An air flotation garbage winnowing machine

A winnowing machine and air flotation technology, which is applied to the separation of solids from solids by air flow, solid separation, chemical instruments and methods, etc., can solve the problems of short winnowing process, waste of resources, and light garbage , to achieve the effects of improving screening accuracy, promoting tumbling, and prolonging winnowing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

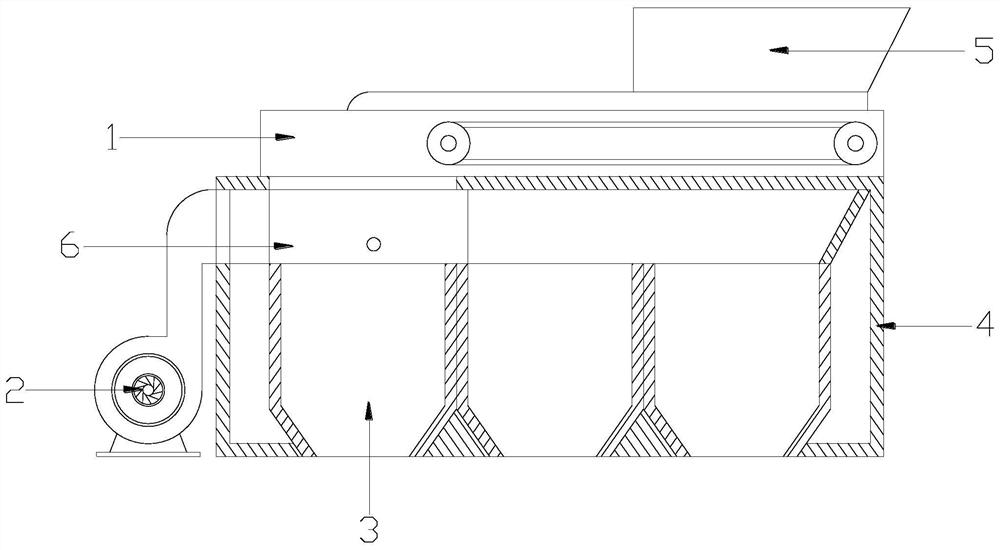

[0028] see Figure 1-Figure 5 , the present invention provides an air flotation type garbage winnowing machine, its structure includes a belt conveyor 1, a driving fan 2, a garbage storage box 3, a winnowing machine main body 4, a garbage feeding hopper 5, and a separation mechanism 6. The main body 4 of the winnowing machine is placed horizontally on the ground, and the three garbage storage boxes 3 are respectively vertically nested inside the main body 4 of the winnowing machine from left to right, and the driving fan 2 is located in the main body of the winnowing machine 4 on the left side and communicates with the air separator main body 4, the belt conveyor 1 is horizontally installed on the top of the air separator main body 4, the garbage feeding hopper 5 is installed on the right end of the upper surface of the belt conveyor 1, and the separation mechanism 6 is installed on the top of the air separator main body 4, and is located above the leftmost garbage storage box...

Embodiment 2

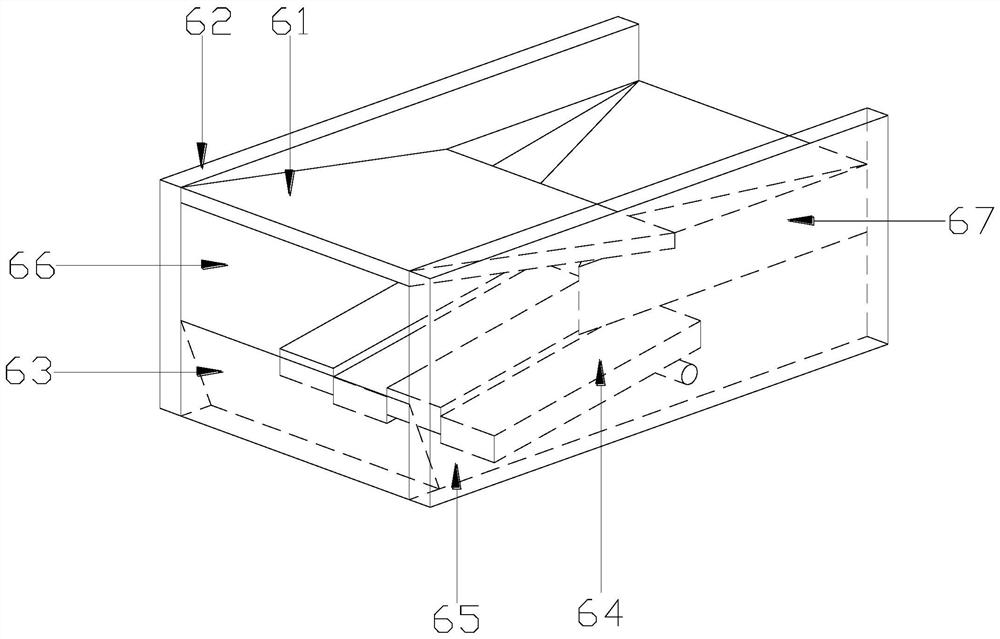

[0031] see Figure 6-Figure 8 , the separation mechanism 6 further includes a diversion conveying device 67 , and the diversion conveying device 67 is nested in the fixed side plate 62 and is located on the right side of the first deflector 61 .

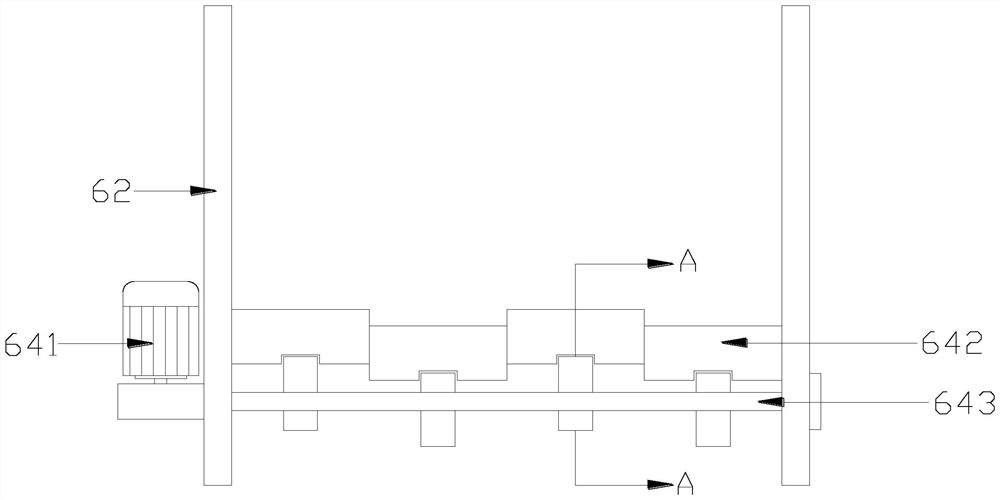

[0032] As a further improvement of the present invention, the diversion conveying device 67 is composed of a second deflector 671, a conveyer main body 672, a conveying inlet 673, a conveying outlet 674, and a traction device 675, and the conveyer main body 672 is nested on the fixed side Inside the plate 62 and on the right side of the first deflector 61, the top of the conveyor main body 672 is provided with a second deflector 671, and the delivery inlet 673 is provided with two and connected through the left side of the conveyor main body 672 and Located at both ends of the second deflector 671 , the delivery outlet 674 is connected to the right end of the conveyor main body 672 with a closed window and communicates with the deliv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com