Fuse chamber interior ignition mechanism adopting detonator and space explosion suppression principle

A technology of ignition mechanism and space separation, applied in fuzes, offensive equipment, weapon accessories, etc., can solve problems such as fuze failure, safety hazards, and fuze explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

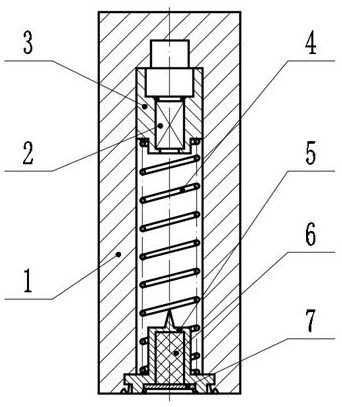

[0012] A detailed and complete description will be made below in conjunction with the accompanying drawings of the present invention.

[0013] to combine figure 1 , a kind of fuze in-bore ignition mechanism adopting the principle of detonator and space explosion-proof according to the present invention comprises a body 1, an acupuncture detonator 2, a detonator seat 3, a preload spring 4, and a fire tube; from the center of the bottom surface of the body 1 upwards There is a three-step stepped blind hole, which is the first stepped hole, the second stepped hole and the third stepped hole from top to bottom. In the stepped hole, the peripheral outer wall of the detonator seat 3 is in clearance fit with the wall of the second stepped hole, and a second-stage through hole is opened downward from the top surface of the detonator seat 3, and the fourth stepped hole and the fifth stepped hole are sequentially arranged from top to bottom. The acupuncture detonator 2 is fixed in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com