Vehicle frame wire harness modular design method, device and system and storage medium

A modular design and wiring harness technology, which is applied to vehicle components, transportation and packaging, circuits or fluid pipelines, etc., can solve the problems of complex wiring harness design, poor versatility, and non-universal wiring harnesses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

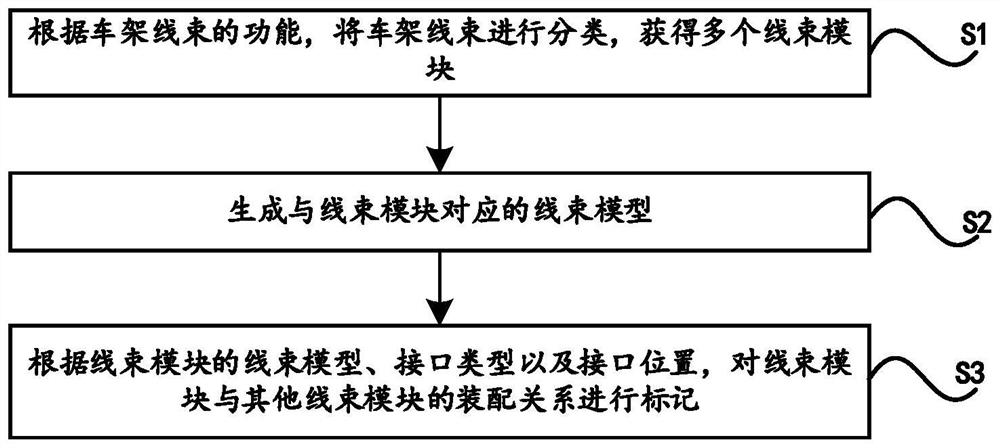

Method used

Image

Examples

Embodiment

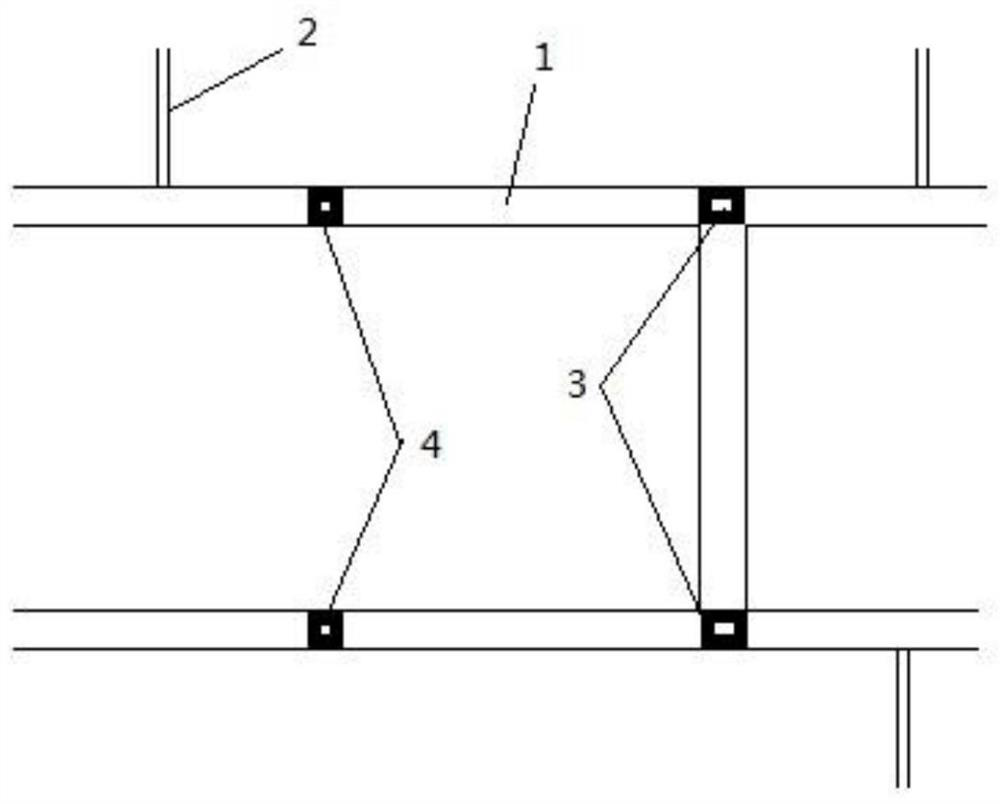

[0075] Frame wiring harness module, including main wiring harness branch 1, several branch wiring harnesses 2 and several functional wiring harnesses;

[0076] The basic line module 1 is arranged in the shape of "I", and the other line modules 2 are connected to the main wiring harness. The two points intersecting on the "I" shape, that is, the positioning color mark in front of the second beam, are used as the first positioning point 3 (the color mark of the wiring harness, Refer to the position of the first pipeline support in front of the second crossbeam as shown in the reference positioning point), and take a certain distance to the left of the first positioning point 3 as the second positioning point 4 (the position of the first pipeline support behind the long round holes on the left and right sides), and the wiring harness of each module includes The main wiring harness and at least one branch wiring harness. The main wiring harnesses of all module wiring harnesses are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com