Cable pre-tensioning device for power construction

A technology of electric power construction and pre-tensioning, applied in the direction of overhead line/cable equipment, etc., can solve the problems of poor cable effect, unstable cable, and no self-locking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

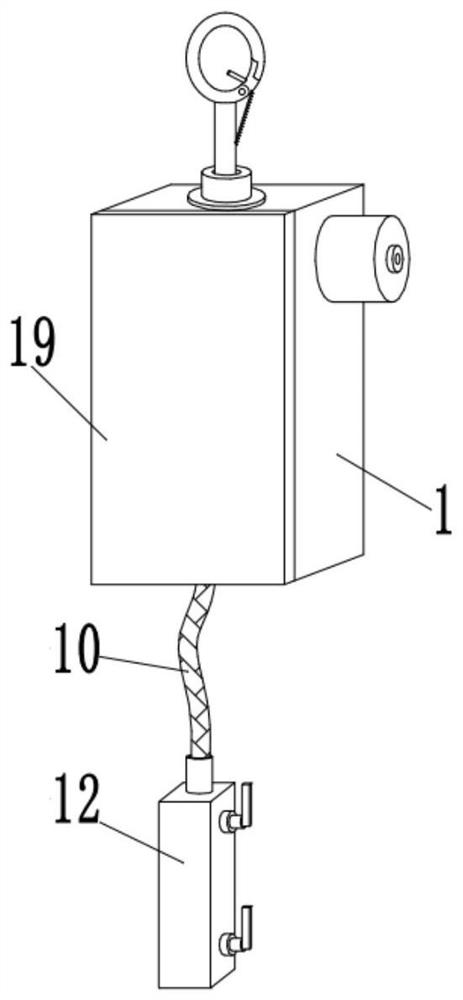

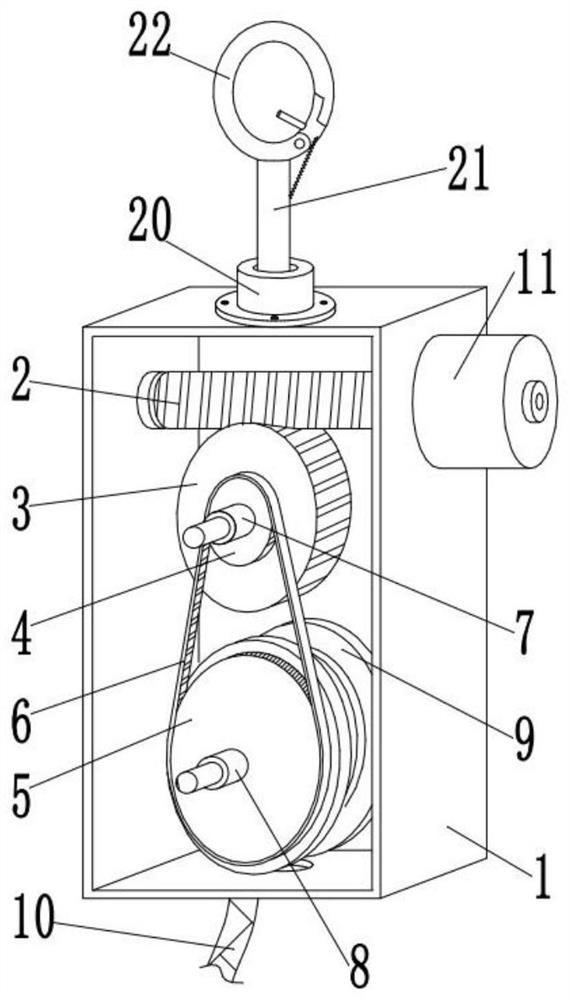

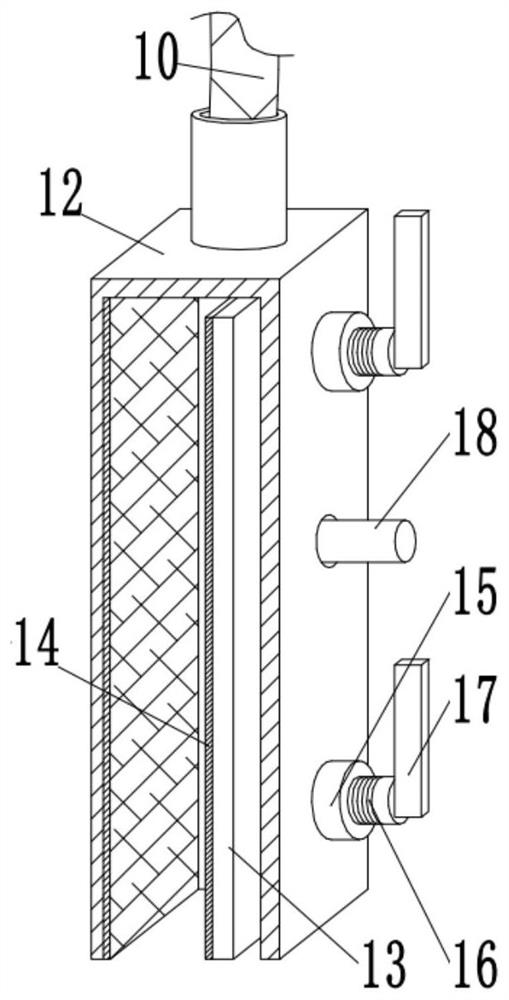

[0025] A cable pretensioning device for electric power construction, see Figure 1 to Figure 4 , including a housing 1, the inner wall of one side of the housing 1 is connected with an upper connecting shaft 7 through a bearing, and the outside of the upper connecting shaft 7 is connected with a worm wheel 3 and a driving pulley 4 through a flat key, and the inner walls of both sides of the housing 1 are passed through a bearing A worm 2 is connected, and the worm 2 meshes with the worm wheel 3. The inner wall of one side of the housing 1 is connected with a lower connecting shaft 8 through a bearing, and the outside of the lower connecting shaft 8 is connected with a winding wheel 9 and a driven pulley 5 through a flat key. Drive belt 6 is connected between the driven pulley 5 and the driving pulley 4, the driven pulley 5, the driving pulley 4 and the driving bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com