Buoy type dirt-blocking float-guiding device

A buoy-type and buoy technology, which is applied in the field of sewage blocking and drift-guiding devices for water intake holes in water conservancy and hydropower projects, can solve problems such as easy breaking, and achieve the effects of long service life, reliable connection and excellent working performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

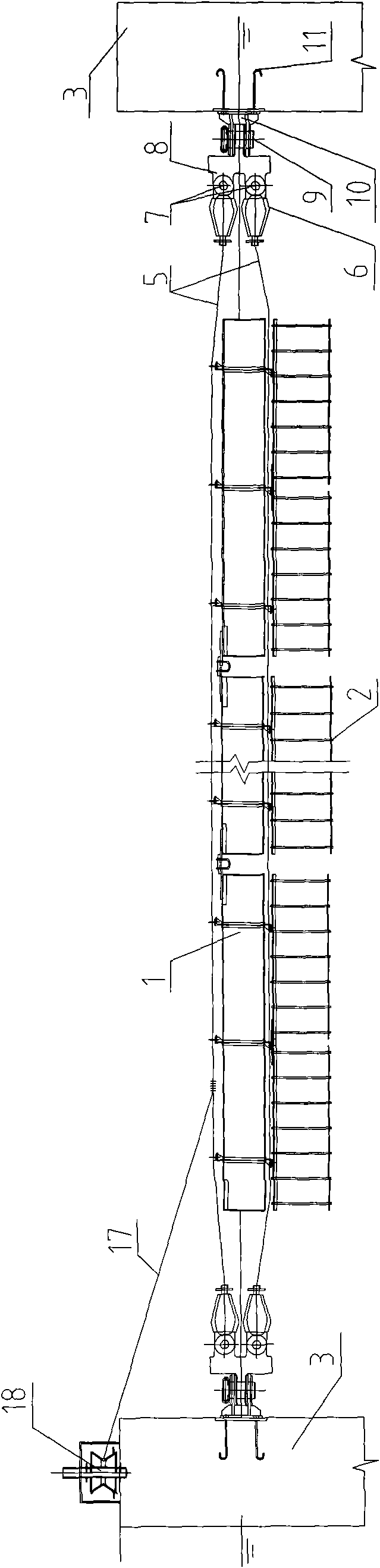

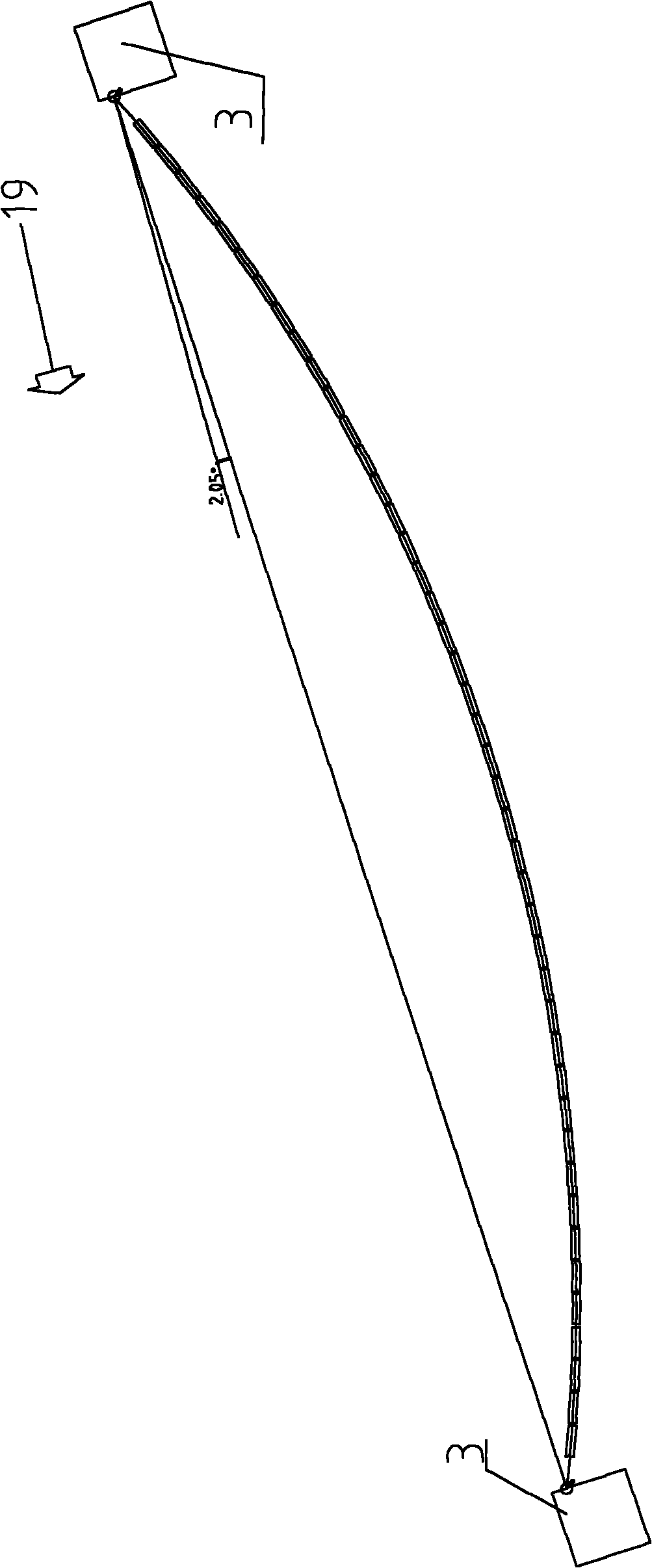

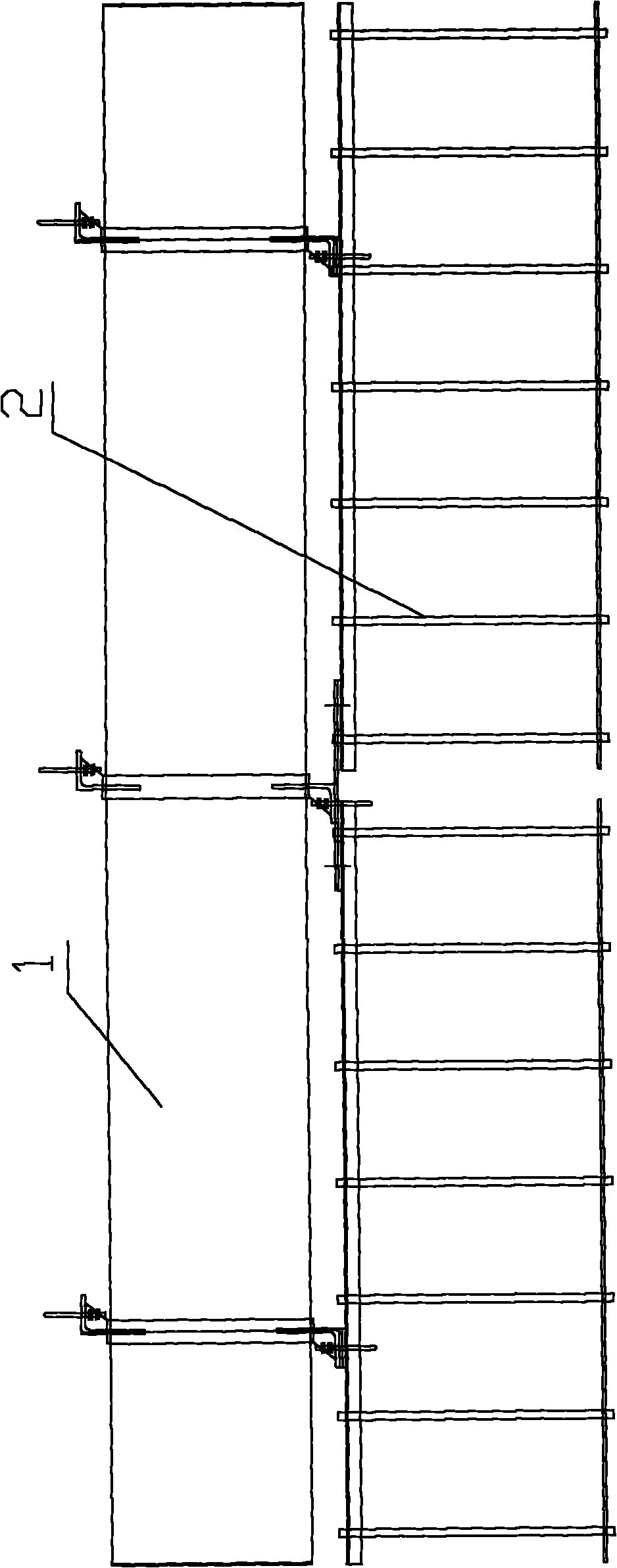

[0039] Refer to the attached Figure 1-5 , the present invention includes a buoy assembly 1, a hanging grid 2 arranged below the buoy assembly 1, a plurality of buoy assemblies 1 are connected as a whole and connected with an anchor foundation 3 provided on a bank or a dam body, and the upper and lower parts of the buoy assembly 1 are respectively Hanging lugs 4 are set, and suspension cables 5 are set in the lifting lugs 4. The two ends of the suspension cables 5 are connected to the anchor foundation 3 through the end connection devices. on the water. The end connecting device may be a wheel carrier in the prior art.

Embodiment 2

[0041] Refer to the attached Figure 1-13 , the present invention includes a buoy assembly 1, a hanging grid 2 arranged below the buoy assembly 1, a plurality of buoy assemblies 1 are connected as a whole and connected with an anchor foundation 3 provided on a bank or a dam body, and the upper and lower parts of the buoy assembly 1 are respectively Hanging lugs 4 are set, and suspension cables 5 are set in the lifting lugs 4. The two ends of the suspension cables 5 are connected to the anchor foundation 3 through the end connection devices. on the water. The end connection device includes a tapered sleeve 6 fixedly connected with the suspension cable 5, a cross hinge rod 8 connected with the tapered sleeve 6 through the first hinge shaft 7, and a cross hinge rod 8 connected with the cross hinge rod 8 through the second hinge The hinge base 10 connected with the shaft 9, and the embedded anchor 11 fixedly connected with the hinge base 10, the embedded anchor 11 is embedded in ...

Embodiment 3

[0043] On the basis of Embodiment 2, the first hinge axis 7 is arranged in a horizontal direction, and the second hinge axis 9 is arranged in a vertical direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com