Food sterilization device

A technology for sterilization equipment and food, which is applied in the field of food processing, and can solve the problems of height adjustment of racks and inability to use racks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

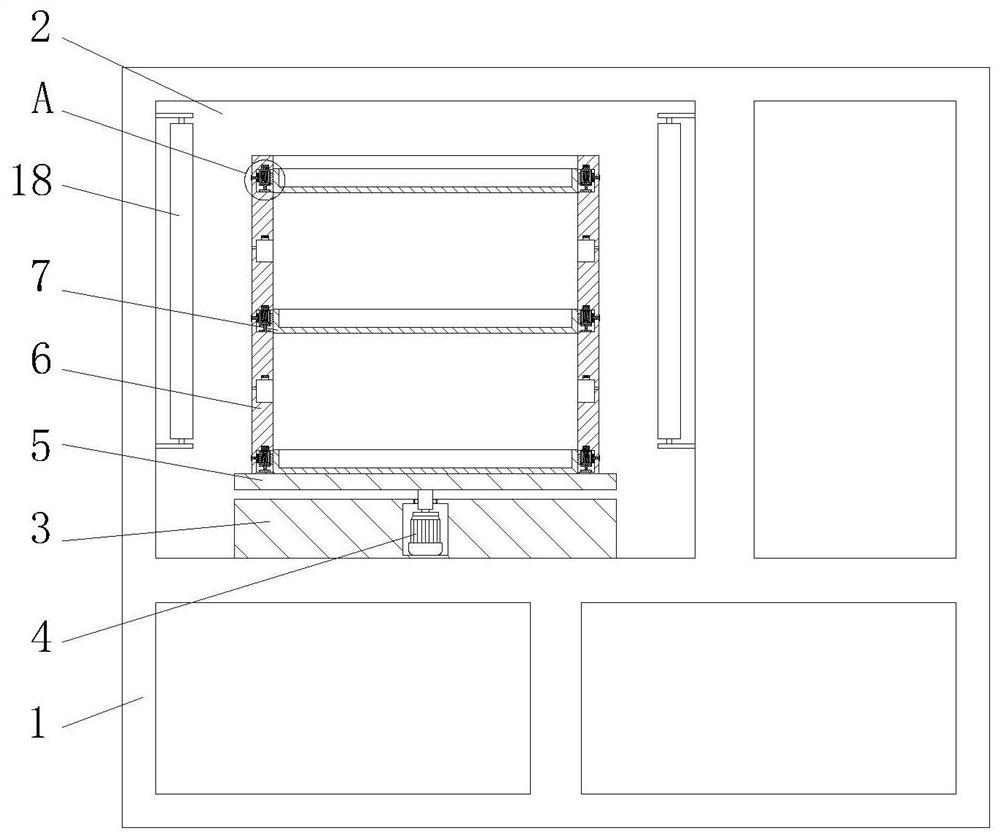

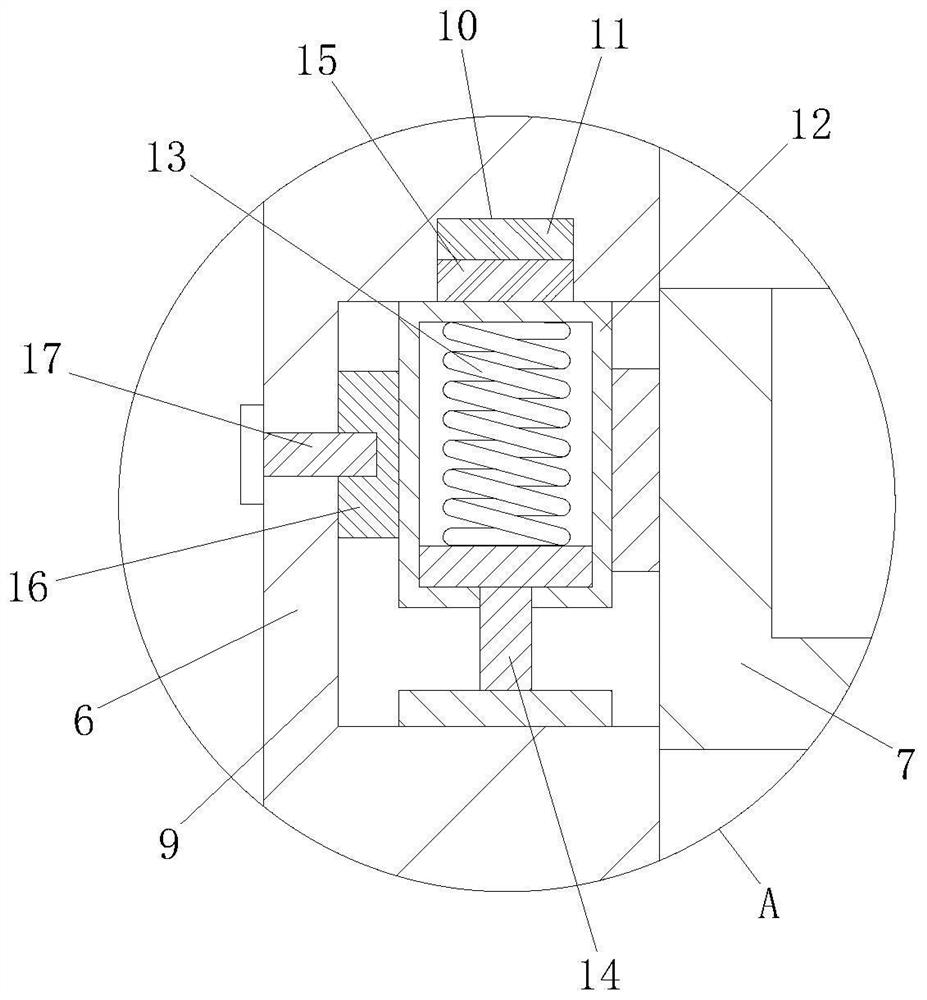

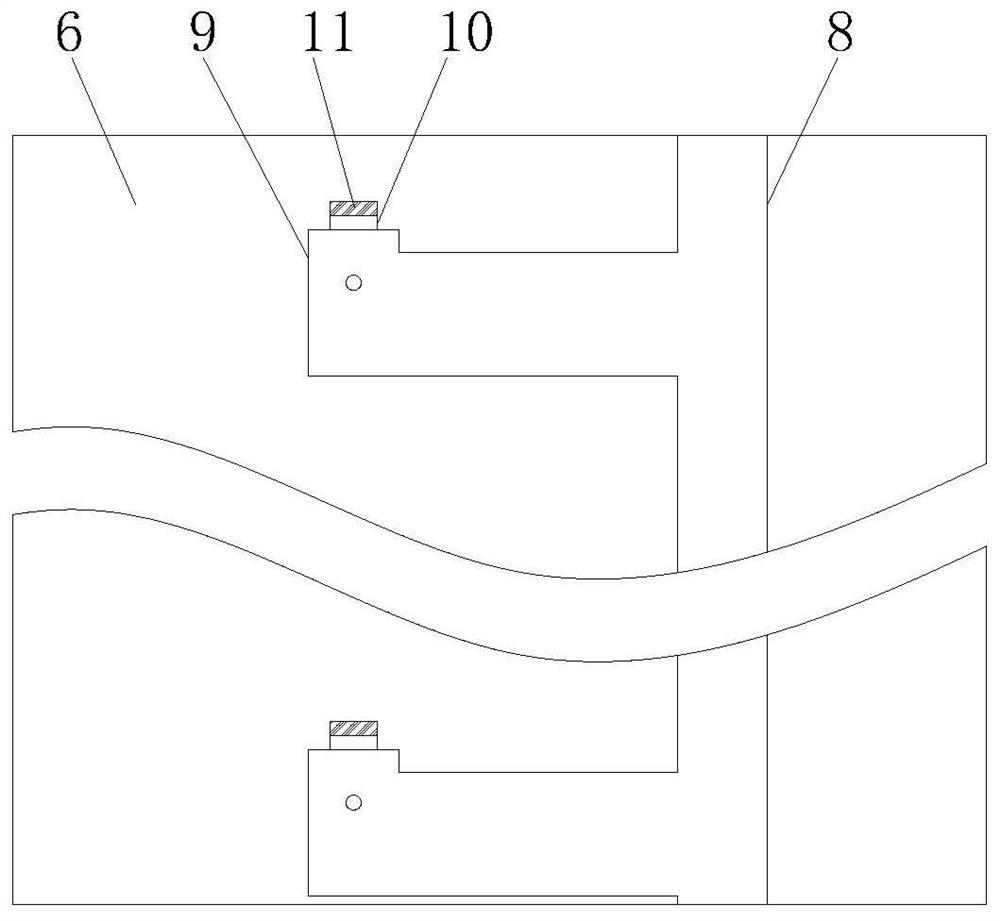

[0028] see Figure 1-7 As shown, a food sterilization equipment includes a sterilization box 1, a sterilization chamber 2 is arranged in the sterilization box 1, a workbench 3 is fixedly connected to the bottom end surface of the sterilization chamber 2, and the workbench 3. It is connected with the mounting base 5 through a rotating assembly, and both sides of the top of the mounting base 5 are fixedly connected with an arc-shaped support plate 6, and the arc-shaped support plate 6 is provided with a vertical slide groove 8, and the vertical slide One side of the groove 8 is evenly provided with a plurality of connection grooves, and the side of the connection groove away from the vertical chute 8 is provided with a fixed groove 9, and a placement plate 7 is arranged between the two arc-shaped support plates 6, so that Both end faces of the placement plate 7 are fixedly connected to the limit sleeve 12 through a support block, and the limit sleeve 12 is adapted to the vertica...

Embodiment 2

[0037] see Figure 8 As shown, Comparative Example 1 is another embodiment of the present invention; the top end surface of the workbench 3 is provided with an annular groove 30, and both sides of the bottom end surface of the mounting seat 5 are fixedly connected with support blocks 31, The support block 31 is slidingly connected with the annular groove 30, and balls are installed on the bottom of the support block 31, and the balls are fitted with the annular groove 30; The sliding fit between the grooves 30 facilitates the auxiliary support for the rotation of the mounting seat 5. The balls provided at the bottom of the support block 31 reduce the friction between the support block 31 and the annular groove 30, avoiding the friction between the support block 31 and the annular groove 30. 31 wear, prolonging the service life of the support.

[0038] Working principle, when the staff needs to place food of different volumes, slide the placement plate 7 along the vertical chu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com