Wire clamping device and winding machine

A wire clamping and winding technology, which is applied in coil manufacturing and other directions, can solve problems such as enameled wire stuck, equipment failure, and difficult to control the gap between the wire sleeve and the wire post.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

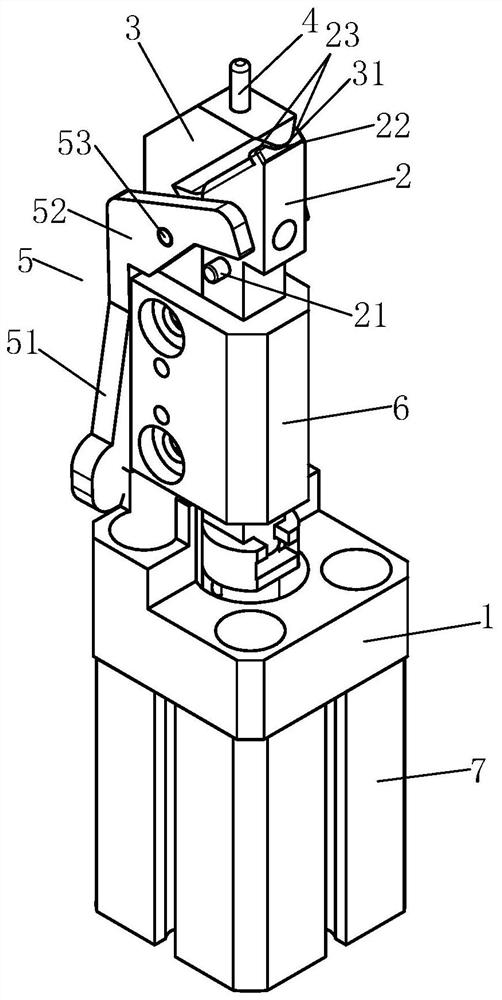

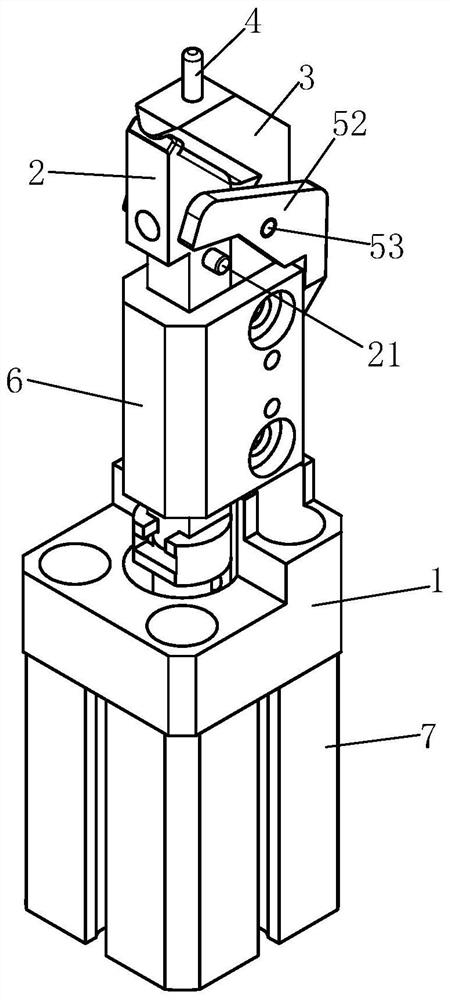

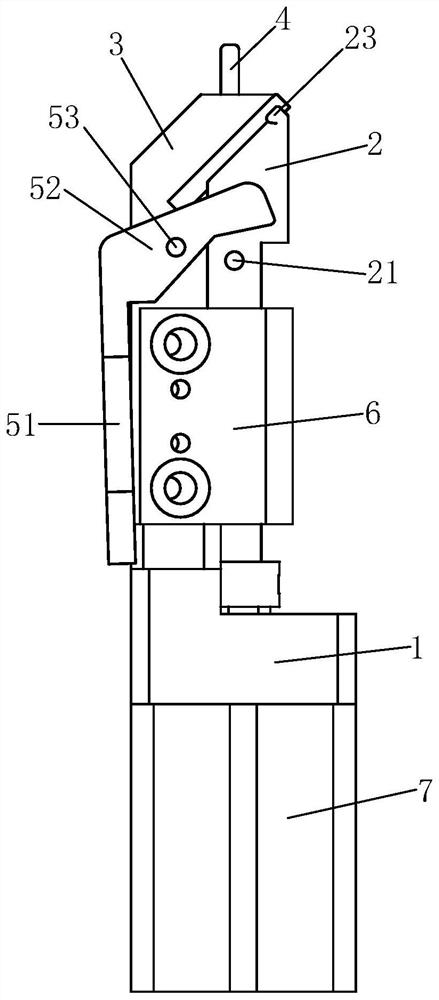

[0027] Examples, see Figure 1-Figure 5 As shown, a wire clamping device of the present invention includes a mounting base 1, a wire clamp and a driving mechanism. The wire clamp includes a movable clamping finger 2 and a fixed clamping finger 3 arranged on the mounting base 1. and connect the movable clamp finger 2 to drive the movable clamp finger 2 to close or separate from the fixed clamp finger 3; it also includes a winding column 4, which is arranged on the movable clamp finger 2, and the winding column 4 Through the fixed clip finger 3, as the movable clip finger 2 and the fixed clip finger 3 are closed, the winding part of the winding column 4 is exposed outside the fixed clip finger 3, and as the movable clip finger 2 and the fixed clip finger 3 are separated, The thread winding part of the thread winding post 4 is in an off-line state received in the fixed finger 3, so that there is no need to use an off-line mechanism to assist in off-line. The thread winding part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com