Special feed granulating device for mutton sheep breeding

A granulation device and feed technology, applied in the direction of feed, raw material extrusion granulation, application, etc., can solve the problems of large pellet feed, increase the work intensity of workers, and cannot meet the feeding needs, and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

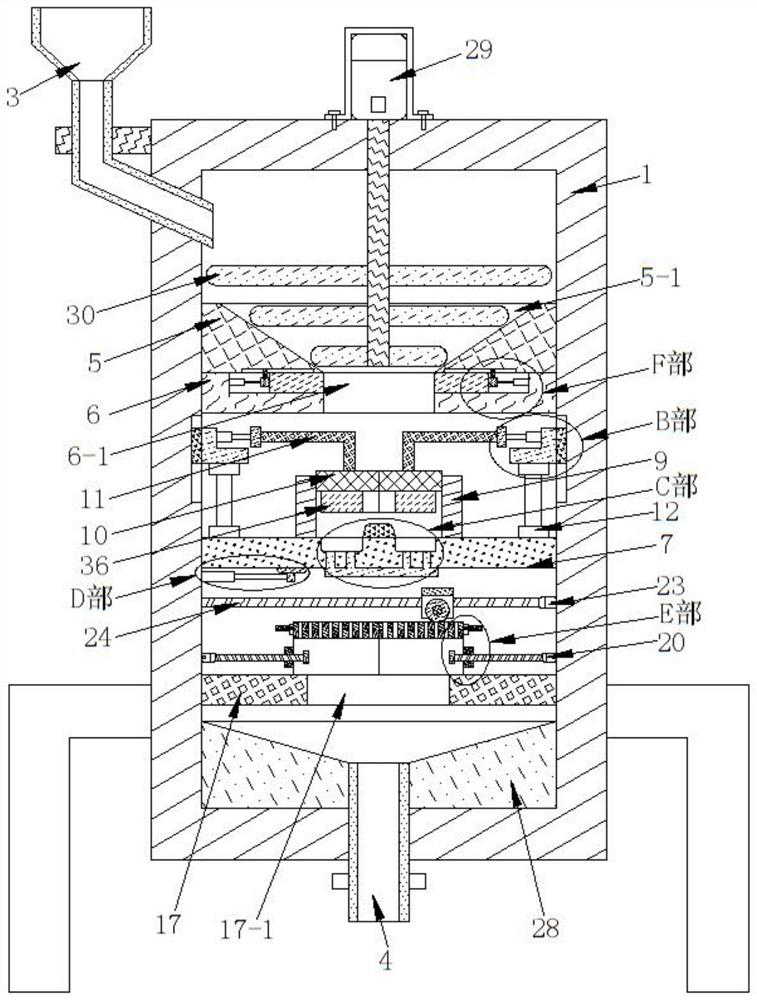

[0053] The present invention will be further described below in conjunction with the accompanying drawings.

