Production process of temperature-resistant lead-acid storage battery

A technology of lead-acid battery and production process, which is applied in the direction of lead-acid battery, lead-acid battery construction, secondary battery, etc., and can solve problems such as insufficient discharge capacity and shortened service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

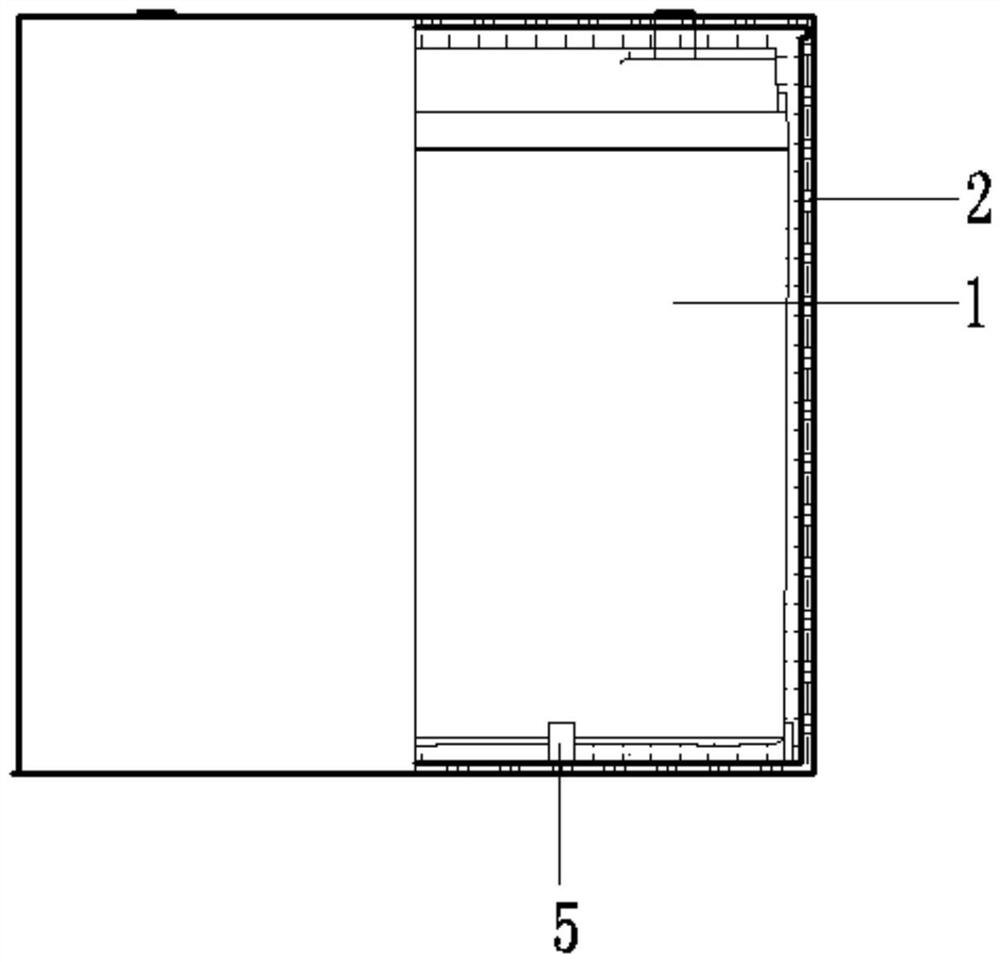

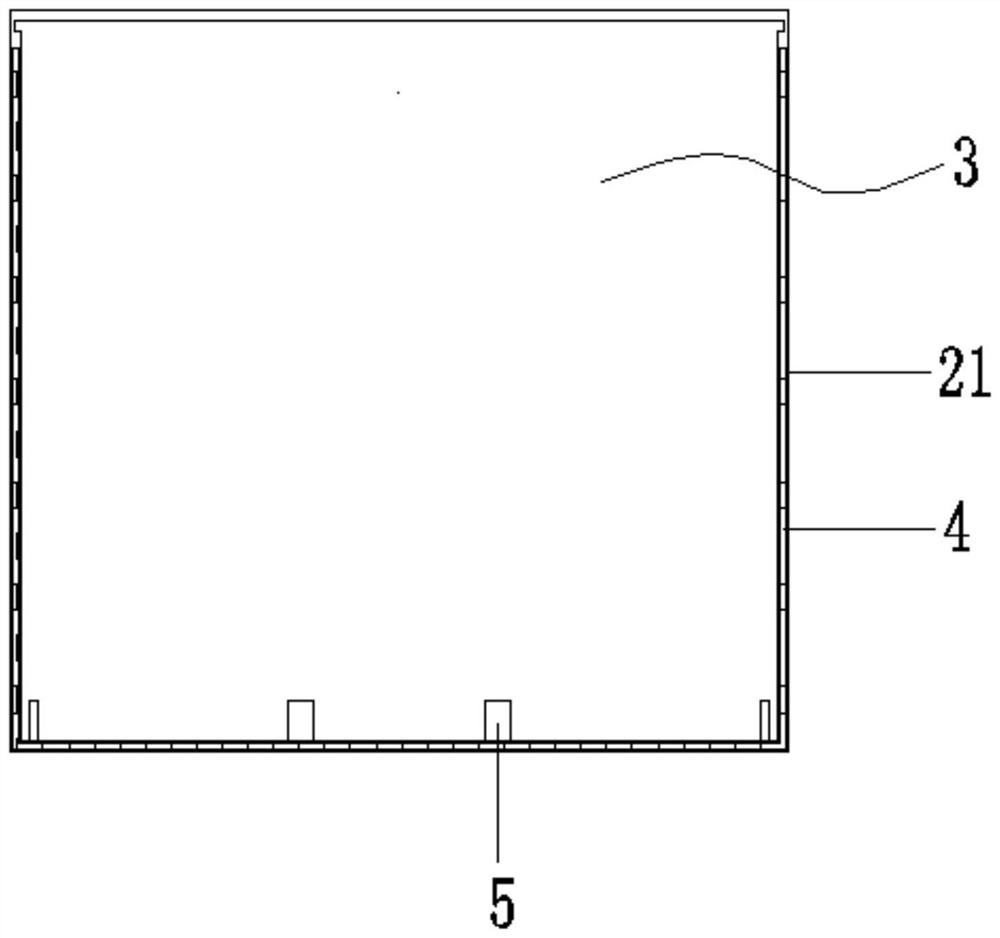

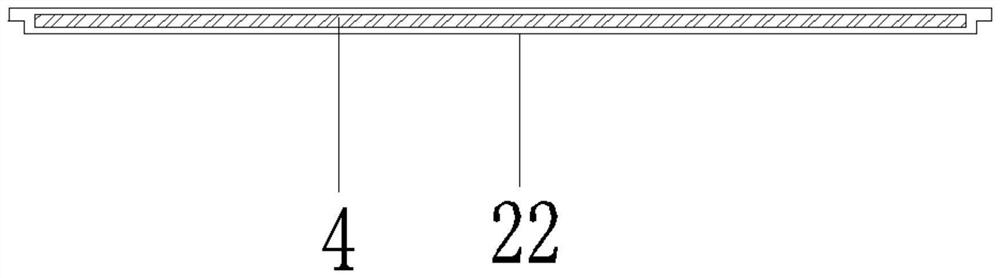

[0029] In order to further understand the content of the present invention, in conjunction with the attached Figure 1-3 And embodiment describe the present invention in detail.

[0030] The production process of a temperature-resistant lead-acid battery in this embodiment includes the following steps, S1, putting a number of cork pieces into the side wall and bottom of the battery protective shell mold respectively, and the side wall includes the side wall of the pressure surface and the side of the non-pressure surface wall, seal the mold, and then install the battery protection case mold on the injection molding machine, use ABS plastic particles and debug according to the existing injection molding process of the plastic case, and then make the battery protection case after the debugging is passed, and then carry out the battery through the injection molding process Production of the protective case; S2. Put at least one cork block into the battery protective cover mold, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com