Bionic airplane wheel chock

A wheel block and aircraft technology, applied in the field of aircraft wheel blocks, can solve the problems of large aircraft thrust, inability to maintain stable parking of the aircraft, and poor blocking effect of wheel blocks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

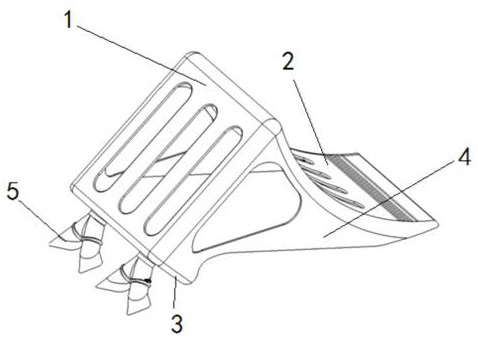

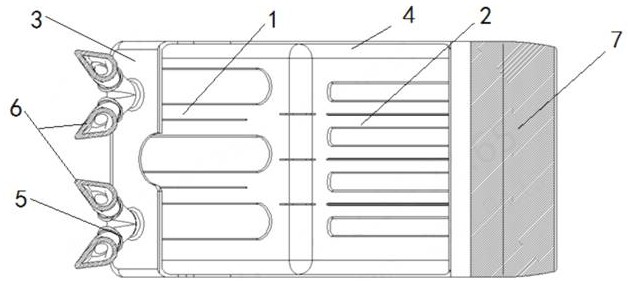

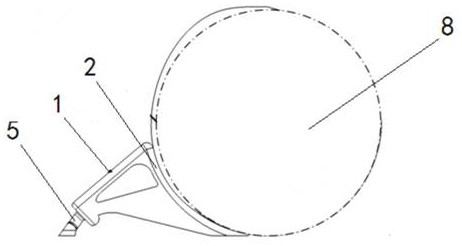

[0024] Referring to the accompanying drawings, the bionic aircraft wheel chock of the present application includes a wheel chock body and a supporting foot, and the wheel chock body is a triangular shape, including a front baffle 1, a rear baffle 2, two symmetrical side panels 4 and a front The base plate 3 and the outer profile of the rear baffle 2 are matched with the aircraft wheel 8. In practice, the rear baffle 2 is a curved surface structure, and the radius of the curved surface is preferably greater than the radius of the aircraft tire 8, so that the aircraft tire 8 is still in contact with the aircraft wheel after elastic deformation. The bezel fits snugly. Protruding transverse anti-slip strips are respectively provided on the upper end and the lower end of the surface of the tailgate. The bottom of the lower end of the rear baffle 2 is the rear support surface 7 of the wheel chock body, the support foot 5 is located at the front lower side of the wheel chock body, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com