A helical waveguide grating assisted reverse coupler type optical dispersion delay line

A reverse coupler and helicon wave technology, applied in the field of optical communication, can solve the problems of increasing system complexity, increasing integration difficulty, unfavorable miniaturization, etc., achieving low transmission loss, low insertion loss, and suppression of output spectral side lobes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

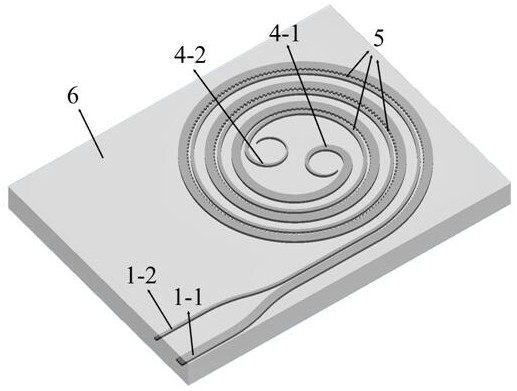

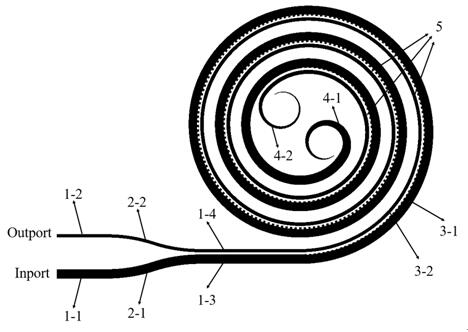

[0020] Embodiment 1: see figure 1 , a helical waveguide grating assisted reverse coupler type optical dispersion delay line, including SiO 2 Cladding 6, SiO 2There is a waveguide layer arranged horizontally inside the cladding, and the waveguide layer is made of Si material, including four transverse straight waveguides, namely the first straight waveguide 1-1, the second straight waveguide 1-2, and the third straight waveguide 1 -3. The fourth straight waveguide 1-4, two S-shaped curved waveguides, that is, the first S-shaped curved waveguide 2-1, the second S-shaped curved waveguide 2-2, two sections of spiral loss lines, that is, the first spiral loss line 4 -1. The second helical loss line 4-2, and a section of helical waveguide chirped grating assisted reverse coupler; where a transverse wide straight waveguide on the left is used as the input end of the reverse coupler, and a transverse narrow straight waveguide is used as the reverse coupling The two ports are connect...

Embodiment 2

[0021] Embodiment 2: refer to figure 1 — Figure 4 ,Such as figure 1 and figure 2 As shown, the present invention designs a spiral waveguide grating assisted reverse coupler type optical dispersion delay line, and its waveguide layer is embedded in SiO 2 The strip-shaped Si waveguide in the cladding 6 includes a first straight waveguide 1-1, a second straight waveguide 1-2, a first S-shaped curved waveguide 2-1, a second S-shaped curved waveguide 2-2, and a first spiral Loss line 4-1, second helical loss line 4-2 and helical waveguide chirped grating assisted reverse coupler 5. The left ends of the first straight waveguide 1-1 and the second straight waveguide 1-2 are respectively the input port (Inport) and the output port (Outport) of the dispersion delay line; the third straight waveguide 1-3 and the fourth straight waveguide 1 -4 is used as a pre-buffer, the right end is respectively connected to the left end of the spiral single-side wall modulation waveguide grating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com