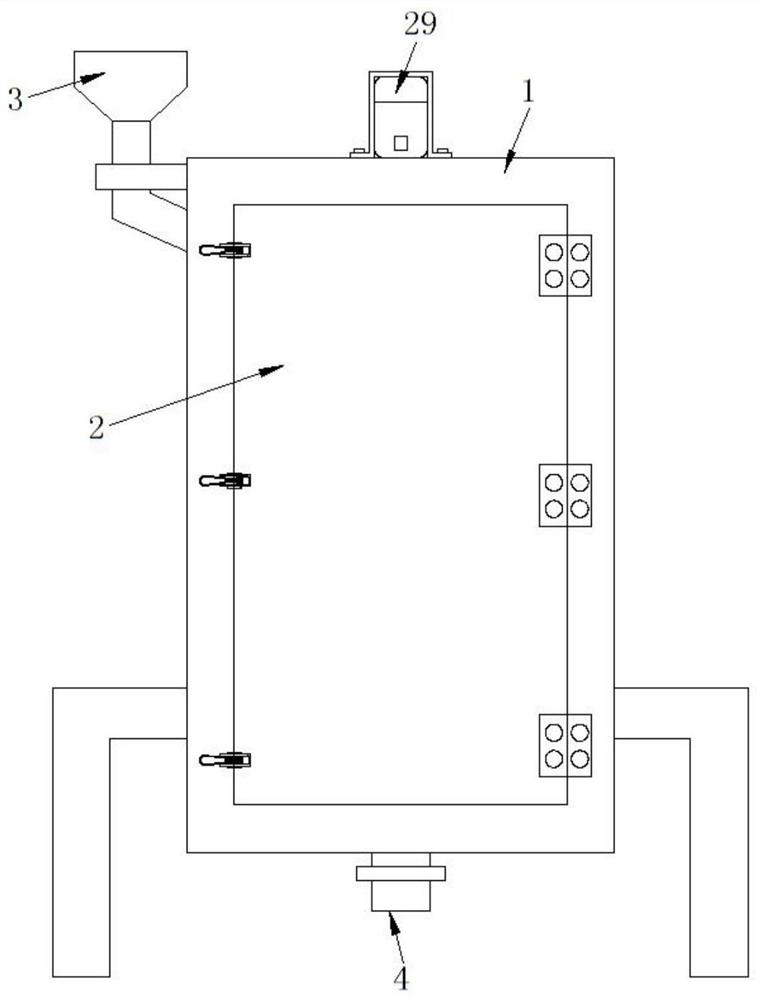

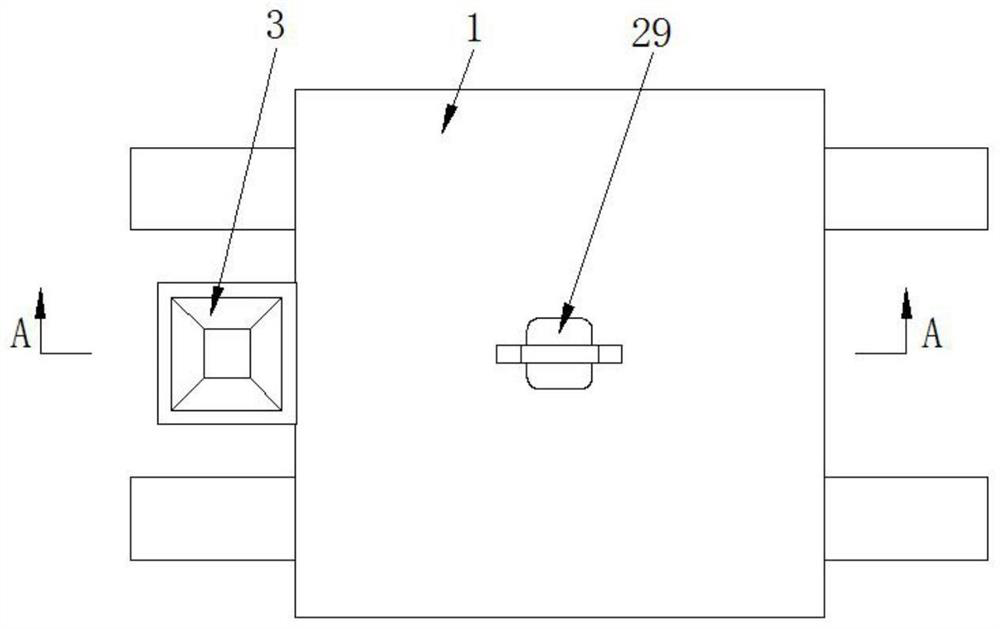

[0054] see as Figure 1-Figure 10 As shown, the technical solution adopted in this specific embodiment is: it includes a processing box body 1, a box door 2, a feed bin 3 and a discharge bin 4, and the front side of the processing box body 1 is provided with a box door 2, and the box door 2 One side of the door is hinged with the processing box 1 through a hinge, the other side of the box door 2 is connected with the processing box 1 through a buckle, and the upper left side of the processing box 1 is embedded and welded with a feed bin 3, The bottom of the processing box 1 is embedded and welded with a discharge bin 4;

[0055] It also contains:

[0056] Guide frame 5, described guide frame 5 utilizes screw to be fixedly arranged in processing box body 1, and guide frame 5 is arranged on the lower side of the discharge end of feeding bin 3, is provided with guide gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com