Energy-saving and environment-friendly compression block forming equipment for garbage treatment

A technology of garbage disposal, energy saving and environmental protection, applied in the field of compression equipment, can solve the problems of low degree of automation, low work efficiency, simple structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

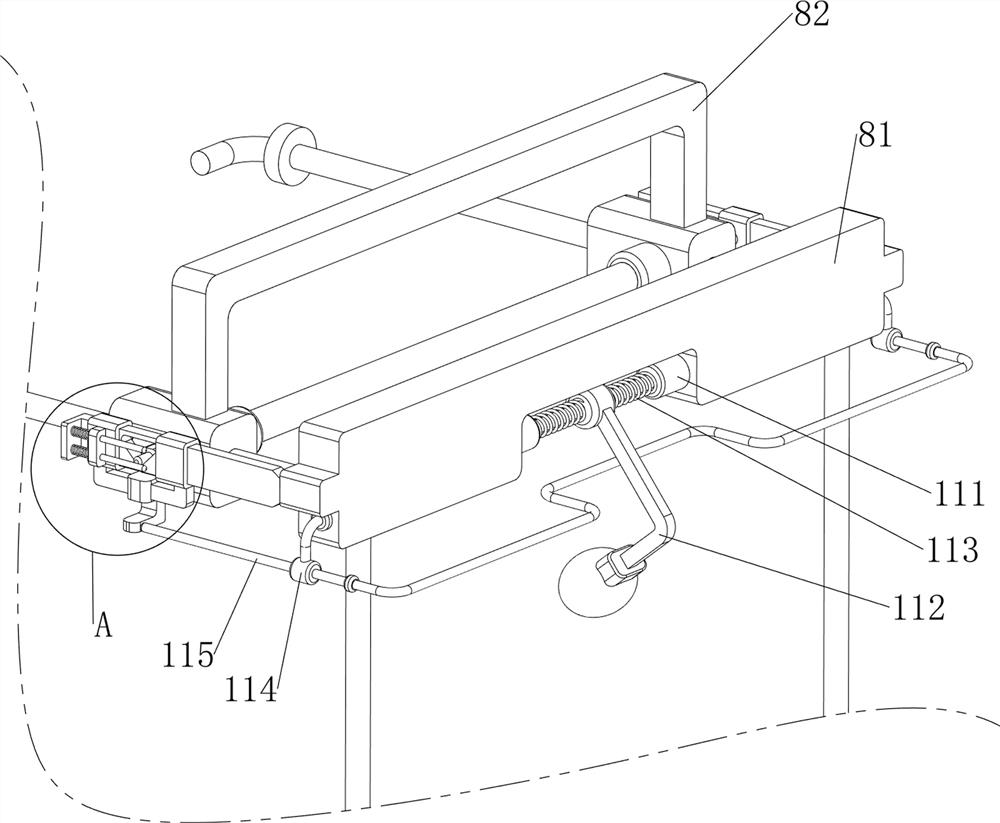

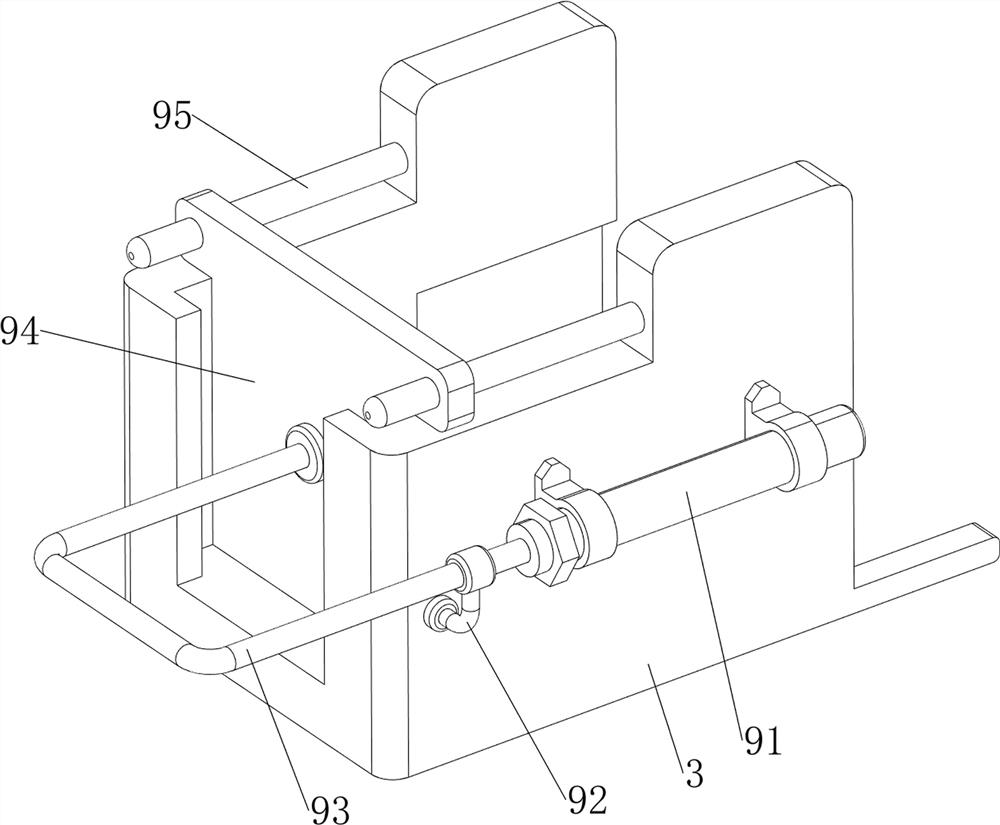

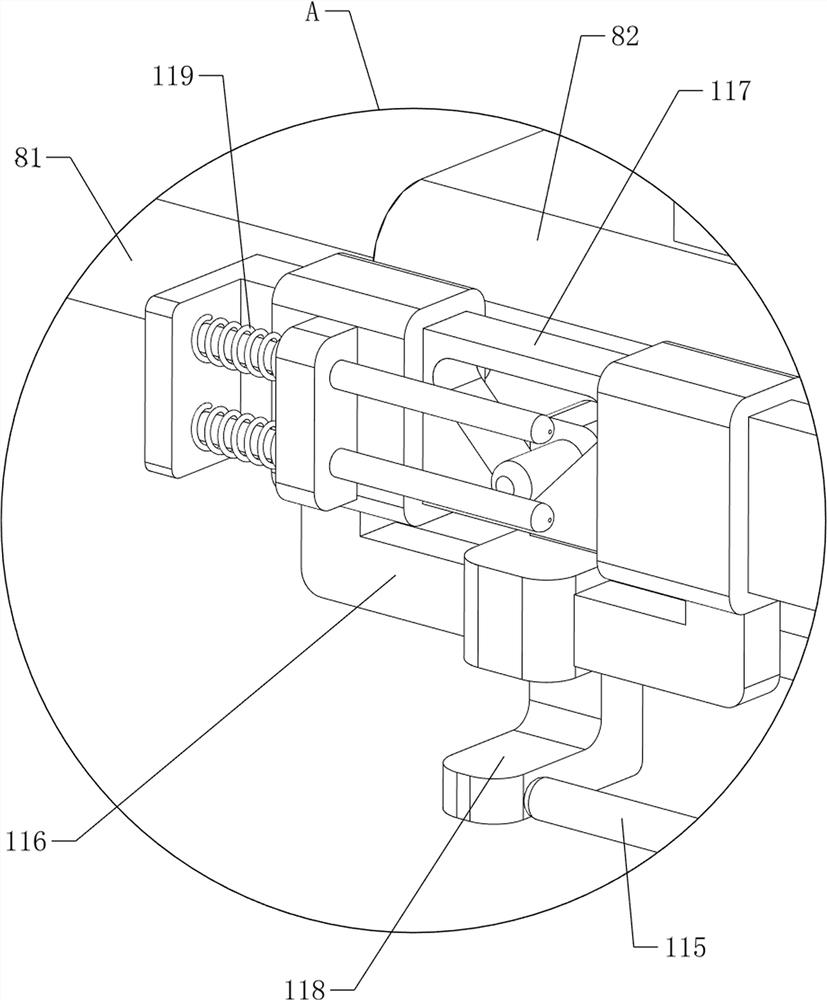

[0031] Such as Figure 1-8 The energy-saving and environment-friendly garbage processing compression block equipment shown includes a bottom plate 1, a base 2, a compression chamber 3, a blanking table 4, a briquetting block 5, a collection box 6, a pressing mechanism 7, and a first installation frame 71 , Compression cylinder 72, first bracket 73, guide rod 74, discharge mechanism 8, first slide rail 81, first slider 82, first spring 83, blanking frame 84, first gear 85, first rack 86. Feeding mechanism 9, cylinder 91, second bracket 92, push rod 93, push block 94, second slide rail 95, pushing mechanism 10, second rack 101, third bracket 102, one-way gear 103, third Rack 104, second gear 105, percussion mechanism 11, rotating sleeve 111, percussion hammer 112, second spring 113, fourth support 114, first movable rod 115, second mounting frame 116, sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com