Heat dissipation device

A heat dissipation device and heat source technology, applied in heat exchange equipment, lighting and heating equipment, modification through conduction heat transfer, etc., can solve problems such as electromagnetic wave interference, copper or stainless copper oxidation, and reduced reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Reference will now be made in detail to the exemplary embodiments of the present invention, examples of which are illustrated in the accompanying drawings. Wherever possible, the same reference numbers will be used in the drawings and description to refer to the same or like parts.

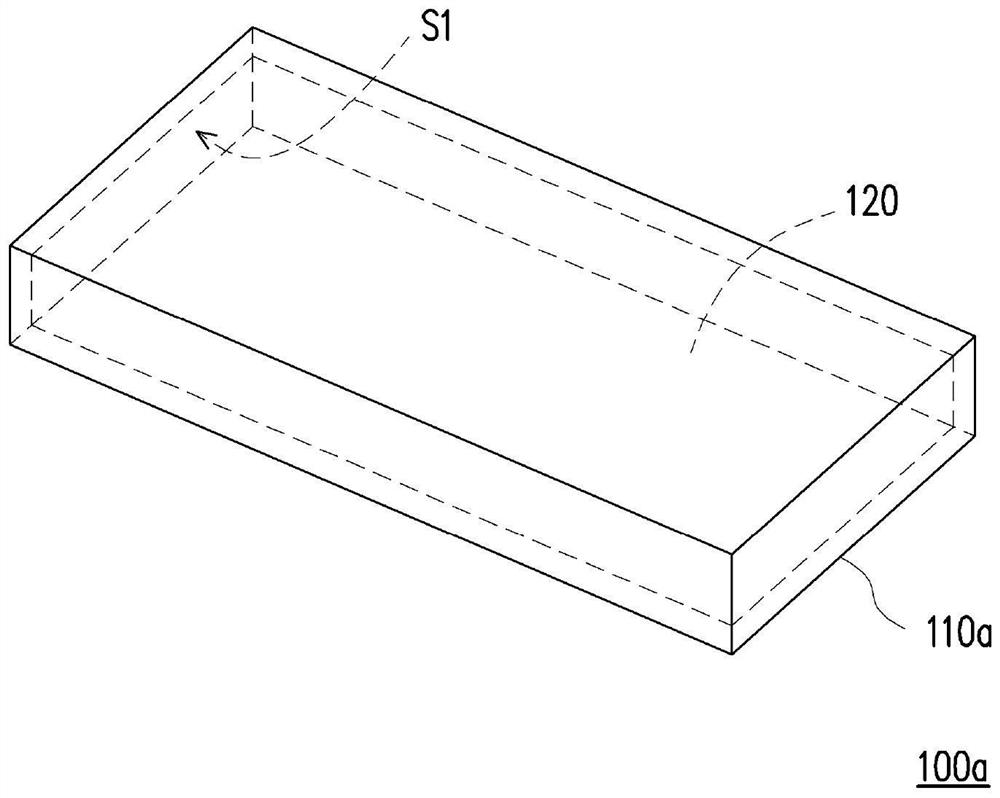

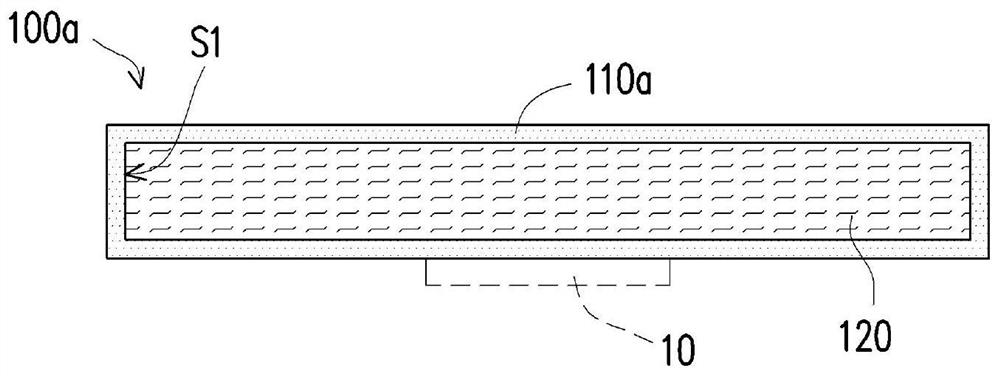

[0055] Figure 1A is a three-dimensional schematic diagram of a heat dissipation device according to an embodiment of the present invention. Figure 1B yes Figure 1A A cross-sectional schematic diagram of the heat sink. Please also refer to Figure 1A and Figure 1B, in this embodiment, the heat dissipation device 100a is suitable for dissipating heat from at least one heat source 10 in the electronic system. Here, the electronic system is, for example, a network communication system, where the main electrical specifications of the network communication system include an interface with high-speed transmission, a multi-port (Port) network switch (Ethernet switch), optical fiber communicat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com