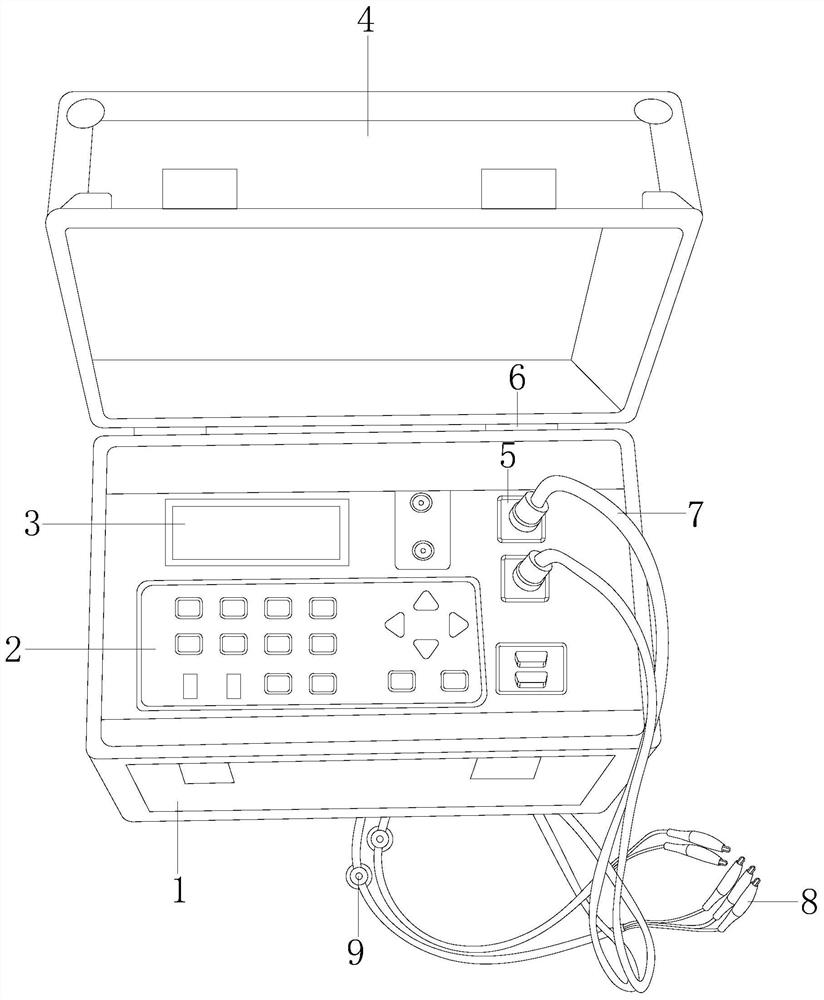

[0030] see figure 1 , the present invention provides a technical solution: a power semiconductor device large current turn-off capability detection equipment, its structure includes a lower box 1, an operation panel 2, a display screen 3, an upper box 4, a socket 5, a hinge 6, Detection wire 7, terminal clip 8, winding device 9, described lower box body 1 is connected with upper box body 4 by hinge 6, and described lower box body 1 is provided with display screen 3, and described display screen 3 is connected with operation The panel 2 is connected by electric wires, and the display screen 3 is provided with a socket 5 on one side, and a detection wire 7 plugged with it is provided on the socket 5, and the detection wire 7 is connected with the terminal clamp 8, The middle position of the detection wire 7 is provided with a winding device 9 connected thereto.

