Cooperative construction method for hoisting and mounting guardrail template

A construction method and collaborative technology, applied in the direction of erecting/assembling bridges, bridge parts, bridges, etc., can solve problems such as affecting the construction progress and quality of guardrail construction, bulky steel formwork, affecting construction efficiency and cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

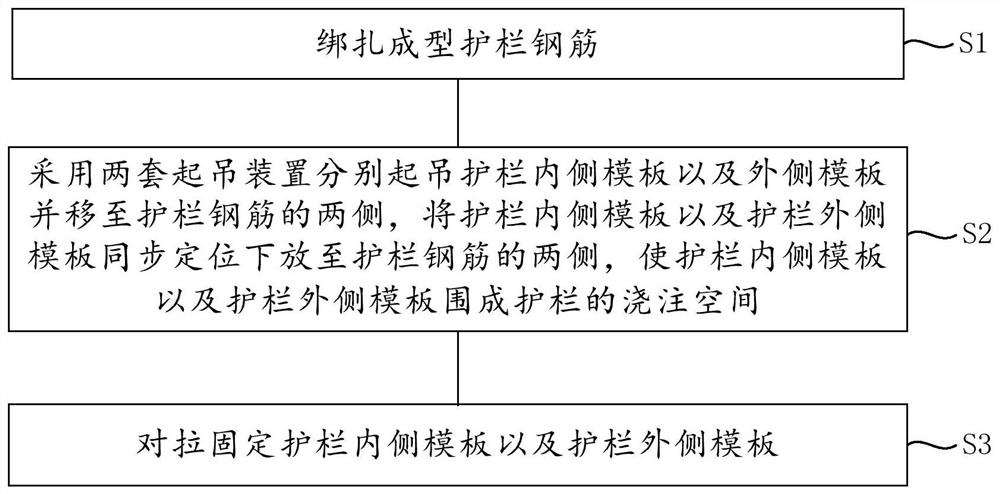

[0020] refer to Figure 1 to Figure 2 , the present invention provides a collaborative construction method for lifting and installing guardrail formwork, comprising the following steps:

[0021] Step S1: Binding the formed guardrail reinforcement;

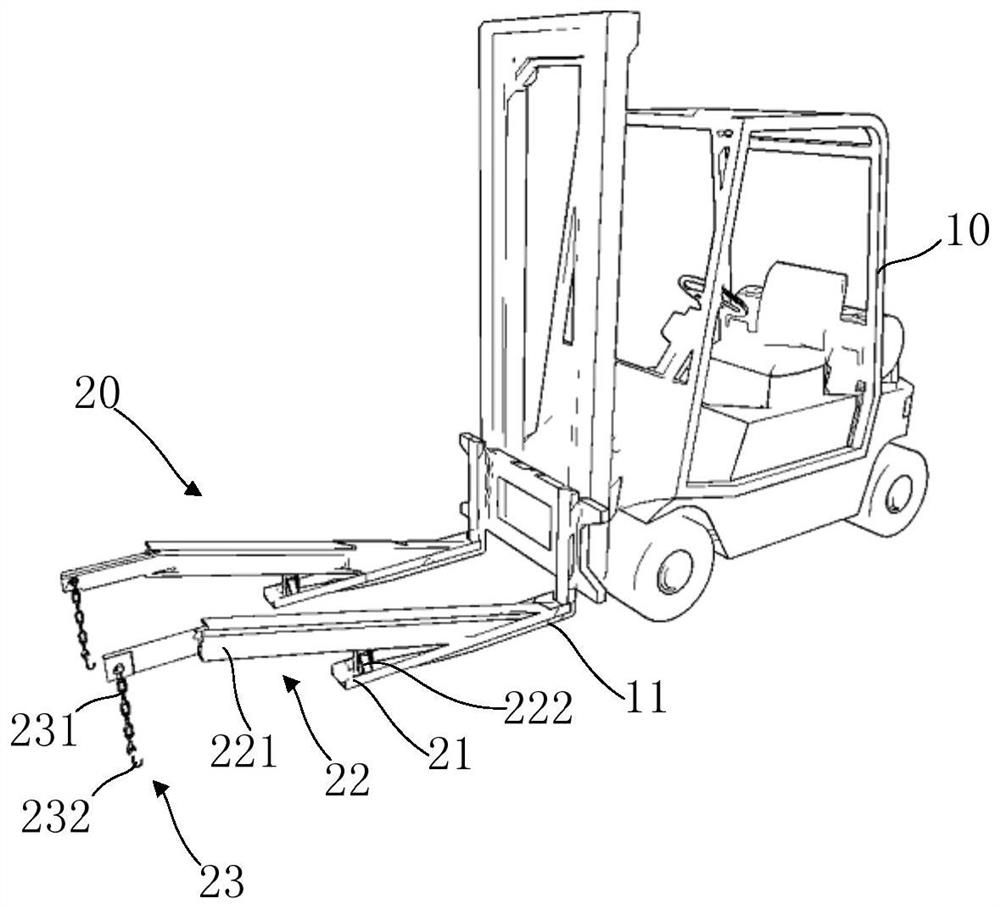

[0022] Step S2: Use two sets of lifting devices to lift the inner formwork and the outer formwork of the guardrail respectively and move them to both sides of the guardrail reinforcement. The formwork surrounds the pouring space of the guardrail;

[0023] Step S3: pulling and fixing the inner formwork of the guardrail and the outer formwork of the guardrail.

[0024] In step S2 of this embodiment, two sets of lifting devices are used to synchronize the lifting and positioning of the guardrail inner formwork and outer formwork respectively, which can greatly simplify the manual lifting and positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com