Mouth pliers for simultaneously forming mouth and mouth edge of glass wine bottle

A wine bottle and glass technology, applied in the field of mouth pliers for machine-made glass wine bottles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

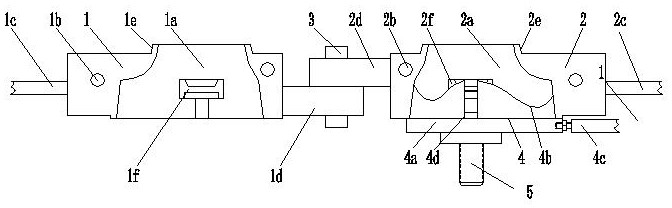

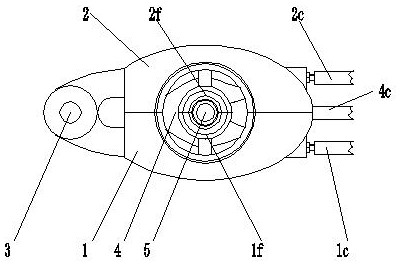

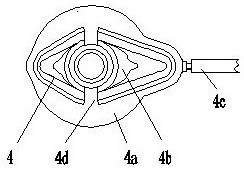

[0018] refer to figure 1 , figure 2 , image 3 , Figure 4 , a kind of mouth pliers for forming the mouth and mouth edge of a glass wine bottle at the same time. The mouth pliers are composed of an outer mold, an inner mouth mold 4 and a core 5. Die 1 and right outer mold 2 are hinged with hinge pin 3; Described left outer mold 1 is provided with mouth edge left outer surface 1a, outer mold positioning pin 1b, outer mold left handle 1c, left hinge arm 1d, and the left side of the puff plate. Interface 1e, bottle mouth left outer mold 1f; said right outer mold 2 is provided with mouth edge right outer surface 2a, outer mold positioning hole 2b, outer mold right handle 2c, right hinge arm 2d, right interface 2e of puffing plate, Bottle mouth right outer mold 2f; Described inner mouth mold 4 is provided with inner mouth mold bottom plate 4a, mouth along inner surface 4b, inner mouth mold handle 4c, guide groove 4d; Described core 5 is made of bottle mouth inner core 5a, The ...

Embodiment 2

[0020] refer to figure 1 , figure 2 , image 3 , Figure 4 , a kind of mouth pliers for forming the mouth and mouth edge of a glass wine bottle at the same time. The mouth pliers are composed of an outer mold, an inner mouth mold 4 and a core 5. Die 1 and right outer mold 2 are hinged with hinge pin 3; Described left outer mold 1 is provided with mouth edge left outer surface 1a, outer mold positioning pin 1b, outer mold left handle 1c, left hinge arm 1d, and the left side of the puff plate. Interface 1e, bottle mouth left outer mold 1f; said right outer mold 2 is provided with mouth edge right outer surface 2a, outer mold positioning hole 2b, outer mold right handle 2c, right hinge arm 2d, right interface 2e of puffing plate, Bottle mouth right outer mold 2f; Described inner mouth mold 4 is provided with inner mouth mold bottom plate 4a, mouth along inner surface 4b, inner mouth mold handle 4c, guide groove 4d; Described core 5 is made of bottle mouth inner core 5a, The ...

Embodiment 3

[0022] refer to figure 1 , figure 2 , image 3 , Figure 4 , a kind of mouth pliers for forming the mouth and mouth edge of a glass wine bottle at the same time. The mouth pliers are composed of an outer mold, an inner mouth mold 4 and a core 5. Die 1 and right outer mold 2 are hinged with hinge pin 3; Described left outer mold 1 is provided with mouth edge left outer surface 1a, outer mold positioning pin 1b, outer mold left handle 1c, left hinge arm 1d, and the left side of the puff plate. Interface 1e, bottle mouth left outer mold 1f; said right outer mold 2 is provided with mouth edge right outer surface 2a, outer mold positioning hole 2b, outer mold right handle 2c, right hinge arm 2d, right interface 2e of puffing plate, Bottle mouth right outer mold 2f; Described inner mouth mold 4 is provided with inner mouth mold bottom plate 4a, mouth along inner surface 4b, inner mouth mold handle 4c, guide groove 4d; Described core 5 is made of bottle mouth inner core 5a, The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com