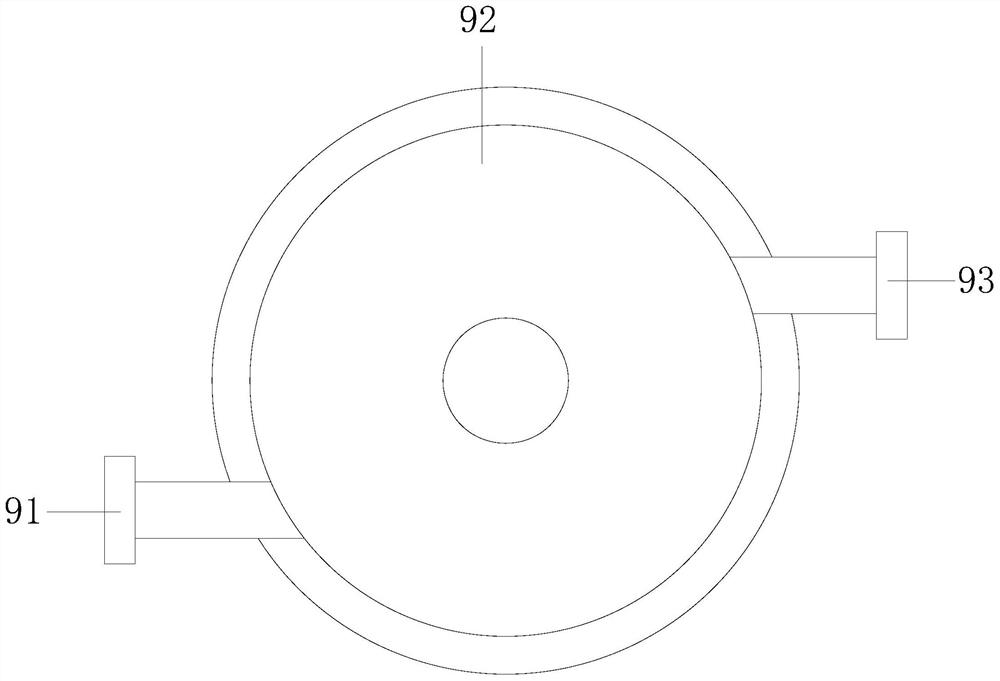

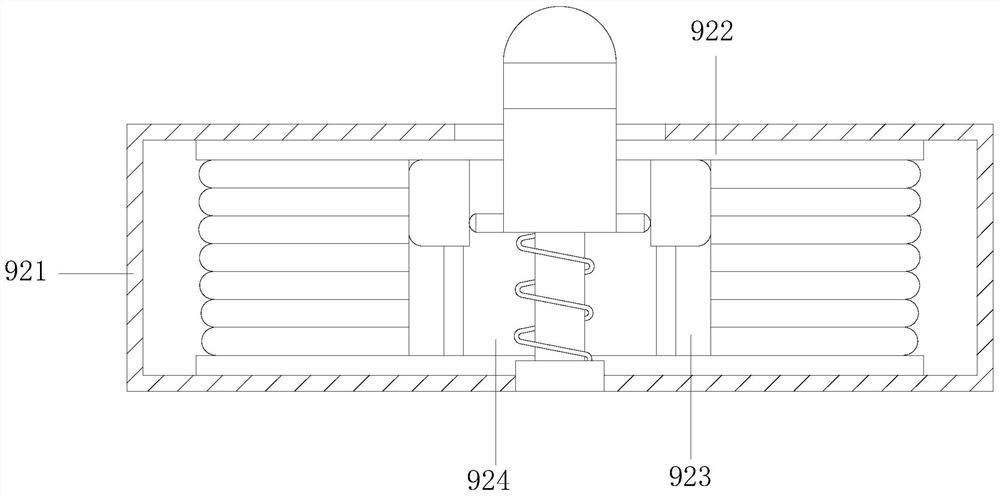

[0031] see figure 2 , the winding device 9 includes a first interface 91, a winding assembly 92, and a second int...

Embodiment 2

[0041] see figure 1 , the present invention provides a technical solution: a power semiconductor device large current turn-off capability detection equipment, its structure includes a lower box 1, an operation panel 2, a display screen 3, an upper box 4, a socket 5, a hinge 6, Detection wire 7, terminal clip 8, winding device 9, described lower box body 1 is connected with upper box body 4 by hinge 6, and described lower box body 1 is provided with display screen 3, and described display screen 3 is connected with operation The panel 2 is connected by electric wires, and the display screen 3 is provided with a socket 5 on one side, and a detection wire 7 plugged with it is provided on the socket 5, and the detection wire 7 is connected with the terminal clamp 8, The middle position of the detection wire 7 is provided with a winding device 9 connected thereto.

[0042] see figure 2 , the winding device 9 includes a first interface 91, a winding assembly 92, and a second int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com