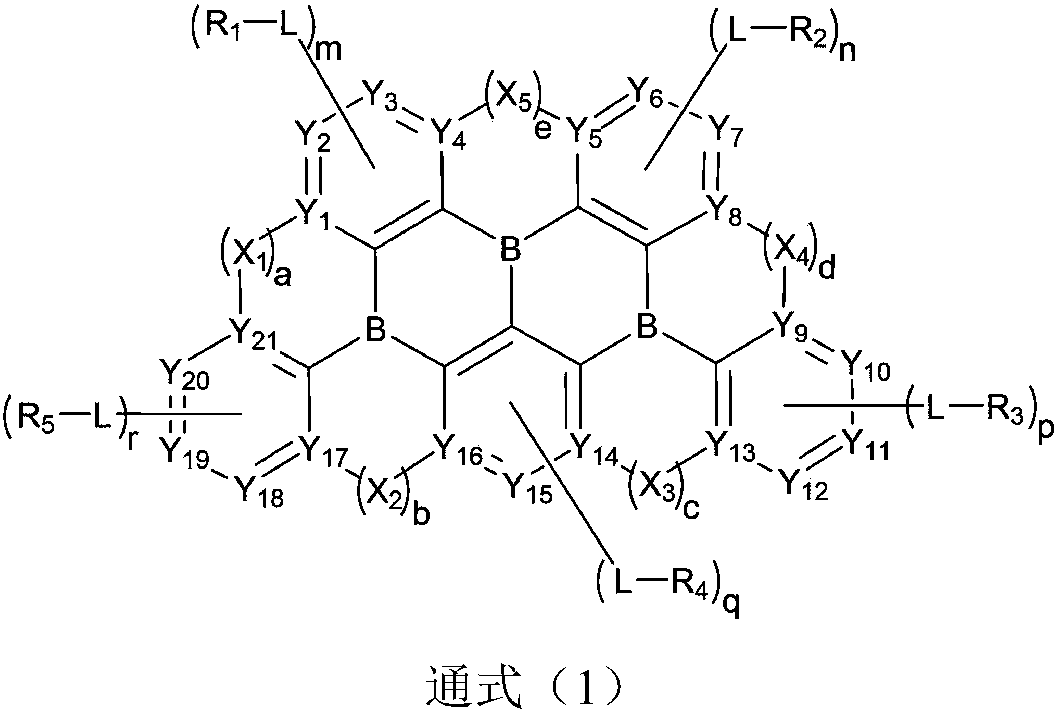

Boron-containing organic compound and application thereof in organic electroluminescent device

A technology of organic compounds and boron compounds, applied in the field of semiconductors, can solve problems such as efficiency roll-off, low S1 state radiation transition rate, difficult exciton utilization rate and high fluorescence radiation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] Embodiment 1: the synthesis of intermediate G:

[0075] Take the synthesis of intermediate G1 as an example:

[0076]

[0077] In a 250mL three-neck flask, under an atmosphere of nitrogen gas, add 0.012mol of raw material A-1, 0.012mol of raw material B-1, and 0.01mol of raw material C-1, dissolve with a mixed solvent (90ml of toluene, 45ml of ethanol), and then add 0.03 mol Na 2 CO 3 aqueous solution (2M), stirred under nitrogen for 1 hour, then added 0.0001mol Pd(PPh 3 ) 4 , heating to reflux for 15 hours, sampling point plate, the reaction is complete. Naturally cooled, filtered, the filtrate was rotary evaporated, and passed through a silica gel column to obtain intermediate G-1 with a purity of 95.9% and a yield of 87.3%. Elemental analysis structure (molecular formula C 56 h 37 B 2 ClN 2 ): theoretical value C, 84.61; H, 4.69; B, 2.72; Cl, 4.46; N, 3.52; test value C, 84.61; ESI-MS (m / z) (M+): theoretical value 794.28, found value 794.13.

[0078] ...

Embodiment 2

[0082] Embodiment 2: the synthesis of compound H2:

[0083]

[0084] (1) Weigh 0.04mol raw material D-1 and 0.025mol raw material E-1, cool down to -78°C; under inert atmosphere, add 0.02mol BCl 3 , heated to 100° C. and refluxed for 48 hours, the reaction was complete, and passed through a silica gel column to obtain intermediate J-1; the HPLC purity was 98.6%, and the yield was 87.2%.

[0085] Elemental analysis structure (molecular formula C 20 h 26 BBr): theoretical value C, 67.26; H, 7.34; B, 3.03; Br, 22.37; found value C, 67.25; H, 7.34; B, 3.03; Br, 22.38. ESI-MS(m / z)(M + ): The theoretical value is 356.13, and the measured value is 356.23.

[0086] (2) In a 250mL three-neck flask, under a nitrogen atmosphere, add 0.01mol of intermediate J-1, 0.015mol of raw material F-1, dissolve in a mixed solvent (90ml of toluene, 45ml of ethanol), and then add 0.03mol of Na 2 CO 3 aqueous solution (2M), stirred under nitrogen for 1 hour, then added 0.0001mol Pd(PPh 3 ) 4...

Embodiment 3

[0089] Embodiment 3: the synthesis of compound H11:

[0090]

[0091] Take 0.1mol of intermediate G-1, add 0.12mol of tert-butyllithium, 120ml of tert-butylbenzene, keep warm at 60°C for 2 hours, cool down to room temperature, add dropwise 0.12mol of BBr 3 After fully reacting for half an hour, water was added to precipitate a solid, which was washed with n-hexane in sequence and recrystallized with ethanol to obtain compound H11. HPLC purity 97.3%, yield 82.1%.

[0092] Elemental analysis structure (molecular formula C 56 h 35 B 3 N 2 ): theoretical value C, 87.54; H, 4.59; B, 4.22; N, 3.65; test value C, 87.54; H, 4.58; B, 4.22; N, 3.66. ESI-MS(m / z)(M + ): The theoretical value is 768.31, and the measured value is 768.28.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com