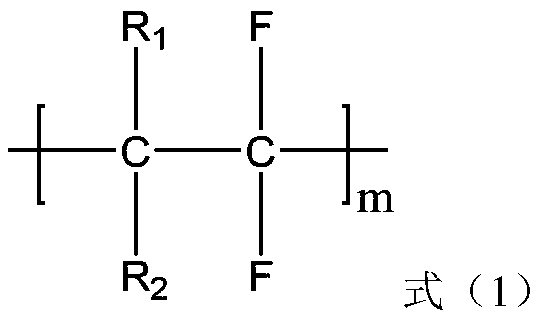

Modified PMMA optical film and preparation method thereof

An optical thin film and modification technology, which is applied in the field of PMMA optical thin film and its preparation, can solve problems such as difficulty in uniform dispersion, slow dissolution rate, and poor flatness of the film.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

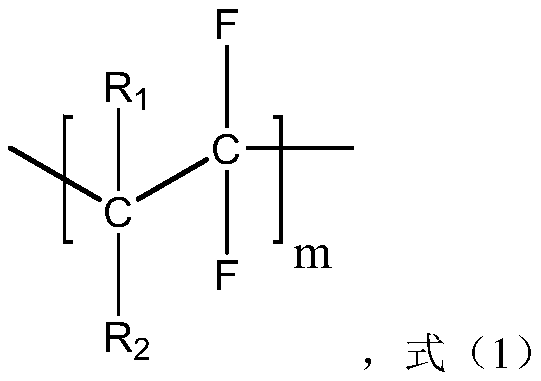

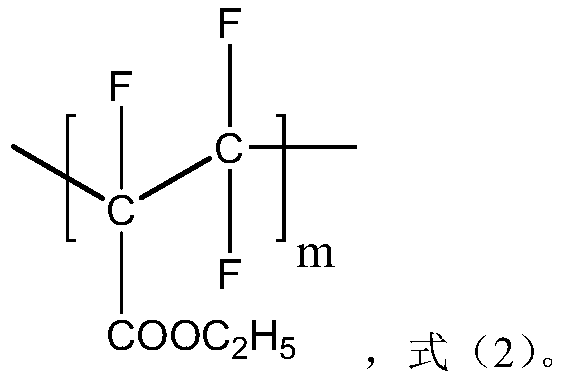

Method used

Image

Examples

Embodiment 1

[0072] (1) Preparation of modified resin

[0073] Modified PMMA resin: 100 parts of PMMA resin, 6 parts of compatibilizer, and 6 parts of leveling agent. Mix the above ingredients in a high-speed mixer at a speed of 150 rpm for 30 seconds, and then fully mix them at a speed of 1100 rpm.

[0074] Modified PC resin: 100 parts of aromatic (co)polycarbonate, 20 parts of compatibilizer, and 3 parts of leveling agent. Mix the above ingredients in a high-speed mixer at a speed of 150rpm for 30s, and then fully mix them at a speed of 1100rpm. mix.

[0075] The aromatic (co)polycarbonate was vacuum-dried in an oven at 120°C for 5 hours before use, and other components were vacuum-dried in an oven at 85°C for 5 hours before use.

[0076] The PMMA resin is Asahi Kasei 80NH with a melt index of 5.5g / 10min (230°C, 2.16kg); the aromatic (co)polycarbonate contains structural unit 1,1-bis(4-hydroxyphenyl)cyclohexyl Alkanes and 3,3',5,5'-tetra-tert-butyl-2,2'-diphenol, melt index is 25g / 10mi...

Embodiment 2

[0110] (1) Preparation of modified resin

[0111] Modified PMMA resin: 100 parts of PMMA resin, 4 parts of compatibilizer, and 4 parts of leveling agent. Mix the above ingredients in a high-speed mixer at a speed of 200 rpm for 30 seconds, and then fully mix them at a speed of 1000 rpm.

[0112] Modified PC resin: 100 parts of aromatic (co)polycarbonate, 18 parts of compatibilizer, 2 parts of leveling agent, mix the above ingredients in a high-speed mixer at a speed of 200rpm for 30s, and then fully mix them at a speed of 1000rpm mix.

[0113] The aromatic (co)polycarbonate was vacuum-dried in an oven at 125°C for 4.5 hours before use, and other components were vacuum-dried in an oven at 85°C for 4.5 hours before use.

[0114] (2) Preparation of modified coating solution

[0115] Modified PMMA resin solution: In a closed reaction container, add 100 parts of dimethylacetamide, under the protection of nitrogen, carry out mechanical stirring at a temperature of 100 ° C, the rot...

Embodiment 3

[0137] (1) Preparation of modified resin

[0138] Modified PMMA resin: 100 parts of PMMA resin, 2 parts of leveling agent, mix the above ingredients in a high-speed mixer at a speed of 50 rpm for 30 seconds, and then fully mix at a speed of 500 rpm.

[0139] Modified PC resin: 100 parts of aromatic (co)polycarbonate, 10 parts of compatibilizer, mix the above components in a high-speed mixer at a speed of 50 rpm for 30 seconds, and then fully mix at a speed of 500 rpm.

[0140]The PMMA resin is LG Chemical HP210 with a melt index of 10g / 10min (230°C, 2.16kg); the aromatic (co)polycarbonate is a compound containing 4,4'-(1,4-phenylene diiso Propyl) homopolymer of diphenol, melt index is 60g / 10min (330 ℃, 2.16kg), weight-average molecular weight Mw=10000g / mol; Described compatibilizer comprises PMMA-g-(St-co-AN) , the mass ratio of PMMA-g-(MAH-co-St) is 1:1, and the composite grafting rate is 5%, St: AN=2:1, MAH: St=0.5:1; The leveling agent is fluorinated polyethylene with a w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com