Stapler nail cartridge anti-drop mechanism

A technology of anti-dropping and staplers, applied in the field of staplers, can solve problems such as insufficient suturing at the suture site, tissue injury, and hidden dangers to the patient's health, and achieve the effect of fixing and fastening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

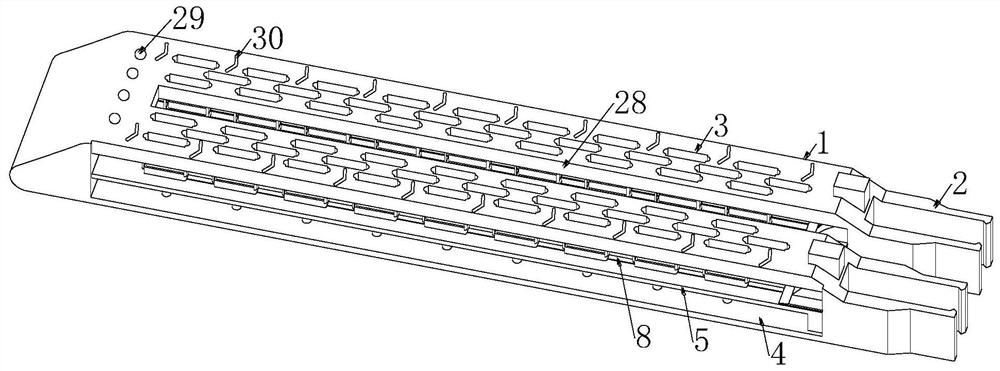

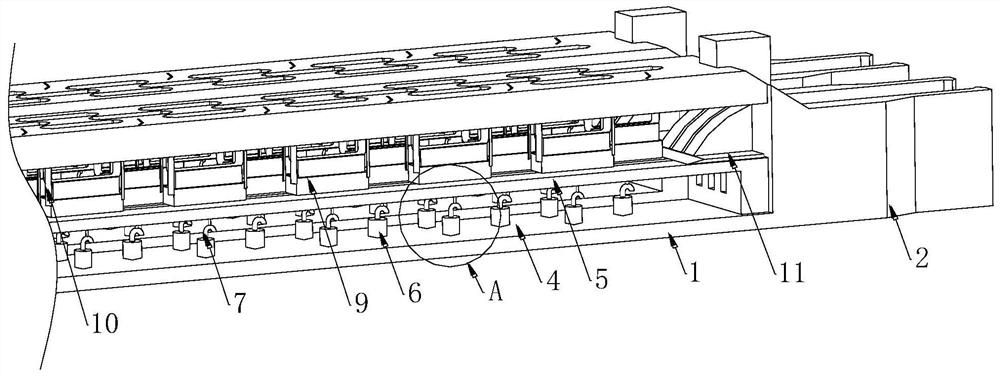

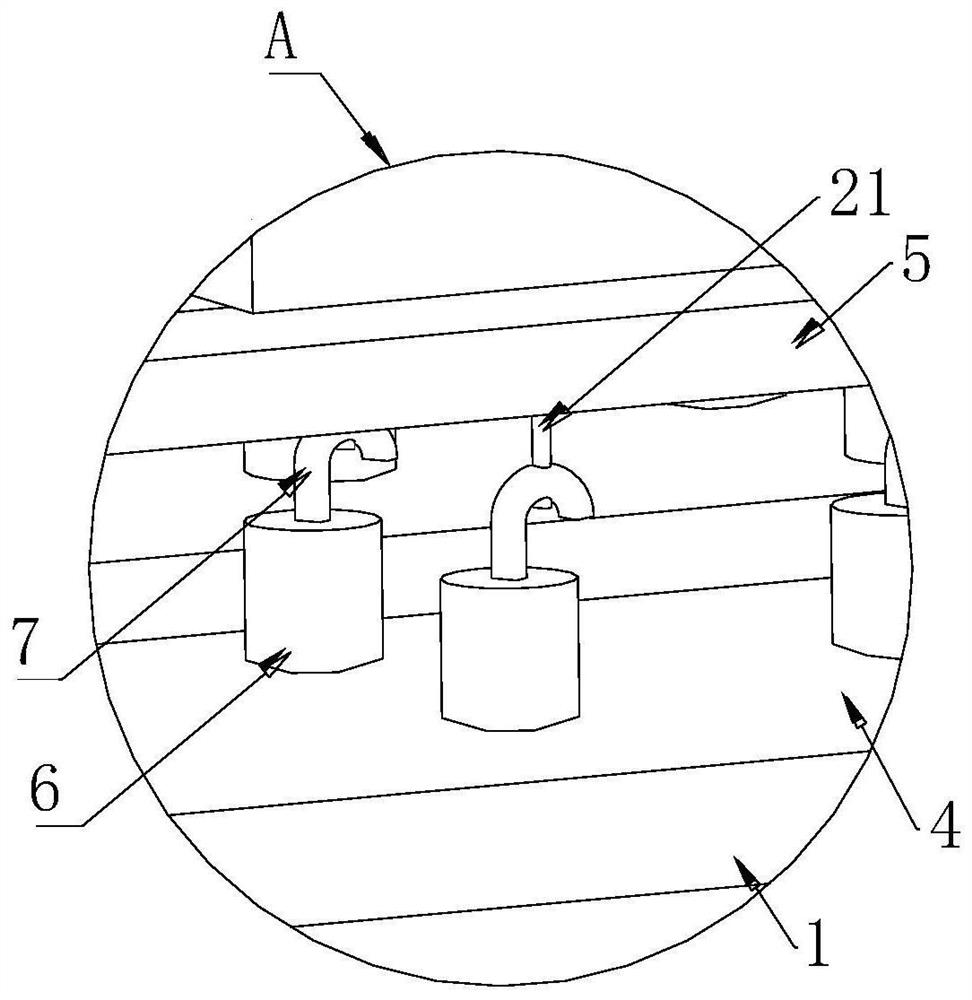

Embodiment 1

[0035] see Figure 1-9 , a nail-pressing anti-drop mechanism for stapler cartridges, comprising a staple cartridge 1, two sets of posts 2 are fixedly connected to the right side of the staple cartridge 1, and evenly distributed nails are provided on the top of the staple cartridge 1 close to the front and rear sides. Groove 3, the middle position of the top of the nail bin 1 is provided with a pusher groove 28, the interior of the nail bin 1 is provided with two symmetrical inner grooves 4, the inner wall of the inner groove 4 is fixedly connected with a partition plate 5, and the inner wall of the bottom side of the inner groove 4 is connected to the The corresponding position of the nail groove 3 is fixedly connected with an evenly distributed internal thread column 6, and the internal thread of the internal thread column 6 is connected with a threaded hook 7. The top of the partition plate 5 is provided with three evenly distributed moving grooves 8, and the partition plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com